Dehydrating tower for recycling NMP waste liquid

A waste liquid recovery and dehydration tower technology, applied in the direction of fractionation, can solve the problems of insufficient NMP purity and low efficiency, and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

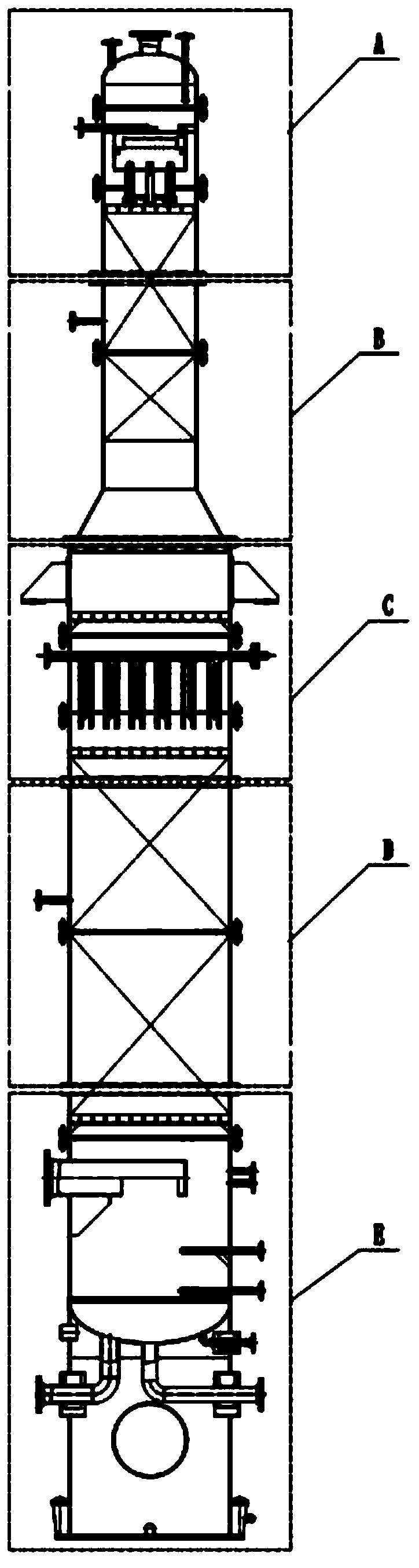

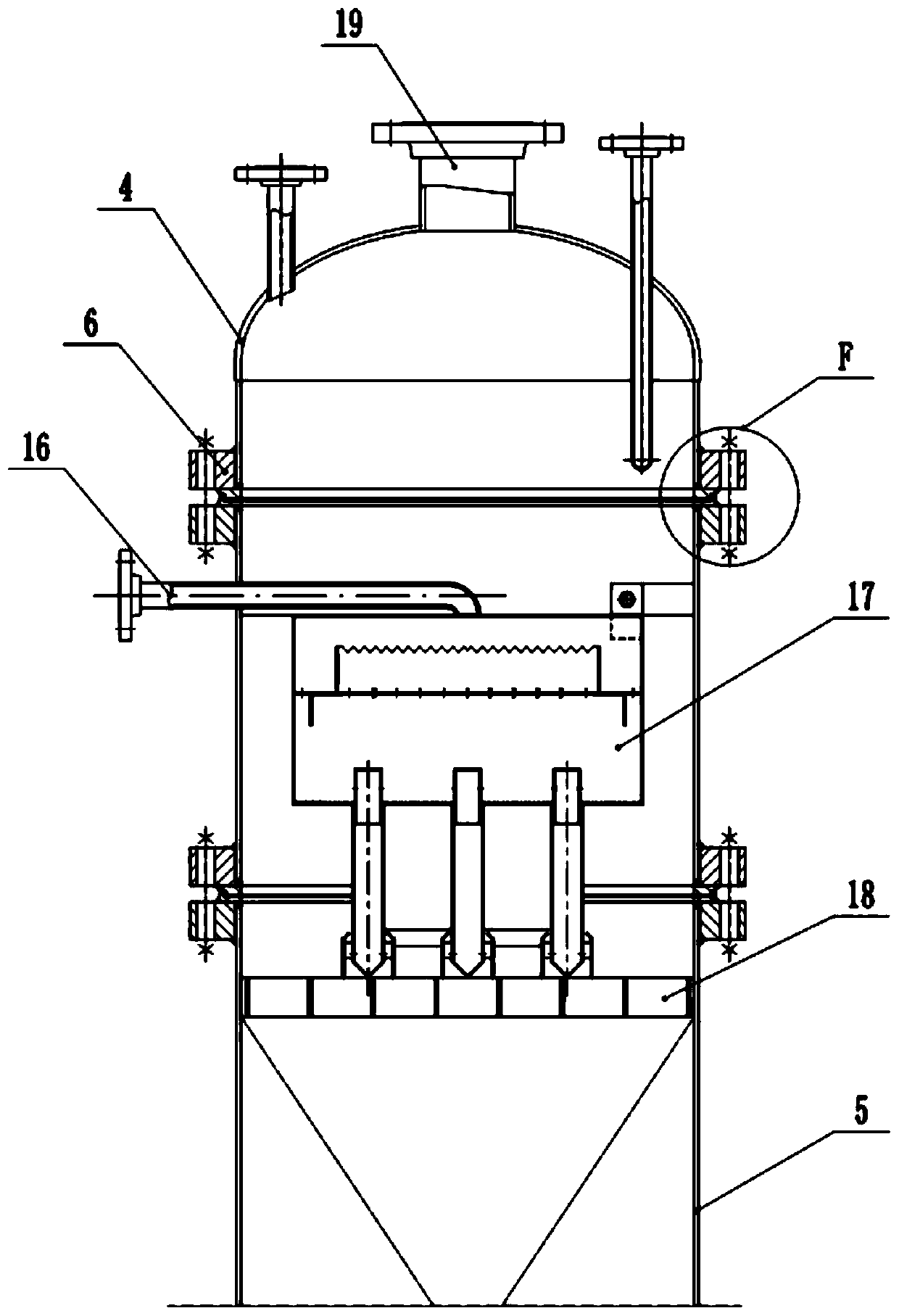

[0039] Embodiment 1 is basically as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown:

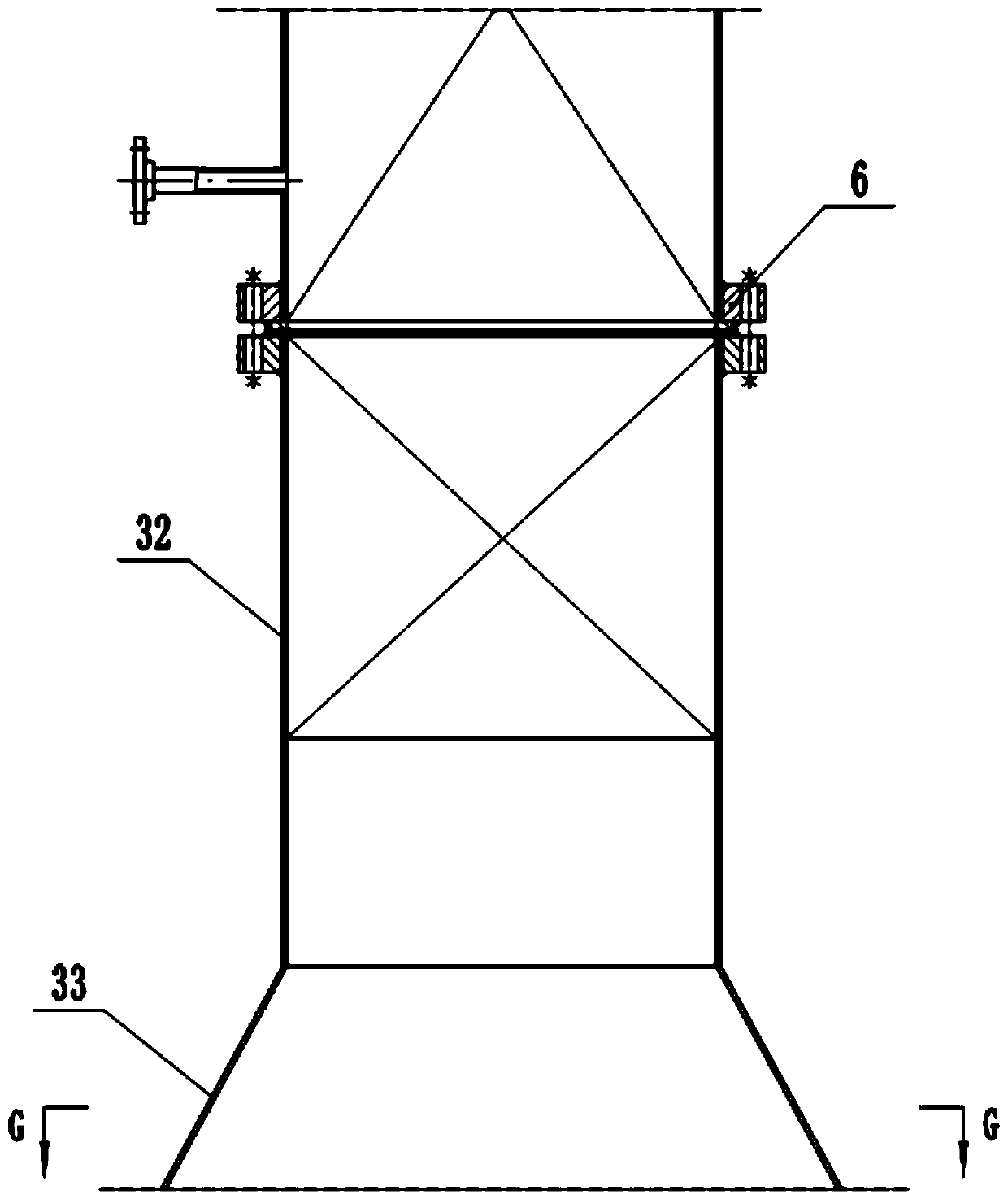

[0040] A dehydration tower for NMP waste liquid recovery, comprising a tower base 1, a tower kettle 2, a tower body 3 and a tower top 4 fixedly connected sequentially from bottom to top, wherein the tower base 1 is fixed on the ground by bolts, and the tower body 3 includes a lift Distillation section 31 and rectification section 32, wherein rectification section 32 is positioned at the top of stripping section 31, and the diameter of rectification section 32 is 0.65~0.7 times of the diameter of stripping section 31, and the diameter of stripping section 31 in the present embodiment The diameter of the rectifying section 32 is 0.7m. The stripping section 31 and the rectifying section 32 are connected with a conical section 33 with a narrow top and a wide bottom. The tower body 3 is formed by detachable connection of multiple cylinders 5 , that is, t...

Embodiment 2

[0048] Embodiment 2 is basically as attached Figure 8 Shown:

[0049] The difference from Embodiment 1 is that a flow guide structure is also provided on the inner wall of the tapered section 33, specifically, a plurality of flow guide bars 22 are vertically fixed on the inner wall of the tapered section 33, and a plurality of flow guide bars The strips 22 are uniformly distributed along the circumference of the tapered section 33 , and flow guide grooves 23 are formed between adjacent flow guide bars 22 . The formation of a plurality of diversion grooves 23 makes it possible for the liquid beads that may condense on the inner wall of the conical section 33 to flow down along the diversion grooves 23 during the working process of the dehydration tower, and then enter the stripping section 31 again and be absorbed by the high-temperature steam. It is vaporized under the action, and then the rectification is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com