Process and device for purifying and recovering acetic acid waste liquid

An acetic acid and waste liquid technology, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of large floor space, complicated process flow, inability to directly obtain acetic acid, etc., and achieve the effect of reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

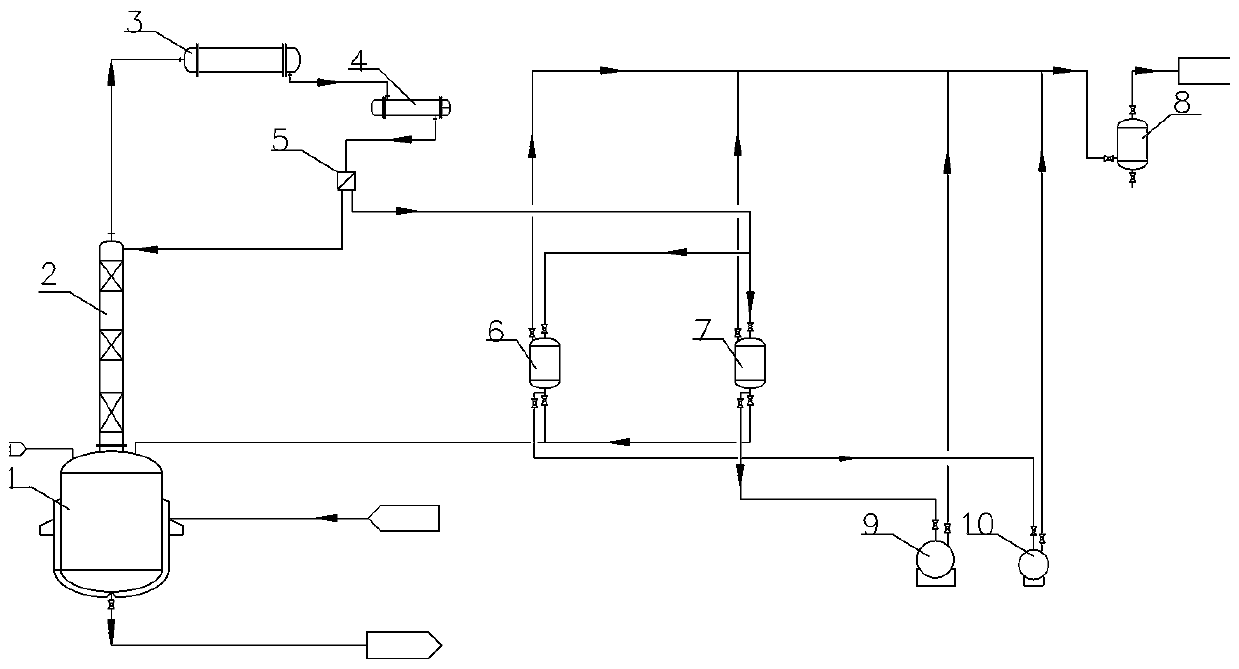

[0026] A high-purity acetic acid rectification device. The acetic acid rectification tower 1 is connected to the rectification vessel 2, the rectification vessel 2 is connected to the top-level condenser 3, the top-level condenser 3 and the top-level secondary condenser 4 Connected, the top secondary condenser 4 is connected to the reflux ratio controller 5, the reflux ratio controller 5 is connected to the rectification vessel 2, the reflux ratio controller 5 is connected to the acetic acid waiting tank 7, the acetic acid waiting tank 7 and the acetic acid product tank 9Connect.

[0027] The acetic acid waiting tank 7 is connected to the front fraction tank 6. The bottom part of the front fraction tank 6 is connected to two paths, one is connected to the intermediate tank 10, and the other is connected to the acetic acid rectification tower 1.

[0028] The bottom of the acetic acid waiting tank 7 is connected to the acetic acid rectifying tower 1.

[0029] The top of the front frac...

Embodiment 2

[0031] The process performed by the above device is:

[0032] 1. Check whether the equipment, pipelines, and valves are in good condition, whether the opening and closing positions are in the correct position, and adjust the valves to normal working conditions.

[0033] 2. Open the material inlet valve of the distillation kettle, turn on the feed pump, and pump materials into the distillation kettle. Control the liquid level of the distillation kettle. At this time, the feed dilute acetic acid solution is about 2.6m3. The analysis and detection of the feed material acetic acid concentration is 78%, and the feed pump is closed according to the normal operation steps, and the inlet valve is closed.

[0034] 3. Start to feed in 0.8MPa saturated steam, control the steam flow to 190 kg / h, and open the steam condensate outlet valve of the jacket of the rectification kettle. The opening and closing degree of the low-pressure steam control valve should be adjusted slowly from small to large...

Embodiment 3

[0041] The specific process operation is shown in Example 2. The feed dilute acetic acid solution is 2.4m3, the concentration is 81%, the steam flow rate is 205 kg / h, the rectification tower kettle operation is 121 ℃, the tower top operation temperature is 99 ℃, and the tower kettle operation pressure is 105KPa , The operating pressure at the top of the tower is 101 KPa, the top temperature of the front fraction is 110°C, the temperature of the top of the acetic acid fraction is 117°C, the reflux ratio of the front fraction is 4:1, and the reflux ratio of the acetic acid fraction is 3:1; the purity of 98.7% is obtained. Acetic acid products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com