Technical method for separating butyraldehyde, ethanol and water mixture

A process method and mixture technology, which are applied in the fields of water mixture, separation of ternary mixed system, separation of butyraldehyde and ethanol, can solve the problems of complex separation, many by-products, troublesome separation of substances, etc., and achieve good separation effect and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

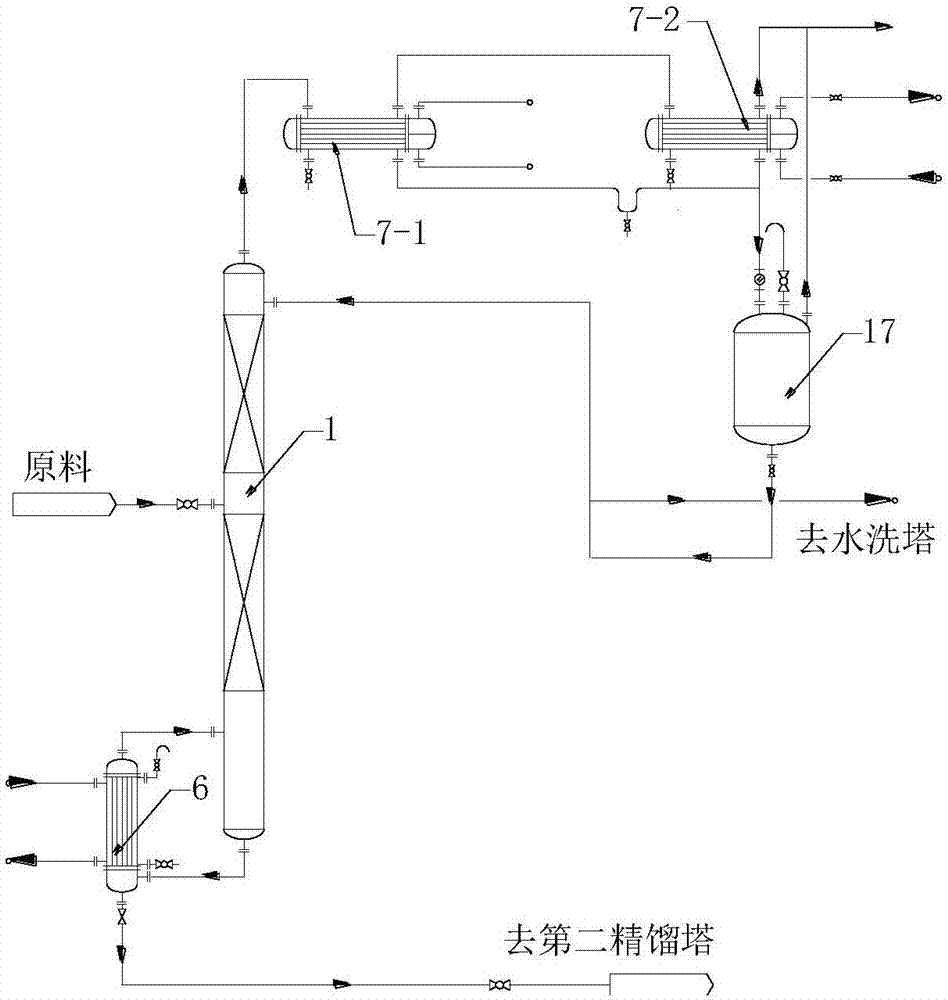

[0039] A process for separating butyraldehyde, ethanol, and water mixture, comprising a process for separating crude butyraldehyde, a process for separating ethanol, a washing process and a process for refining butyraldehyde, the steps of which are as follows:

[0040] (1) Process for separating crude butyraldehyde

[0041] Such as figure 1 As shown, the mixture raw material mainly containing ethanol, water, butyraldehyde is added to the butyraldehyde removal tower 1, then the process water extractant is added, and the material entering the butyraldehyde removal tower 1 rises to The top of the tower is condensed to a suitable temperature by the butyraldehyde removal tower primary condenser 7-1 and the butyraldehyde removal tower secondary condenser 7-2 at the top of the tower, and then enters the butyraldehyde removal tower reflux tank 17, and then flows back into the tower. The refluxed liquid and the rising steam carry out heat and mass transfer in the butyraldehyde removal...

Embodiment 2

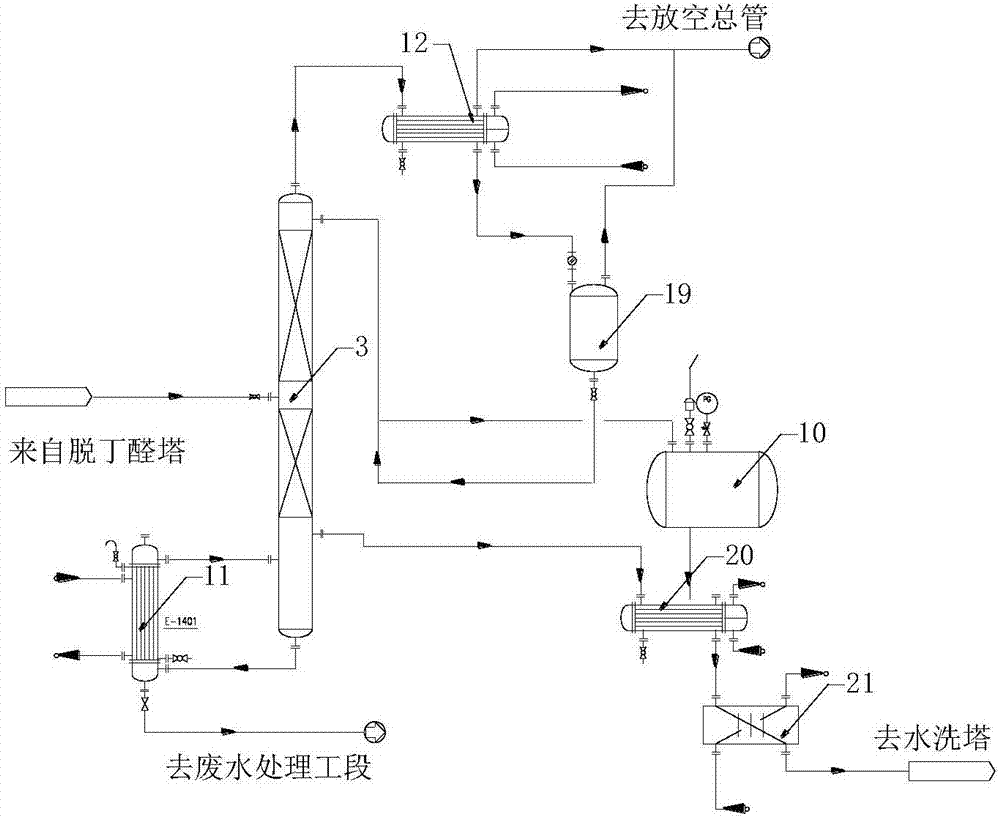

[0049] On the basis of Example 1, but different from Example 1, in the process of separating ethanol, as Figure 4-6 Shown, the butyraldehyde removal tower 1 tower kettle material enters the first rectification tower 2 after being extracted, and the first rectification tower 2 tower kettle materials rise to the tower top after the first rectification tower reboiler 8 is heated, in the tower The top is condensed into liquid by the condenser 9 of the first rectification tower, and then enters the reflux tank 18 of the first rectification tower, and then flows back into the tower. The refluxed liquid and rising steam perform heat and mass transfer in the first rectification tower 2, After the first rectification tower 2 tower top sampling analysis is qualified, then extract a part of ethanol product and go to ethanol product buffer tank 10; The material in the bottom of the rectification tower 3 rises to the top of the tower after being heated by the second rectification tower re...

Embodiment 3

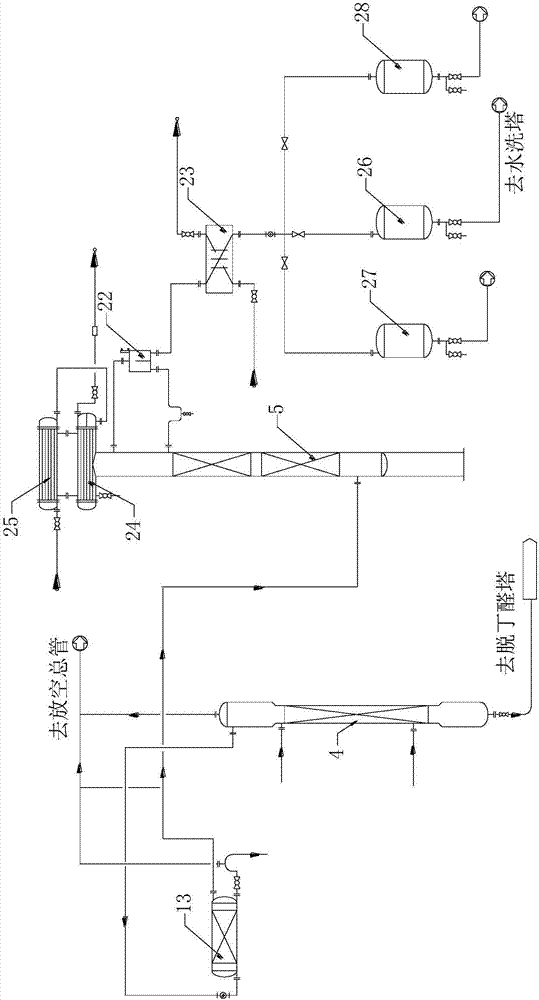

[0051] On the basis of Example 2, but different from Example 1, if the raw material contains hydrochloric acid, then the neutralization operation is carried out before the step (1), and the mixture raw material mainly containing ethanol, water, butyraldehyde After adding lye to the process water extractant for neutralization, it enters the butyraldehyde removal tower 1. Additionally, if Figure 7 As shown, the butyraldehyde removal tower 1 tower kettle is provided with the butyraldehyde removal tower coupling reboiler 14 to replace the butyraldehyde removal tower reboiler 6 in embodiment 1, and the butyraldehyde removal tower coupling reboiler 14 is also connected with The top of the first rectification tower 2, the steam at the top of the first rectification tower 2 enters the butyraldehyde removal tower coupling reboiler 14, and is condensed into liquid after heat exchange with the butyraldehyde removal tower 1 bottom material and returns to the first rectification tower Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com