Anti-caking device of drum granulator

A granulator and anti-caking technology, which is applied in the direction of fertilization device, fertilizer form, granulation in the rotary tank, etc., can solve the problems of chemical fertilizer raw material bonding, etc., and achieve corrosion prevention, high production efficiency, and long-term caking avoidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

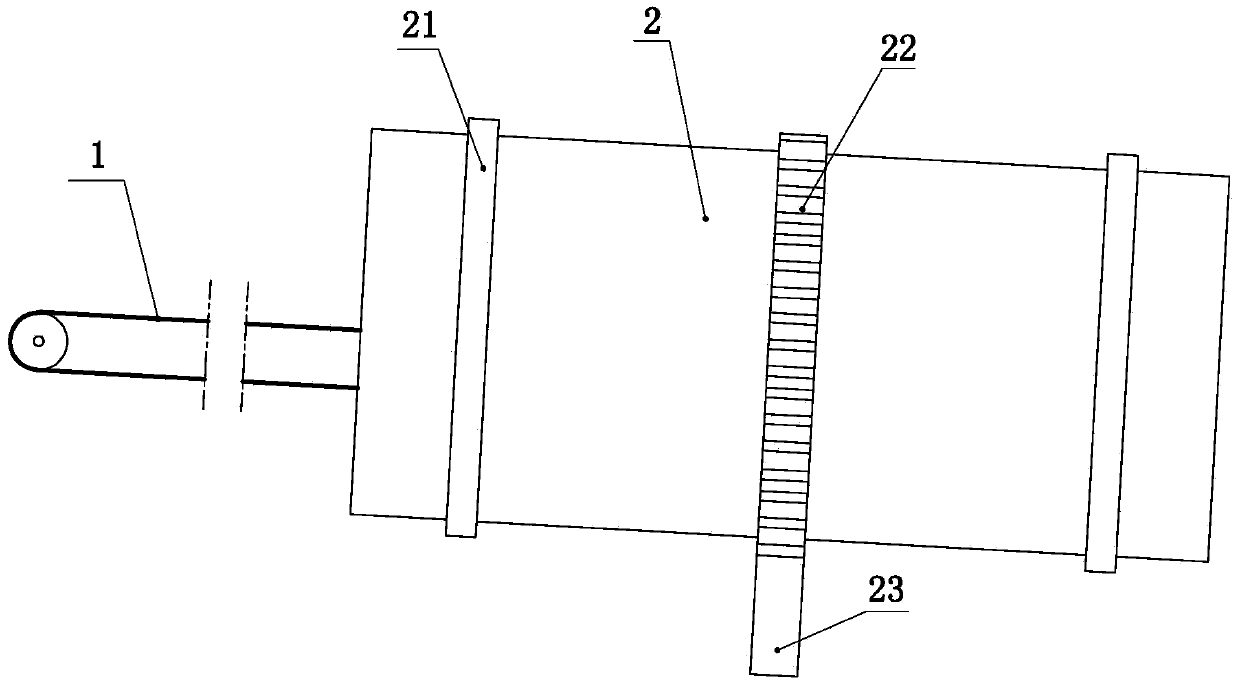

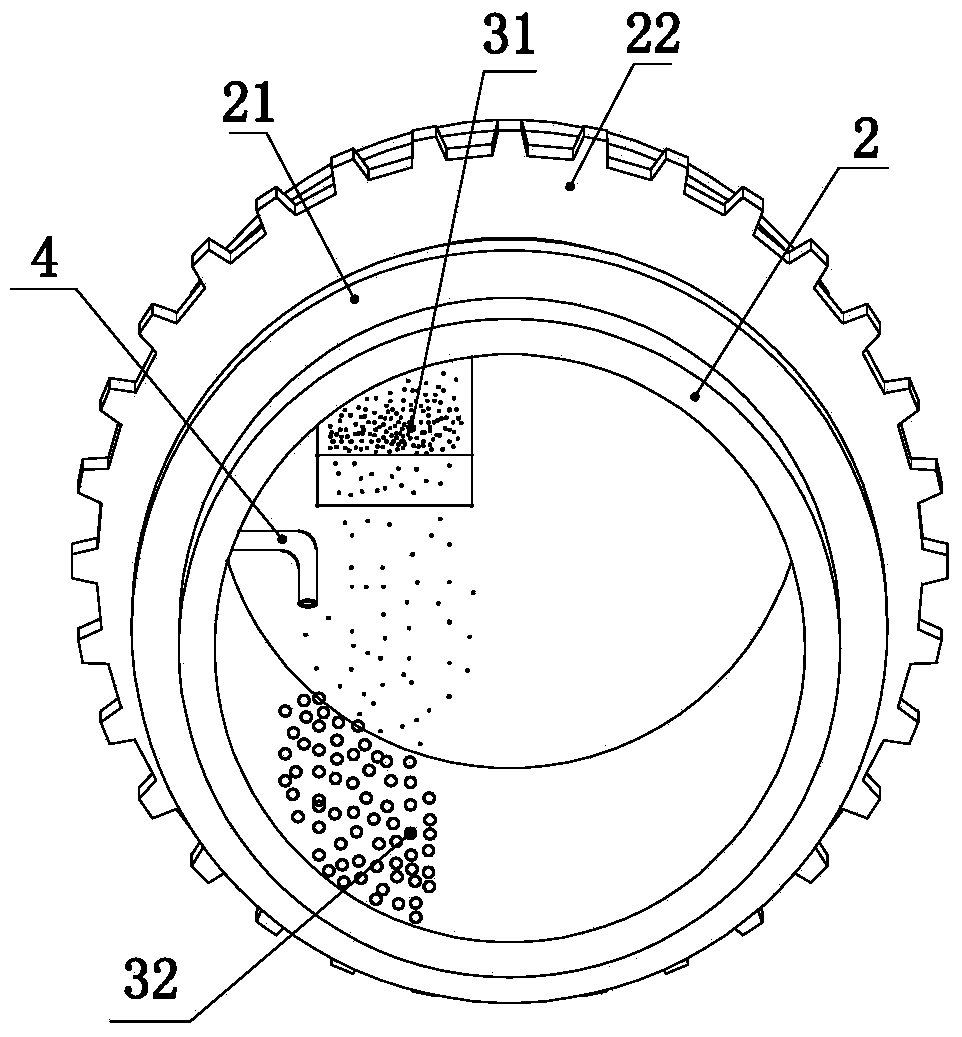

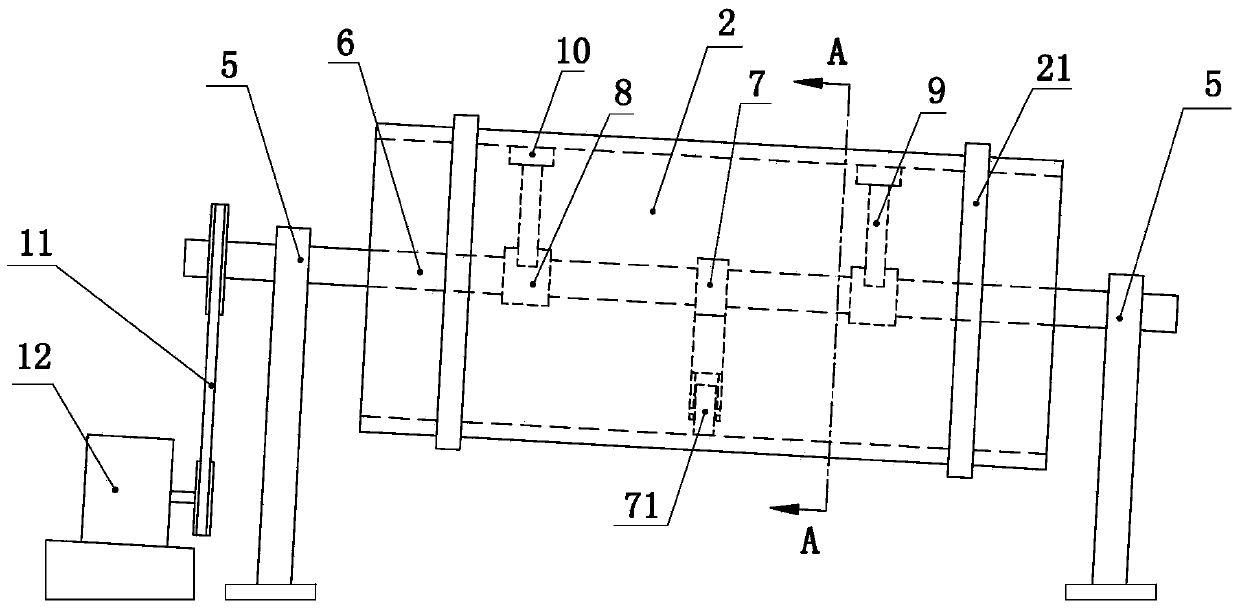

[0016] Such as Figure 3 to Figure 5 As shown, the present invention includes a frame 5, a leading screw 6, a leg 7, a roller 71, a leading screw nut 8, a support rod 9 and a scraper 10, and the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as image 3 As shown, the left and right ends of the drum 2 are respectively the raw material feed end and the fertilizer granule discharge end, and a frame 5 is respectively arranged on the left and right sides of the drum, and a threaded screw 6 is installed rotating between the tops of the two frames. The frame can be welded and fixed by section bar. The function of the frame is to support and install the lead screw. The frame with any shape and structure and capable of supporting the lead screw is within the protection scope of the present invention, and the bottom of the frame is passed through the foot Bolts are fixed to the ground. Such as Figure 4 As shown, two mutually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com