Preparation method and application of battery grade manganese sulfate

A manganese sulfate, battery-grade technology, applied in manganese sulfate, battery electrodes, secondary batteries, etc., can solve the problems of weak participation, high cost, and difficult recovery process of precipitated slag ions, so as to reduce costs, ensure purity, Reduce the effect of the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

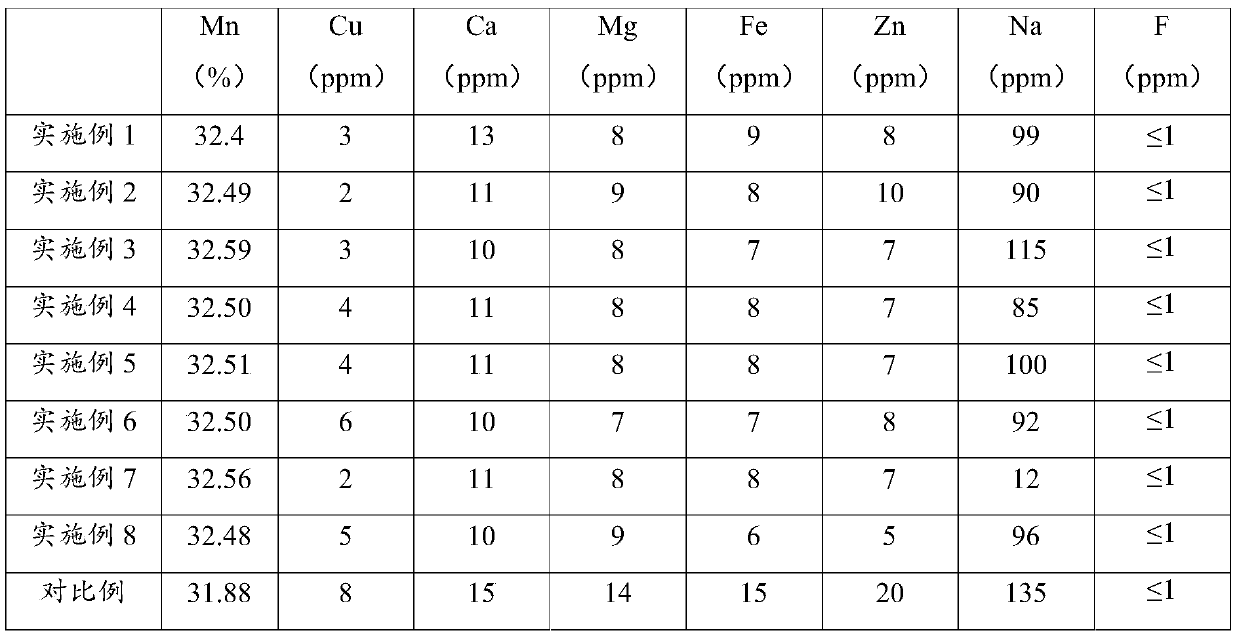

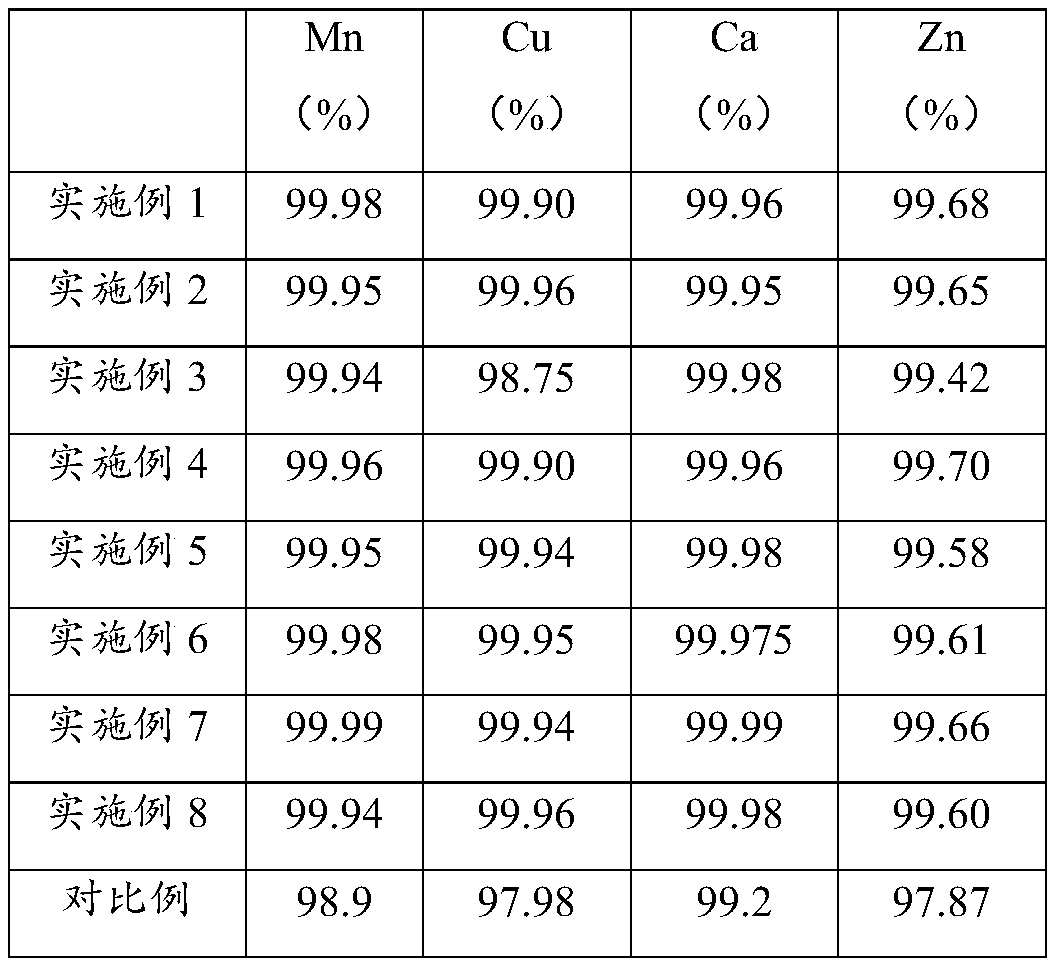

Examples

preparation example Construction

[0051] In a first aspect, in at least one embodiment, a method for preparing battery-grade manganese sulfate is provided, comprising the steps of:

[0052] (A) obtain the first filtrate after the precipitation of copper ions, calcium ions and zinc ions in the copper manganese chloride solution;

[0053] (B) under a protective atmosphere, mix the first filtrate, the manganese precipitation agent and the bottom liquid, carry out the manganese precipitation reaction, and separate the solid and liquid to obtain manganese hydroxide;

[0054] (C) Manganese hydroxide is mixed with concentrated sulfuric acid, neutralized to obtain crude manganese sulfate, and refined to obtain battery-grade manganese sulfate;

[0055] Wherein, in step (B), the manganese precipitation agent comprises ammoniacal liquor;

[0056] The base solution consists of ammonia and soluble hydroxides.

[0057] The preparation method of battery-grade manganese sulfate provided by the present invention makes full u...

Embodiment 1

[0122] The present embodiment provides a kind of preparation method of battery grade manganese sulfate, and its steps are as follows:

[0123] (1) Add solid sodium sulfate to the copper manganese chloride solution at a ratio of 110g / L, adjust the pH of the solution to 2.5, and perform a calcium precipitation reaction. After 2 hours, continue to add sodium carbonate solid, adjust the pH value of the solution to 5.0, carry out copper precipitation reaction and secondary calcium precipitation reaction, and filter after the reaction to obtain copper calcium slag and copper calcium precipitation liquid;

[0124] (2) Heat up the copper-calcium solution to 85°C, add sodium fluoride solids to 8 times the mass of calcium ions in the copper-calcium solution, adjust the pH of the solution to 5.16 with ammonium bicarbonate solid, and keep the reaction for 3 hours After filtration, calcium slag and calcium precipitated liquid are obtained;

[0125] (3) Add a sodium sulfide solution (conce...

Embodiment 2

[0129] The present embodiment provides a kind of preparation method of battery grade manganese sulfate, and its steps are as follows:

[0130] (1) Add ammonium sulfate solid to the copper manganese chloride liquid at a ratio of 80g / L, adjust the pH of the solution to 3.5, and perform a calcium precipitation reaction. After 1 hour, continue to add sodium hydroxide solid, adjust the pH value of the solution to 5.2, carry out copper precipitation reaction and secondary calcium precipitation reaction, and filter after the reaction to obtain copper-calcium slag and copper-calcium precipitation liquid;

[0131] (2) Heat up the copper-calcium solution to 70°C, add potassium fluoride solid at 10 times the mass of calcium ions in the copper-calcium solution, adjust the pH value of the solution to 6 with ammonium bicarbonate solid, and keep the reaction for 2 hours After filtration, calcium slag and calcium precipitated liquid are obtained;

[0132] (3) Add a sodium sulfide solution (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com