Metal cutting device for machining center and working method of metal cutting device

A metal cutting and machining center technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of inability to separate chips from cooling liquid, recycling of cooling liquid and chips, and effective treatment of cooling liquid and other issues to achieve the effect of improving quality inspection efficiency, saving costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

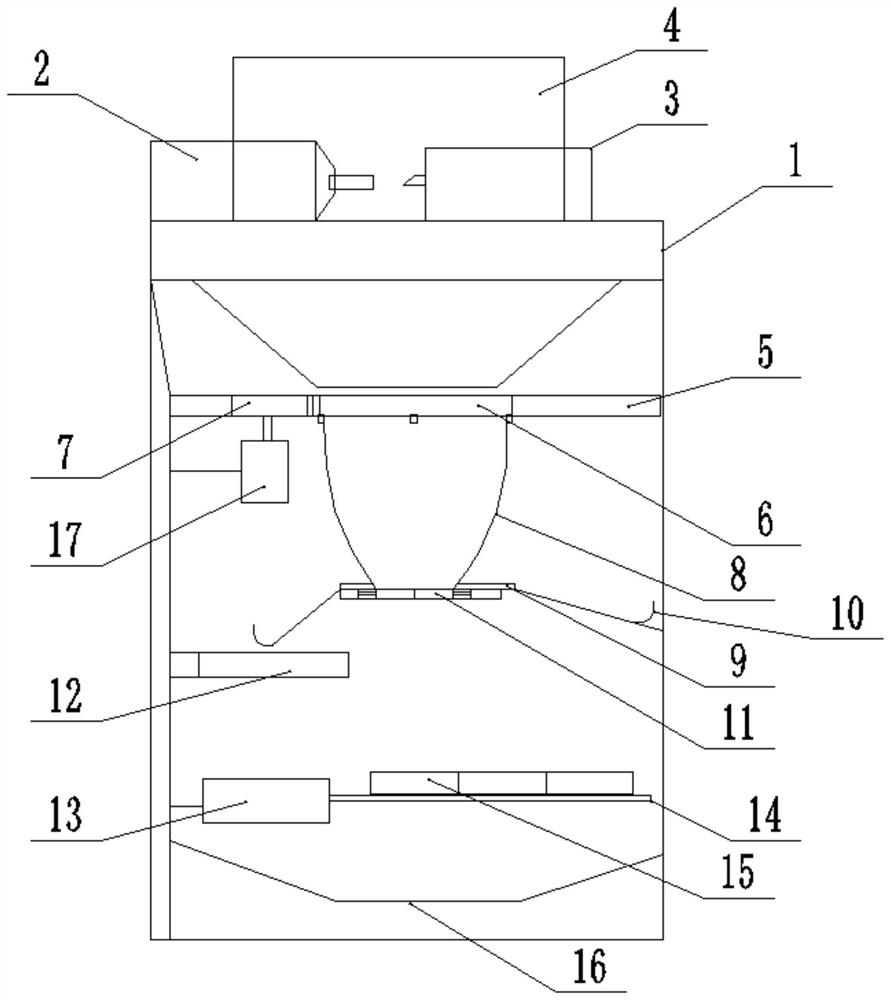

[0055] like Figure 1-3 As shown, a metal cutting device for a machining center includes a cutting mechanism, a collecting mechanism, and a filtering mechanism; wherein:

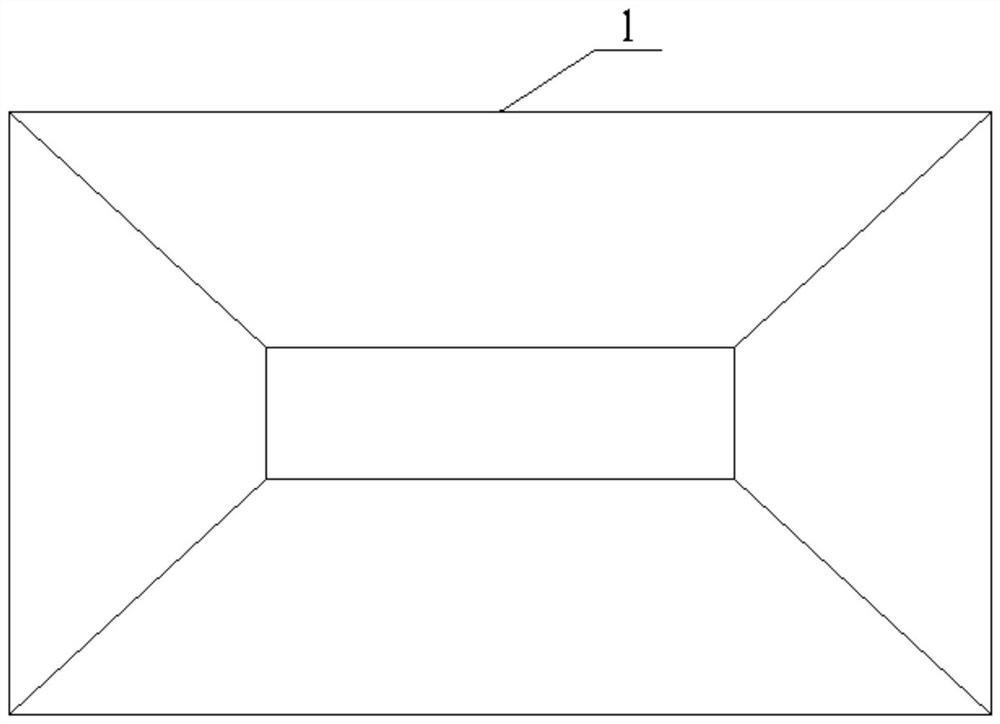

[0056] The cutting mechanism includes a frame 1, the middle of the frame 1 is a hollow structure, and the top of the frame 1 is provided with two symmetrical sliding rails along the length direction;

[0057] The clamping pile head 2 is fixedly installed on one side of the top of the frame 1, and the end of the clamping pile head 2 is provided with a chuck for clamping the workpiece;

[0058] The cutting pile head 3 is slidably installed on the top of the frame 1, and the cutting pile head 3 is provided with a cutting tool and a coolant nozzle; the coolant nozzle is aligned with the position where the cutting occurs, and is used for cooling the tool;

[0059] Protective cover 4, the protective cover 4 is in the shape of a long strip and is slidably connected to the slide rail. The protective cover 4 covers ...

Embodiment 2

[0080] In order to better understand the working principle or working process of the metal cutting device for a machining center provided in Embodiment 1, the working method of the metal cutting device for a machining center is described in detail in Embodiment 2.

[0081] Specifically, the specific steps of the working method of the metal cutting device for a machining center are as follows;

[0082] S1, load the workpiece, fix the workpiece to be cut on the clamping pile head 2, fix the tool on the cutting pile head 3, and adjust the position of the tool and the workpiece to facilitate cutting;

[0083] S2, adjust the position of the protective cover 4, slide the position of the protective cover 4 along the slide rail, and cover the cutting position;

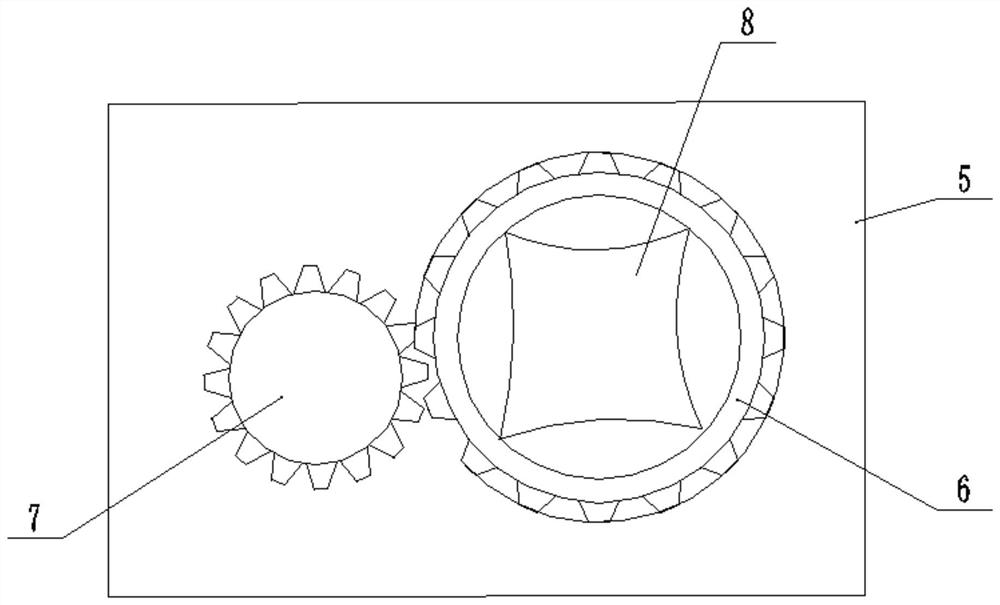

[0084] S3, start the equipment to cut the workpiece, and start the coolant at the same time to cool down during cutting; the chips generated during cutting enter the filter mechanism along the conical funnel,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com