Concrete mixing plant stock bin dust collection device

A dust collection device and mixing station technology, which is applied in clay preparation devices, sales raw material supply devices, mixing operation control devices, etc., can solve the problems of inconvenient recycling of various raw materials, reduce the performance of dust removal devices, etc., and improve energy saving and environmental protection performance , Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

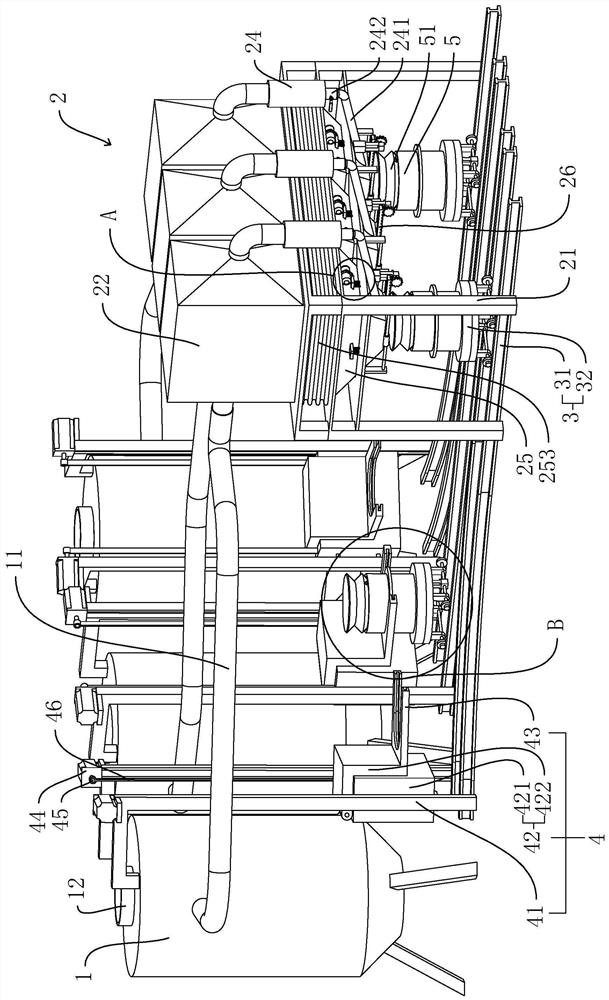

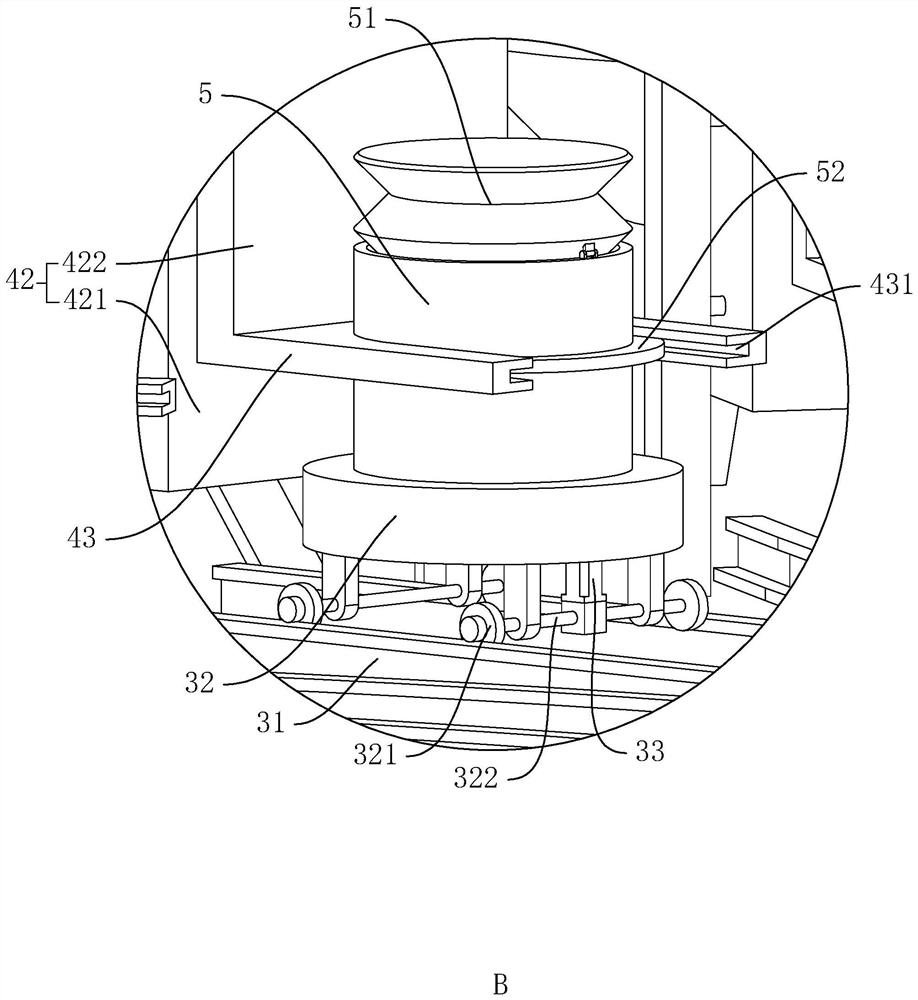

[0045] refer to figure 1 , is a dust collection device for a concrete mixing station silo disclosed by the present invention, comprising three raw material bins 1, a dust collection mechanism 2, a material conveying mechanism 3 and a material lifting mechanism 4, and the three raw material bins 1 can respectively place cement, powder Coal ash and gravel, the dust collection mechanism 2 includes the first support frame 21 arranged on the side of the raw material bin 1, the collection bin 22 arranged on the upper end of the first support frame 21 and fixedly connected with the first support frame 21, and the collection bin 22 fan 221 fixedly connected.

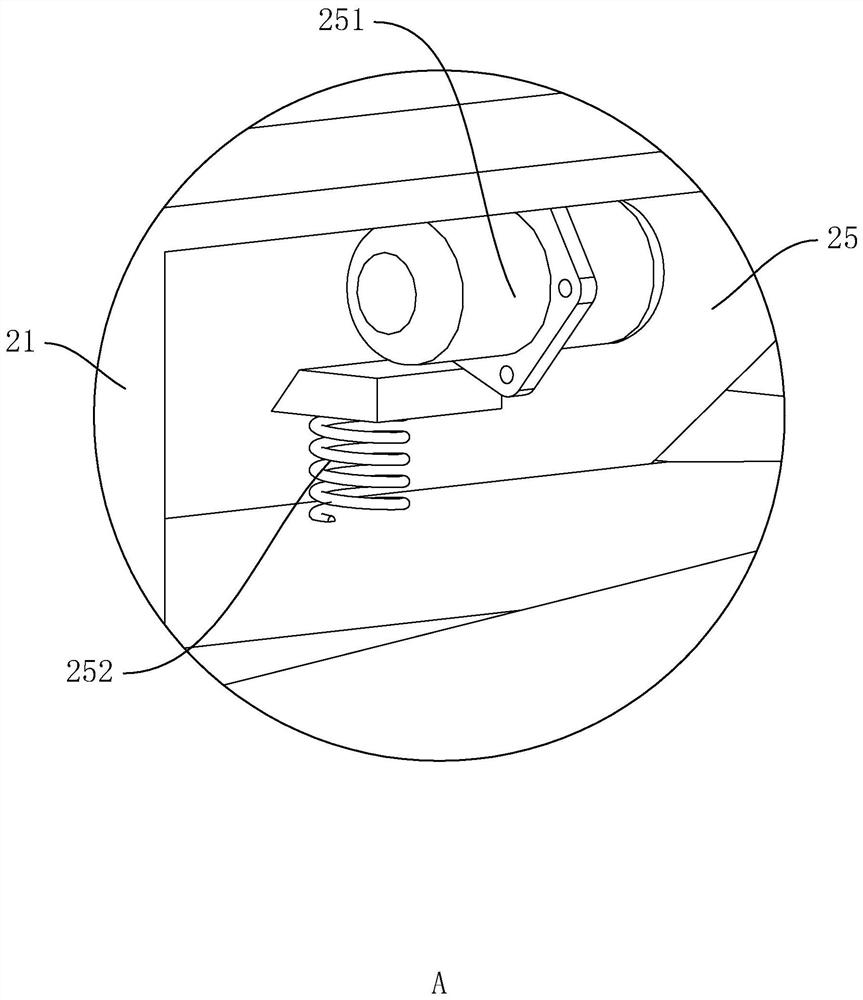

[0046] refer to figure 1 and 2 , the collection bin 22 includes three relatively independent square bins, the three raw material bins 1 are respectively connected to one end of the three bins through three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com