Carbonaceous raw material granulator

A granulator and raw material technology, which is applied in the direction of granulation in a rotating tank, can solve the problems of polluted work and outdoor environment, unstable work, and high production costs, and achieves the goal of reducing equipment maintenance costs, convenient operation and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

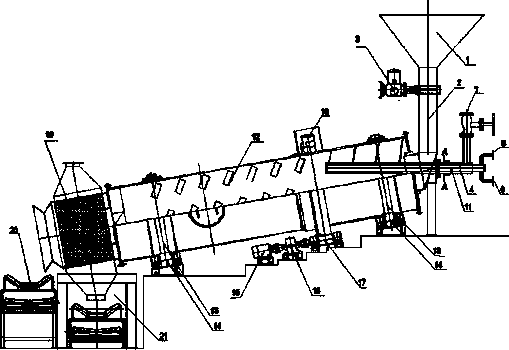

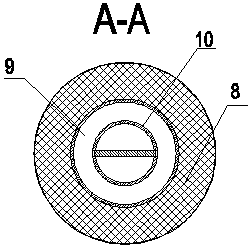

[0013] A carbonaceous raw material granulator, including a feeding mechanism, a heating mechanism, a rotary kiln rotating mechanism and a recovery mechanism, the feeding mechanism is connected to the rotary kiln rotating mechanism, and the heating mechanism is also connected to the feed port of the rotary kiln rotating mechanism The rotary kiln rotary mechanism is fixed and inclined on the base, the recovery mechanism is set at the discharge port of the rotary kiln rotary mechanism, and the feeding mechanism includes a feed bin 1, a feed pipe 2 and a feed pipe The electric actuator 3 provided on 2, the heating mechanism includes a double-layer heating pipeline 4, the heating pipeline 4 is connected to the feed inlet of the rotary kiln rotation mechanism, and the inner pipe 10 of the heating pipeline 4 The heat-conducting oil inlet 5 and the heat-conducting oil outlet 6 are respectively provided on the upper surface; the outer pipe 9 of the heating pipeline 4 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com