Rectification type auto-cascade refrigeration system with pre-cooling function

A refrigeration system and self-cascading technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as adverse effects on refrigeration performance, large external environmental effects, unstable operation, etc., to ensure separation effect and oil removal. effect, reduce operating costs, and improve the effect of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

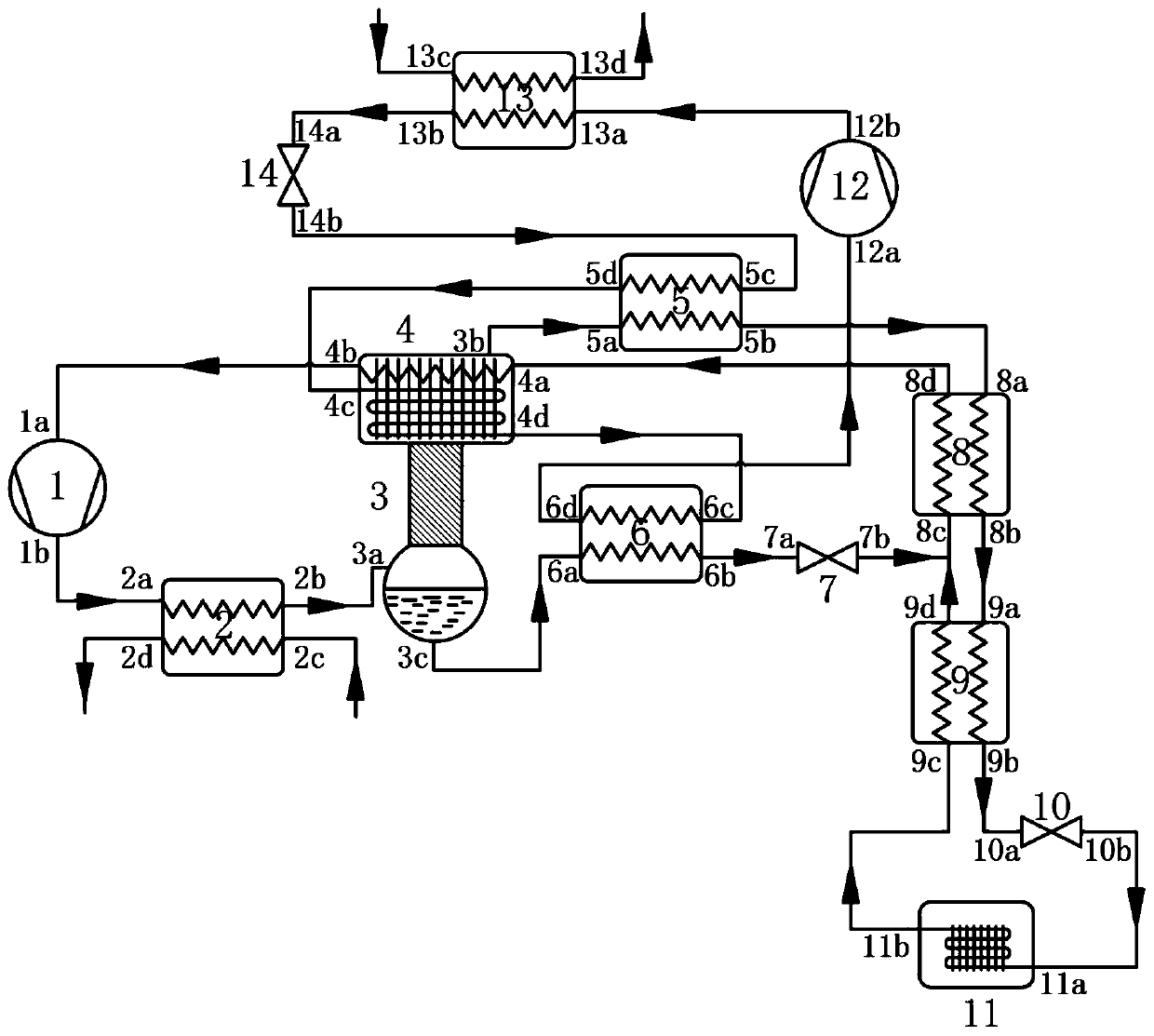

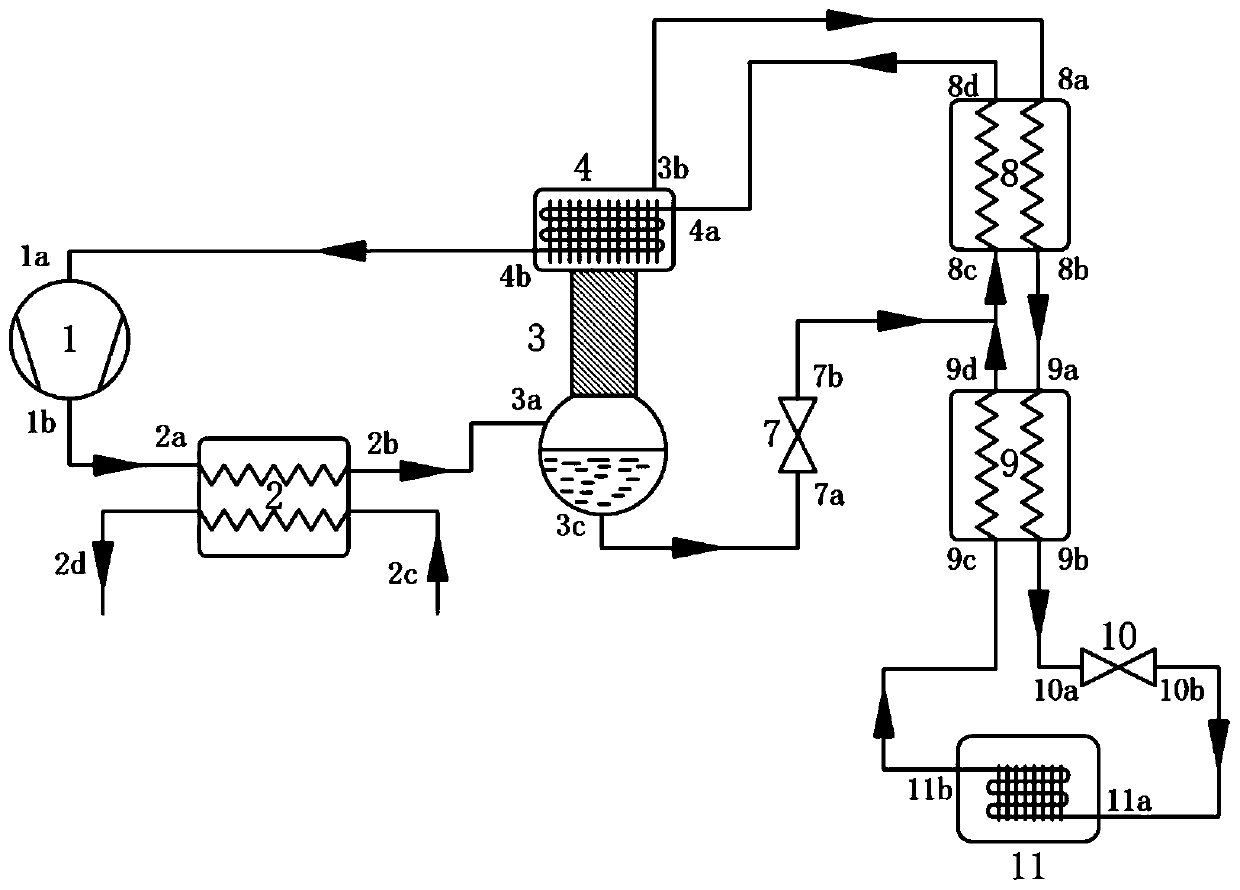

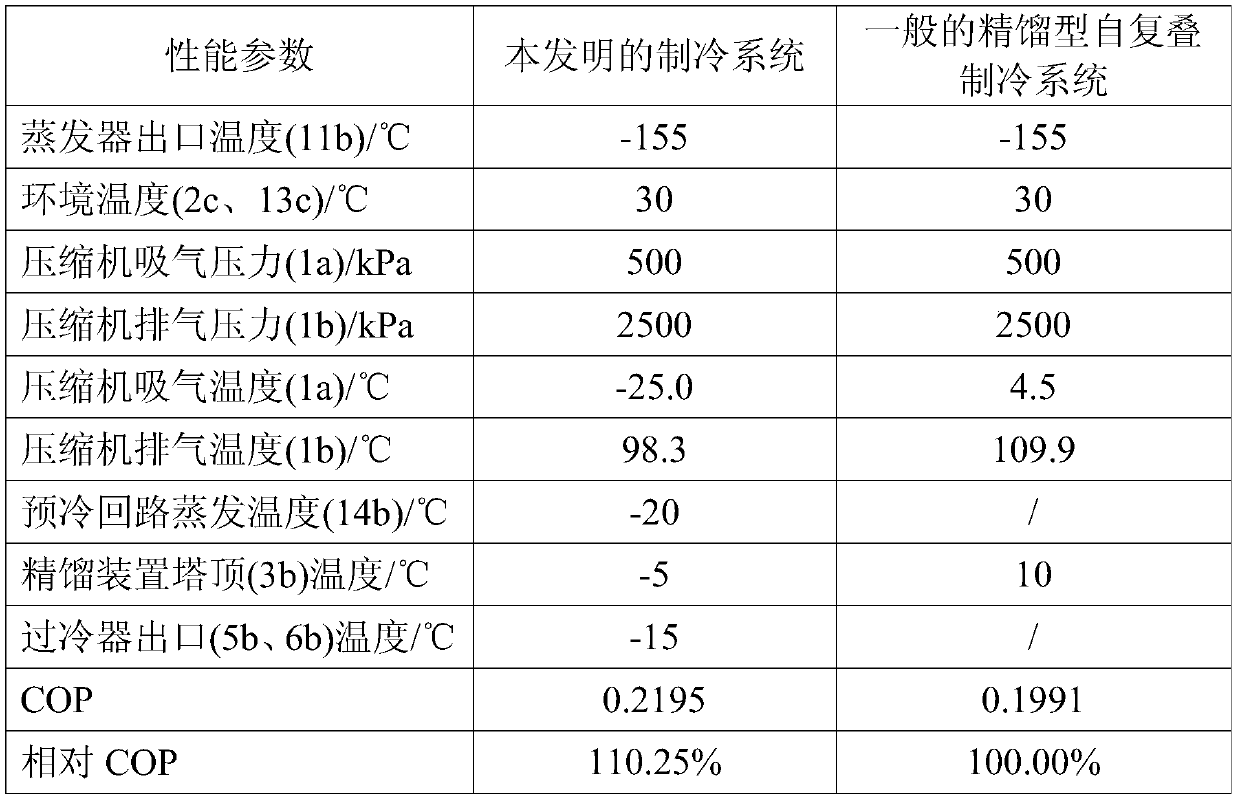

[0044] Such as figure 1 As shown, a rectification self-cascading refrigeration system with precooling includes a first compressor 12, a first condenser 13, a first throttling element 14, a second compressor 1, a second condenser 2, Rectification device 3, tower top subcooler 5, tank bottom subcooler 6, second throttling element 7, high temperature regenerator 8, low temperature regenerator 9, third throttling element 10 and evaporator 11; The distillation unit 3 comprises a tower still, a tower body and a tower top heat exchanger 4 communicating with the top of the tower body. All components form two circuits, namely a pre-cooling circuit and a rectification type self-cascading refrigeration circuit, which are integrated with a tower top heat exchanger 4, a tower top subcooler 5 and a tank bottom subcooler 6.

[0045] The tower top heat exchanger 4, the tower top subcooler 5, and the bottom subcooler 6 are equipped with first working medium pipelines; the tower top subcooler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com