Process and apparatus for coating a controlled release product in a rotating drum

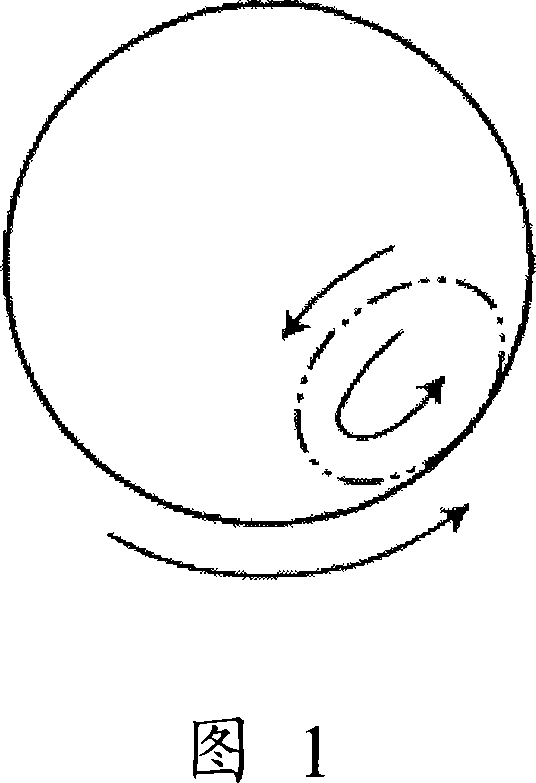

A technology of rotating rollers and rotating directions, which is applied in the direction of surface coating liquid devices, spraying devices, fertilizing devices, etc., and can solve problems such as high raw material consumption, net profit impact, and adverse effects on controlled release product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

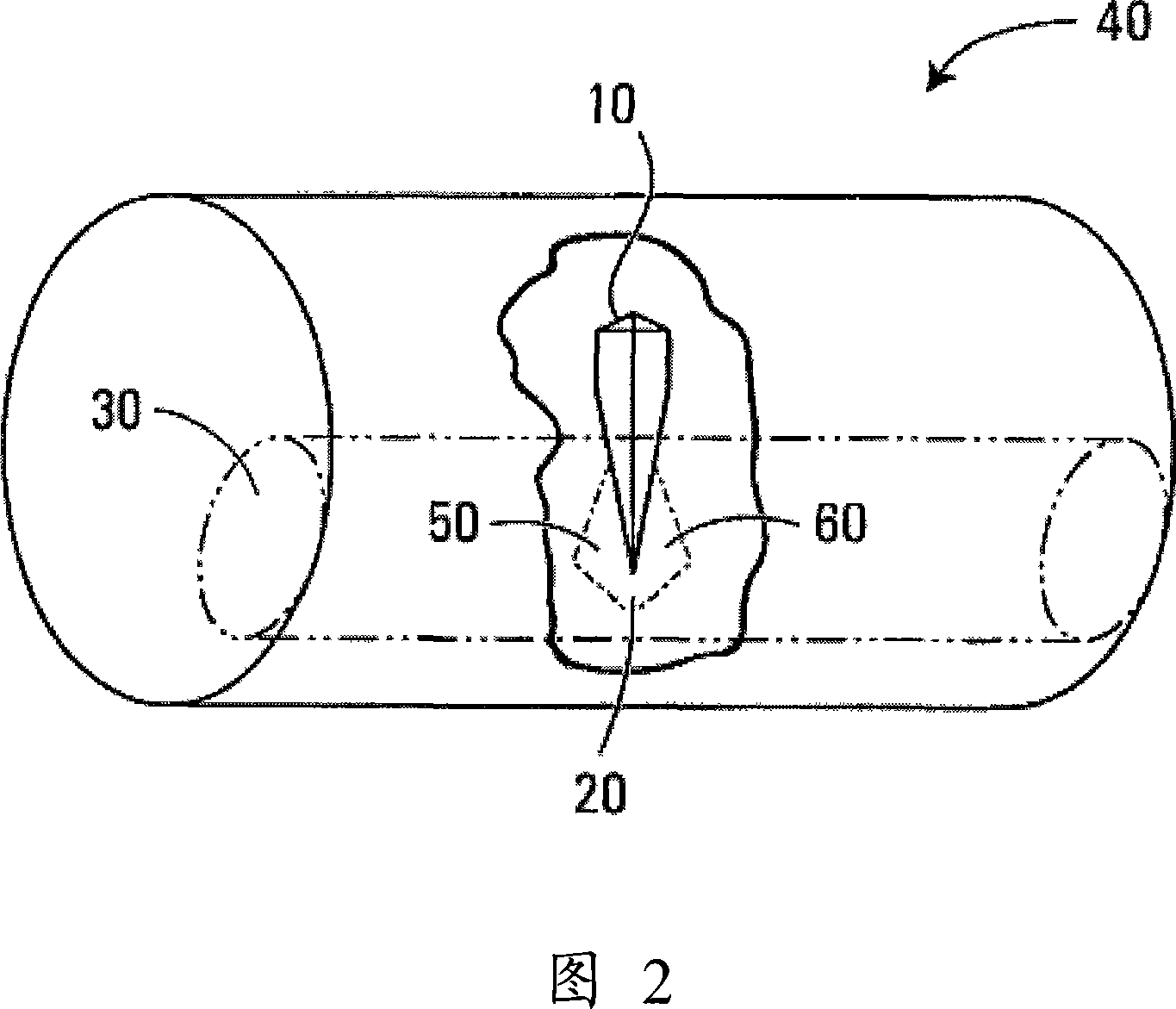

[0076] A rotating cladding unit with three cladding zones with a total of three sets of nozzles and tubes, one set for each cladding zone, was used.

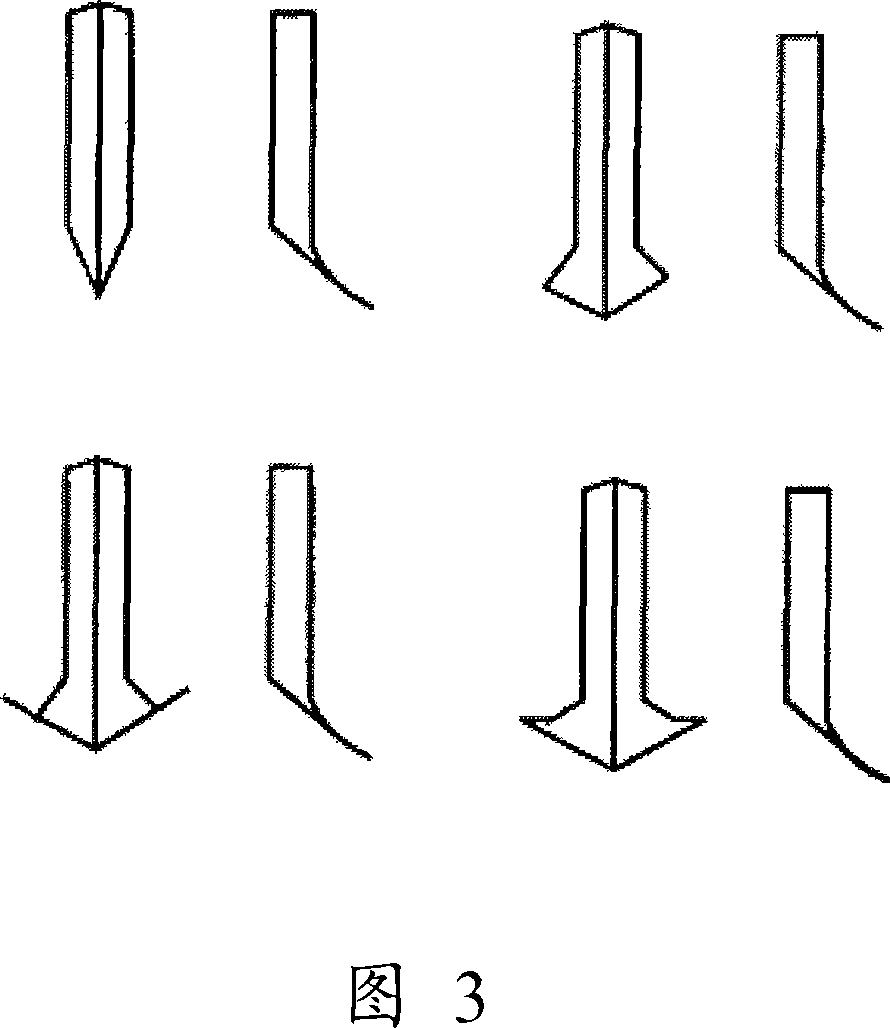

[0077] In the wet belt of the first cladding zone, the premix (comprising castor oil) and isocyanate are delivered simultaneously through pipes (ie drip or spray) from behind a curved angle iron plow tool welded into the cladding unit. Plow tools were also used in the second and third cladding areas.

[0078] The plow tool was found to contribute to a reduction in the product release rate. It was also found that by introducing the premix and isocyanate from behind the plow, the dry zone of the first cladding zone was increased from about 1 to 11 / 2 feet to about 5 feet. This increase in the drying zone is comparable to the improvement in the drying zone in the second and third sheathing zones, which would not have been possible before the addition of the plow and the feeding of the sheathing material from behind the plow. This ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com