Method for recovering dichloromethane

A dichloromethane and recovery method technology, which is applied in the field of recovery and application of chemical synthesis solvents, can solve problems such as high water content, inability to be directly applied, troublesome operation, etc., and achieve the effect of obvious rectification effect and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Firstly: add ethylene glycol to dichloromethane; secondly: put the mixture of dichloromethane and ethylene glycol into a rectification tower; finally: separate and purify the water of the dichloromethane to 0.5% through a rectification tower Below; Described ethylene glycol adopts direct addition method to join in the dichloromethane when adding.

[0014] Take 300ml of dichloromethane with a water content of 1.1%, add 5ml of ethylene glycol, rectify at atmospheric pressure (tower height 100mm), collect 39-41 degree fractions, collect a total of 240ml fractions, and have a moisture content of about 0.5%.

[0015] Be the experimental data of embodiment 1 below:

[0016] serial number Aqueous dichloromethane (ml) Amount of ethylene glycol (g) Fraction (ml) Moisture (%) 1 300 12 240 0.55 2 300 18 238 0.65 3 300 24 236 0.55 4 300 30 237 0.55

Embodiment 2

[0018] First: put dichloromethane into the rectifying tower; secondly: add ethylene glycol into the dichloromethane through the addition port of the rectifying tower, and finally: separate and purify the water of the dichloromethane through the rectifying tower to Below 0.5%; Described ethylene glycol adopts dropwise method to join in the dichloromethane when adding.

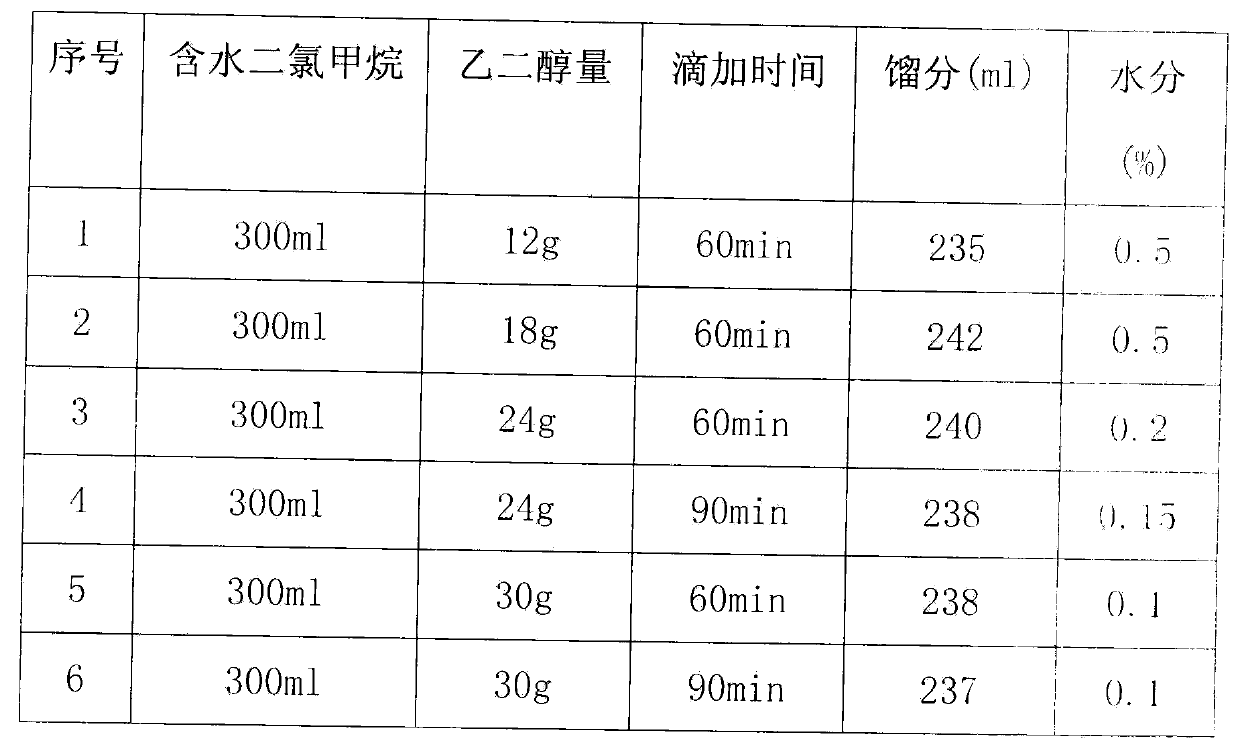

[0019] Be the experimental data of embodiment 2 below:

[0020]

[0021] The above data has been verified many times in the experiment, and the results show that ethylene glycol can achieve a good fractionation effect by fully exchanging gas-liquid through dripping, and the recovered water of dichloromethane can basically be controlled below 0.15%. The ethylene glycol can also be recycled.

[0022] The recovery method of dichloromethane of the present invention solves the difficult problem that dichloromethane and water can azeotrope in the prior art, even if a rectification tower is used, the moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com