A method for desiliconization and arsenic removal of spent SCR catalyst

An SCR catalyst and arsenic removal technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low removal rate, no mention of silicon treatment, low arsenic removal rate, etc. The effect of low leaching rate, raw material and operating cost, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

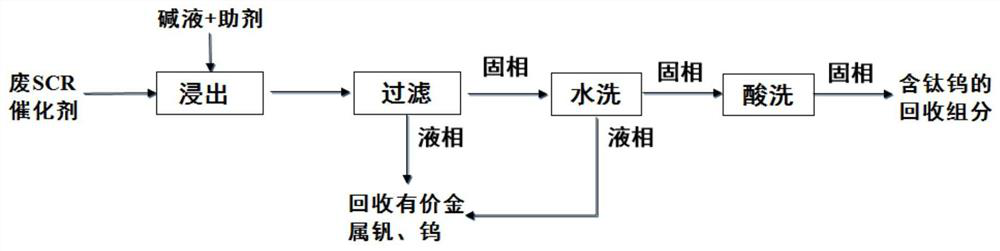

[0051] This embodiment provides a method for removing arsenic and desiliconization from a spent SCR catalyst. The content of arsenic in the spent SCR catalyst is 2.2wt%, and the content of silicon dioxide is 4.23wt%. The process flow chart of the method is as follows figure 1 shown, including the following steps:

[0052] (1) Add the spent SCR denitrification catalyst broken to 100 meshes into NaOH solution containing hydrogen peroxide for leaching, the concentration of NaOH solution is 20wt%, the concentration of hydrogen peroxide is 3wt%, and the mass ratio of leaching liquid to solid is 2:1. Leach for 4h at a stirring rate of 200r / min, and then filter;

[0053] (2) The solid phase obtained by filtering in step (1) is washed with water and pickled in turn, and the acid used is sulfuric acid, and then dried at 100°C for 12 hours to obtain a recovered component containing titanium and tungsten, which is used for the preparation of SCR catalyst; The liquid phase continues to b...

Embodiment 2

[0056] This embodiment provides a method for removing arsenic and desiliconization from a spent SCR catalyst. The arsenic content in the spent SCR catalyst is 1.63wt%, and the silicon dioxide content is 4.35wt%. The method includes the following steps:

[0057] (1) Add the waste SCR denitrification catalyst broken to 200 meshes into NaOH solution containing sodium persulfate for leaching, the concentration of NaOH solution is 16wt%, the concentration of sodium persulfate is 5wt%, and the mass ratio of leaching liquid to solid is 4:1, Leach at 75°C for 3 hours at a stirring rate of 300r / min, and then filter;

[0058] (2) The solid phase obtained by filtering in step (1) is washed with water and pickled in sequence, and the acid used is hydrochloric acid, and then dried at 80°C for 15 hours to obtain a recovered component containing titanium and tungsten, which is used for the preparation of SCR catalyst; The liquid phase continues to be separated for the recovery of vanadium an...

Embodiment 3

[0061] This embodiment provides a method for removing arsenic and desiliconization from a spent SCR catalyst. The content of arsenic in the spent SCR catalyst is 0.17wt%, and the content of silicon dioxide is 4.5wt%. The method includes the following steps:

[0062] (1) Add the spent SCR denitrification catalyst broken to 300 meshes into the KOH solution containing potassium persulfate for leaching, the concentration of the KOH solution is 10wt%, the concentration of potassium persulfate is 1wt%, and the mass ratio of the leaching liquid to solid is 5:1, Leach at 60°C for 5 hours at a stirring rate of 250r / min, and then filter;

[0063] (2) The solid phase obtained by filtering in step (1) is washed with water and pickled in sequence, and the acid used is nitric acid, and then dried at 120°C for 6 hours to obtain a recovered component containing titanium and tungsten, which is used for the preparation of SCR catalyst; The liquid phase continues to be separated for the recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com