Purification method for trifluoromethane

A purification method, trifluoromethane technology, applied in the field of purification of high-purity HFC, to achieve the effect of reducing workload, stable production process and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

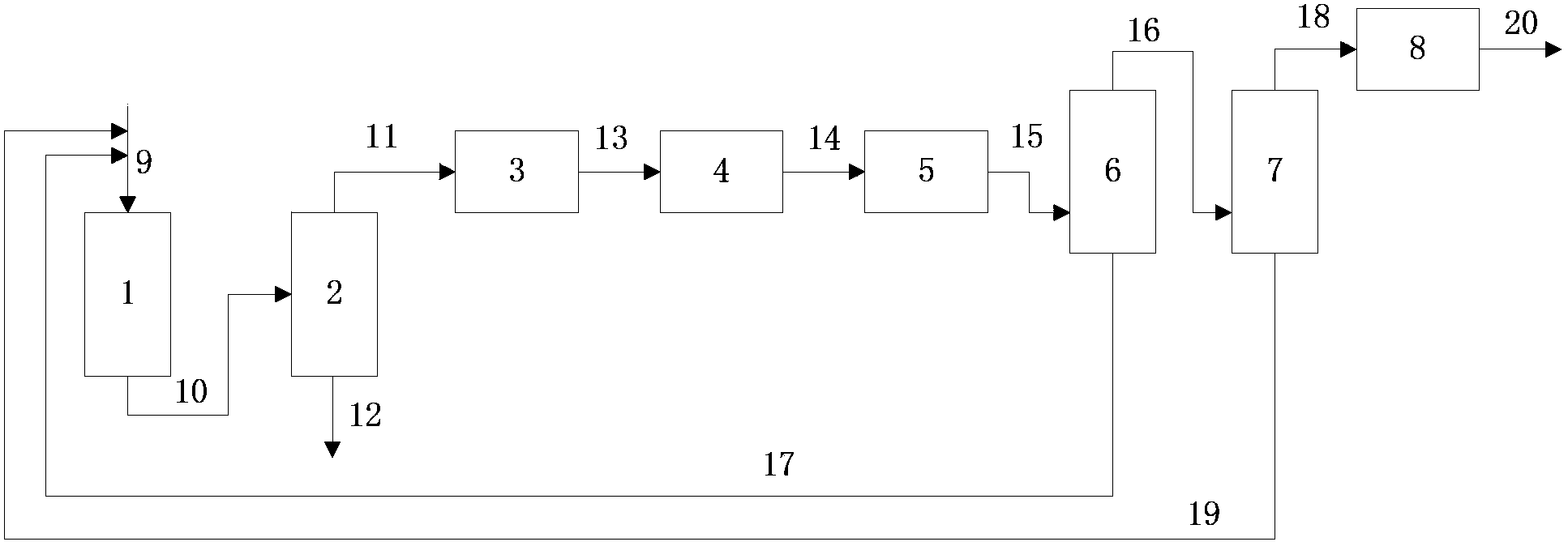

[0029] Raw materials HCFC-22 and HF are passed into the reactor (1) to react at a speed of 140Kg / h and 35Kg / h respectively, the reaction temperature is 200°C, and the pressure is 5Kpa to form a reaction product flow (10), and the reaction product flow ( 10) A stream (11) containing HFC-23, HCl, HCFC-22 and HF at a temperature of 5°C is obtained after condensation in a heat exchanger. The stream (11) is washed with water by the water washing tower (3), and 0.8Kg / h high boilers are recovered, of which about 90% are chloroform. After alkali washing and drying, a stream (15) containing HFC-23, a small amount of HCFC-22 and chloroform is obtained, wherein HFC-23 accounts for about 93% by mass of the stream (15). The stream (15) is fed from the lower body of No. 1 rectification tower (6) for rectification. The rectification temperature is controlled at about 15°C and the pressure is about 2.4MPa. The top of the tower contains HFC-23 and a small amount of HCFC-22 And the stream (16)...

Embodiment 2

[0031]Raw materials HCFC-22 and HF are passed into the reactor (1) to react at a speed of 150Kg / h and 40Kg / h respectively, the reaction temperature is 260°C, and the pressure is 9Kpa to form a reaction product flow (10), and the reaction product flow ( 10) A stream (11) containing HFC-23, HCl, HCFC-22 and HF at a temperature of 15°C is obtained after condensation in a heat exchanger. The stream (11) is washed with water by the water washing tower (3), and 0.4Kg / h high boilers are recovered, of which about 95% are chloroform. After alkali washing and drying, a stream (15) containing HFC-23 and a small amount of HCFC-22 and chloroform is obtained, wherein HFC-23 accounts for about 96% by mass of the stream (15). The stream (15) is fed from the lower body of the No. 1 rectification tower (6) for rectification. The rectification temperature is controlled at about 7°C and the pressure is about 2.2MPa. The top of the tower contains HFC-23 and a small amount of HCFC-22. And the stre...

Embodiment 3

[0033] The raw materials HCFC-22 and HF are passed into the reactor (1) at a speed of 170Kg / h and 50Kg / h respectively for reaction, the reaction temperature is 350°C, and the pressure is 15Kpa to form a reaction product flow (10), and the reaction product flow ( 10) A stream (11) containing HFC-23, HCl, HCFC-22 and HF at a temperature of 25°C is obtained after condensation in a heat exchanger. The stream (11) is washed with water by the water washing tower (3), and 0.4Kg / h high boilers are recovered, of which about 92% are chloroform. After alkali washing and drying, a stream (15) containing HFC-23, a small amount of HCFC-22 and chloroform is obtained, wherein HFC-23 accounts for about 98% by mass of the stream (15). The stream (15) is fed from the lower body of the No. 1 rectification tower (6) for rectification. The rectification temperature is controlled at about 3°C and the pressure is about 1.9MPa. The top of the tower contains HFC-23 and a small amount of HCFC-22. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com