Corner tube type forced circulating coal powder burning hot water boiler

A forced circulation, hot water boiler technology, applied in the field of hot water boilers, can solve the problems of reduced heat absorption efficiency, poor combustion flue design, unfavorable land use efficiency, etc., to achieve compact structure, improve heat utilization rate and heat supply. Efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

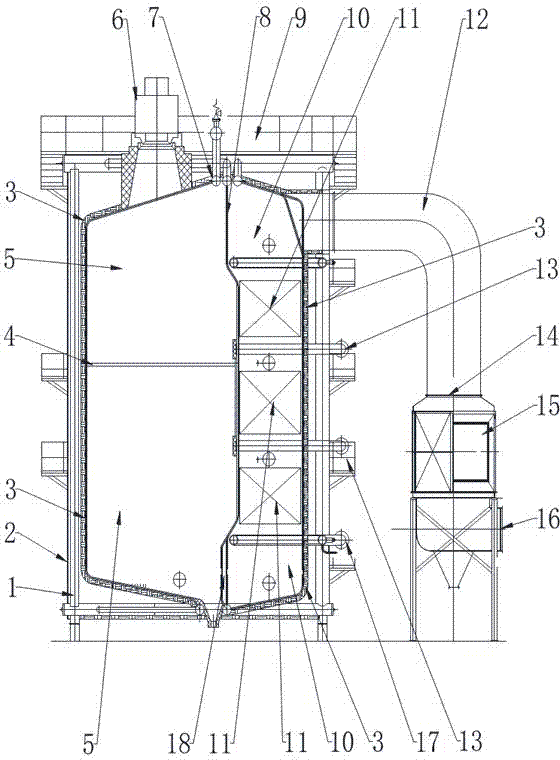

[0028] Such as figure 1 As shown, the present embodiment is a corner tube forced circulation pulverized coal-fired hot water boiler, which includes a furnace body 2, a combustion chamber 5 and a heating chamber 10 arranged side by side in the furnace body 2, and the combustion chamber 5 and the heating chamber 10 are arranged side by side. Separated by a vertical membrane water cooling screen 8, the lower end of the membrane water cooling screen 8 is provided with a flue gas flow port 18 for passing the flame and smoke in the combustion chamber 5 into the heating chamber 10; the upper end of the combustion chamber 5 A pulverized coal burner 6 is provided, and three convective heating surfaces 11 of serpentine tubes arranged side by side are arranged in the heating chamber 10; the flame and flue gas burned by the pulverized coal burner 6 are fully burned in the combustion chamber 5, and the secondary air structure 4 Blast again to make fuel burn fully, reduce the formation of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com