Air separation device for large liquid amount preparation and method

An air separation plant and liquid volume technology, which can be used in liquefaction, cold treatment separation, refrigeration and liquefaction, etc., and can solve problems such as increasing energy consumption of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated and illustrated below in conjunction with specific embodiments and accompanying drawings.

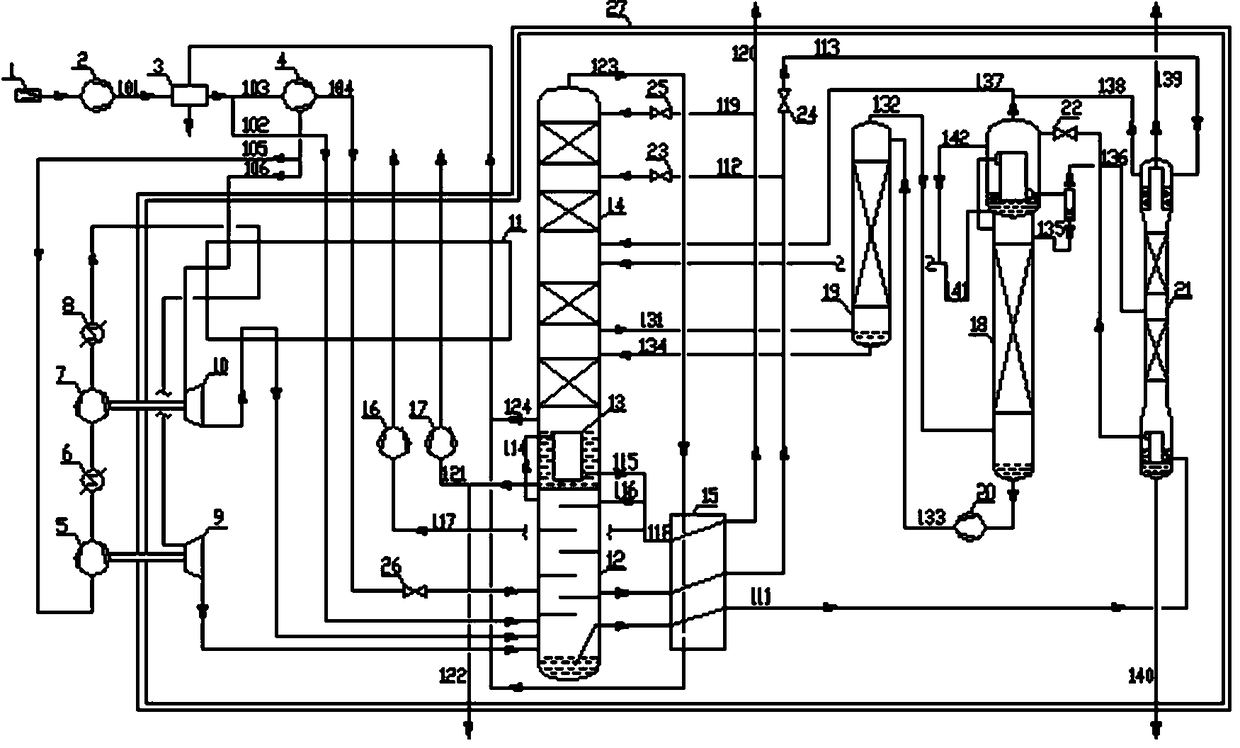

[0024] Such as figure 1 As shown, an air separation plant for producing a large amount of liquid includes an air filter 1, an air compressor 2, an air purification unit 3, an air booster 4, a supercharging end 5 of a cryogenic machine and an expansion end 9 of a low temperature expander , the supercharged end cooler 6 of the low temperature machine, the supercharged end 7 of the high temperature machine and the expansion end 10 of the high temperature expander, the supercharged end cooler 8 of the high temperature machine and the cryogenic separation cold box unit 27, the cryogenic separation cold box unit 27 Including main heat exchanger 11, lower tower 12, condensing evaporator 13, upper tower 14, subcooler 15, liquid nitrogen pump 16, liquid oxygen pump 17, crude argon tower I18, crude argon tower II19, circulating liquid argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com