Water-saving system and water-saving process thereof used in wet desulfurization process

A technology of wet desulfurization and water-saving system, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., to achieve recycling, significant environmental protection effects, and simple settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

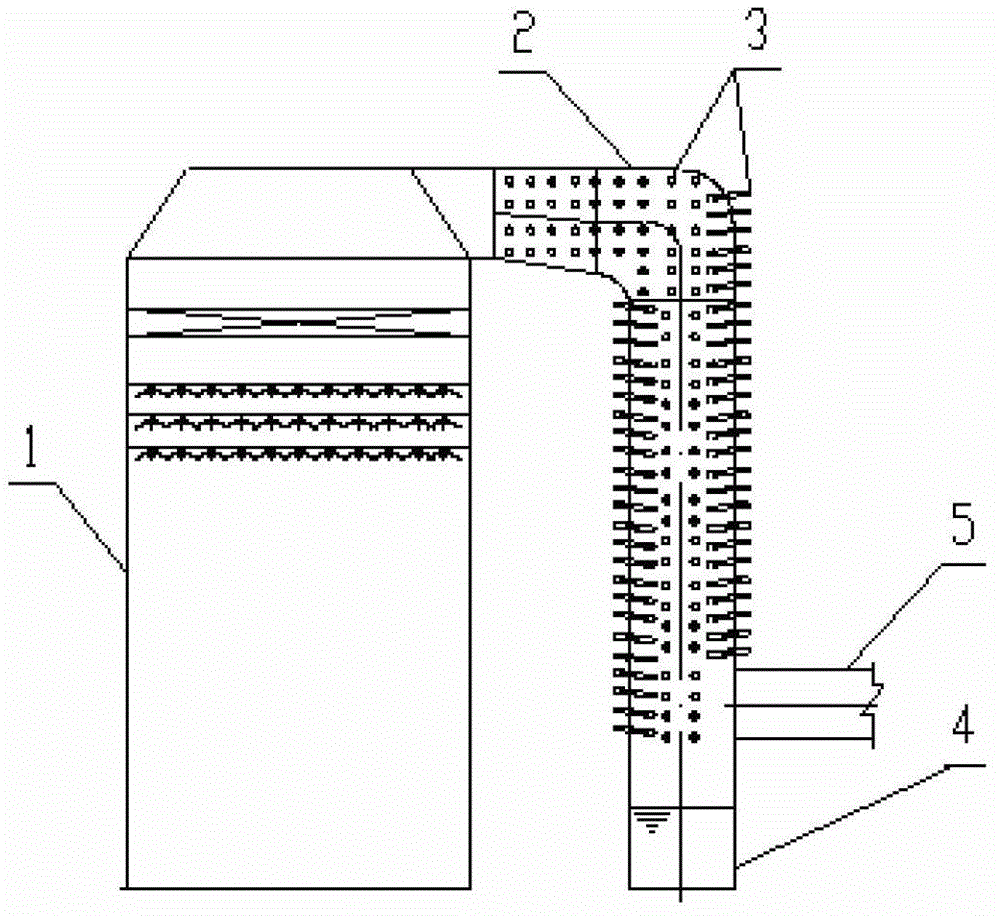

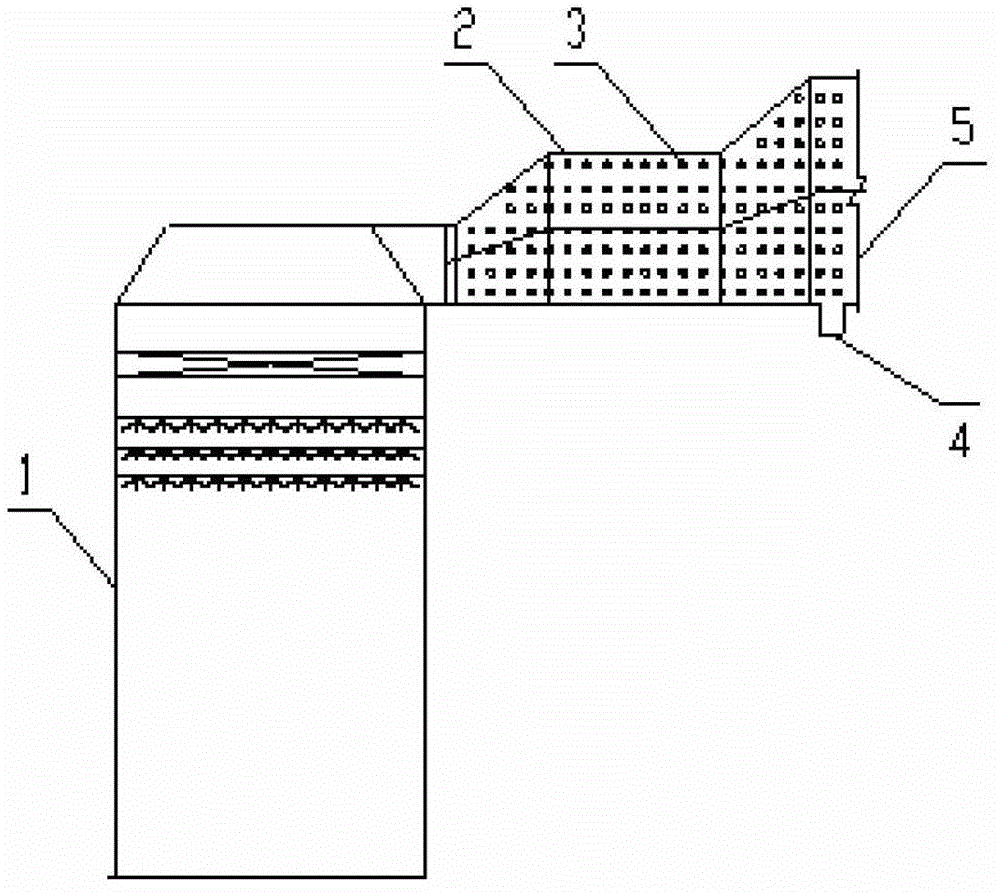

[0031] Such as figure 1 As shown, the water-saving system for the wet desulfurization process includes an absorption tower 1, a chimney 5, a clean flue 2, a plurality of heat pipes 3 arranged in sequence along the flue gas flow direction on the flue wall of the clean flue 1, and Storage device 4; wherein, the storage device 4 is arranged at the end of the clean flue 2; each heat pipe 3 is evenly distributed in the clean flue 2 and arranged obliquely, the downwardly inclined part is in the clean flue 2, and the upwardly inclined part is in the clean flue Clean flue 2 outside;

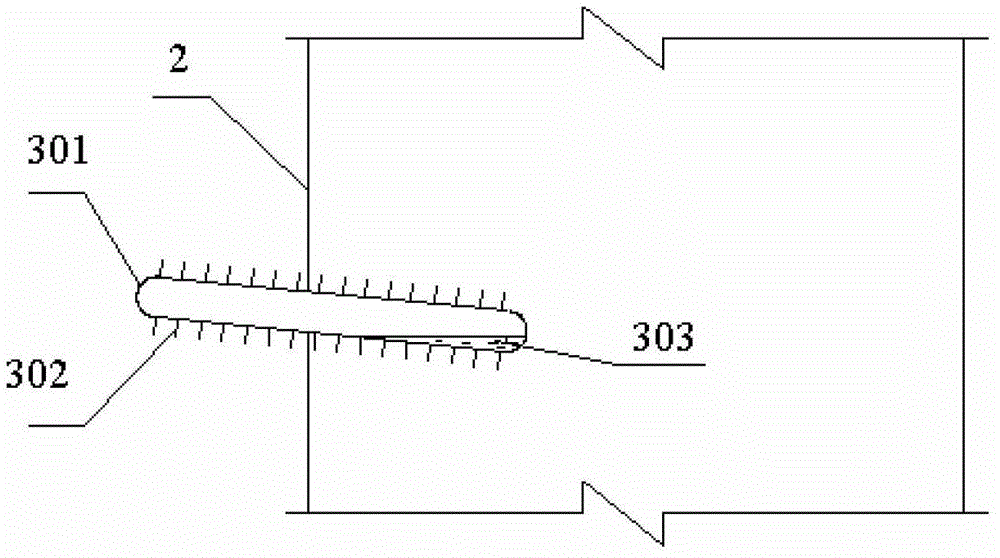

[0032] Such as figure 2 As shown, the heat pipe 3 includes a shell 301 and fins 302 arranged on the shell 301 , the fins 302 can increase the contact area accordingly, which is beneficial to improve the recovery efficiency.

[0033] In the above-described embodiment, each heat pipe 3 is not provided with fins 302 on the housing 301 in the clean flue 2, so as to prevent the dust and dirt inside the cle...

Embodiment 2

[0045] Such as figure 1 and figure 2 As shown, the setting and distribution of a water-saving system for wet desulfurization process are the same as in Example 1, except for the following settings: the specification of the clean flue 2 is 5m×6m, the diameter of the heat pipe 3 is 100mm, and the fins 302 The spacing of the heat pipes 3 is 2.5mm, the length of the heat pipes 3 in the clean flue 2 is 1.50m, and the distribution distance of the heat pipes 3 on the clean flue 2 is 400mm.

[0046] Applying the water-saving system of the present invention for wet desulfurization process to carry out the water-saving process of cleaning flue gas is the same as embodiment 1, except the following steps:

[0047] In step (1), the vacuum pressure inside the heat pipe 3 is 1×10 -4 Pa;

[0048] In step (2), the temperature of the net flue gas exiting the absorption tower 1 is 55°C, and the flue gas volume is 1.2×10 6 N m 3 / h, the ambient temperature is 5°C, the partial pressure of wa...

Embodiment 3

[0051] Such as figure 1 and figure 2 As shown, the setting and distribution of a water-saving system for wet desulfurization process are the same as in Example 1, except for the following settings: the specification of the clean flue 2 is 5m×6m, the diameter of the heat pipe 3 is 120mm, and the fins are 302 The spacing of the heat pipes 3 is 4mm, the length of the heat pipes 3 in the clean flue 2 is 2.5m, and the distribution distance of the heat pipes 3 on the clean flue 2 is 400mm.

[0052] Applying the water-saving system of the present invention for wet desulfurization process to carry out the water-saving process of cleaning flue gas is the same as embodiment 1, except the following steps:

[0053] In step (1), the vacuum pressure inside the heat pipe 3 is 10Pa;

[0054] In step (2), the temperature of the net flue gas exiting the absorption tower 1 is 60°C, and the flue gas volume is 1.5×10 6 N m 3 / h, the ambient temperature is 15°C, the partial pressure of water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com