Vertical type continuous separating drying device for aluminum-plastic composite package material

A packaging material, aluminum-plastic composite technology, applied in the direction of plastic recycling, recycling technology, grain processing, etc., can solve the problem of incomplete physical separation of aluminum and plastic, to facilitate industrial promotion and application, reduce consumption, and good promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

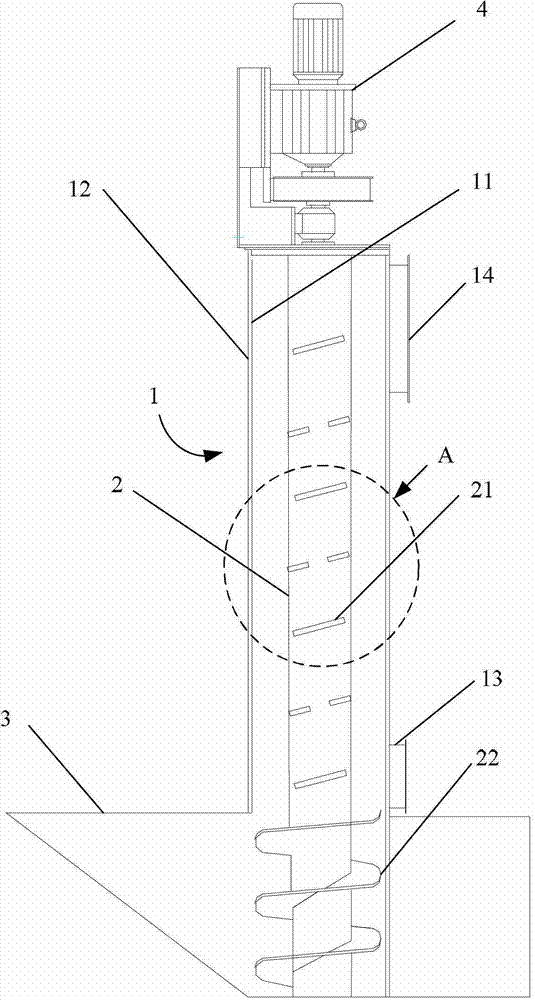

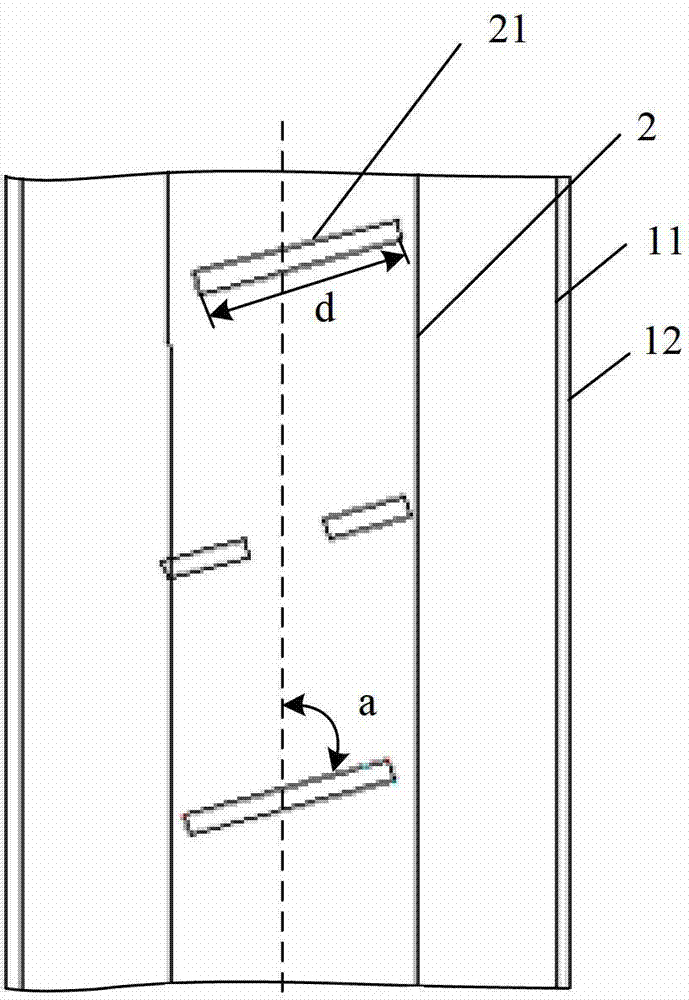

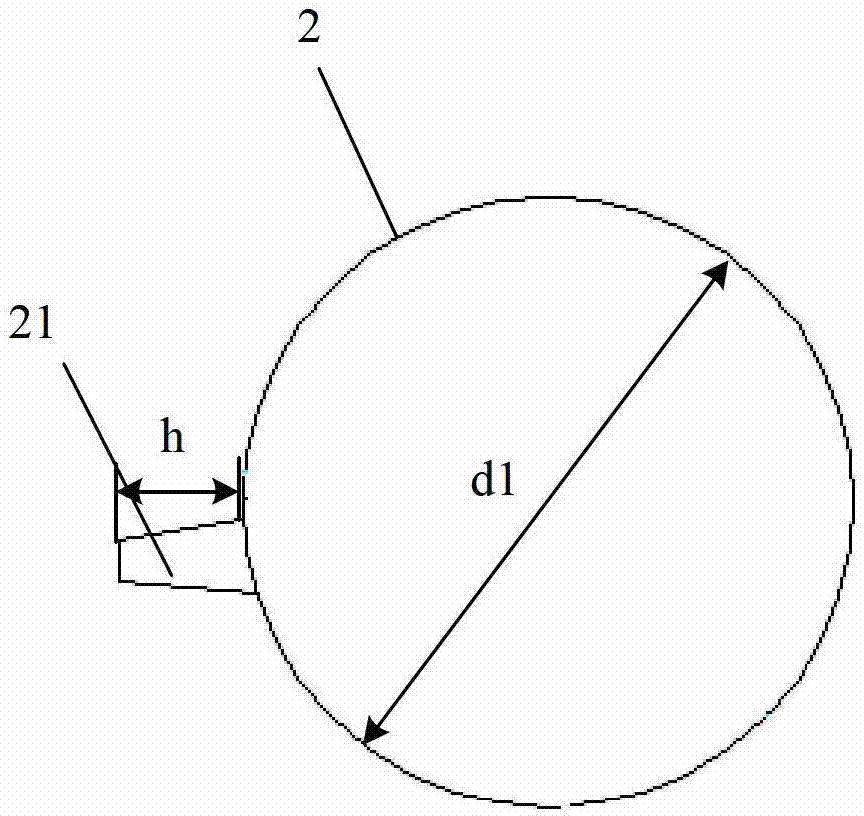

[0020] figure 1 A schematic structural diagram of a vertical continuous separation and drying device for aluminum-plastic composite packaging materials provided by an embodiment of the present invention; figure 2 for figure 1 Partial enlarged schematic diagram of A; image 3 for figure 1 Schematic enlarged cross-section of the intermediate shaft and sickle-shaped blade. The vertical continuous separation and drying device provided in this embodiment can be used for the separation treatment of aluminum-plastic composite packaging materials, and performs continuous physical separation and drying of aluminum-plastic composite packaging materials after chemical separation. Specifically, as Figure 1-Figure 3 As shown, the vertical continuous separation and drying device of this embodiment includes a vertically arranged cylinder body 1, a rotating shaft 2, a feed bin 3 and a motor 4, wherein the cylinder body 1 includes an inner cylinder body 11 and an outer cylinder body 12. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com