Oxygen generator

An oxygen generator and liquid oxygen technology, applied in the field of oxygen generators, can solve the problems of wasting power consumption and no recovery of cooling capacity, and achieve the effects of saving energy, reducing electricity consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The object of the present invention is to provide an oxygen generator capable of recovering the cooling capacity of low-temperature liquid products, which can recover the cooling capacity of liquids while meeting the demand for gas products of users.

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the utility model will be further described in detail below with reference to the accompanying drawings and examples.

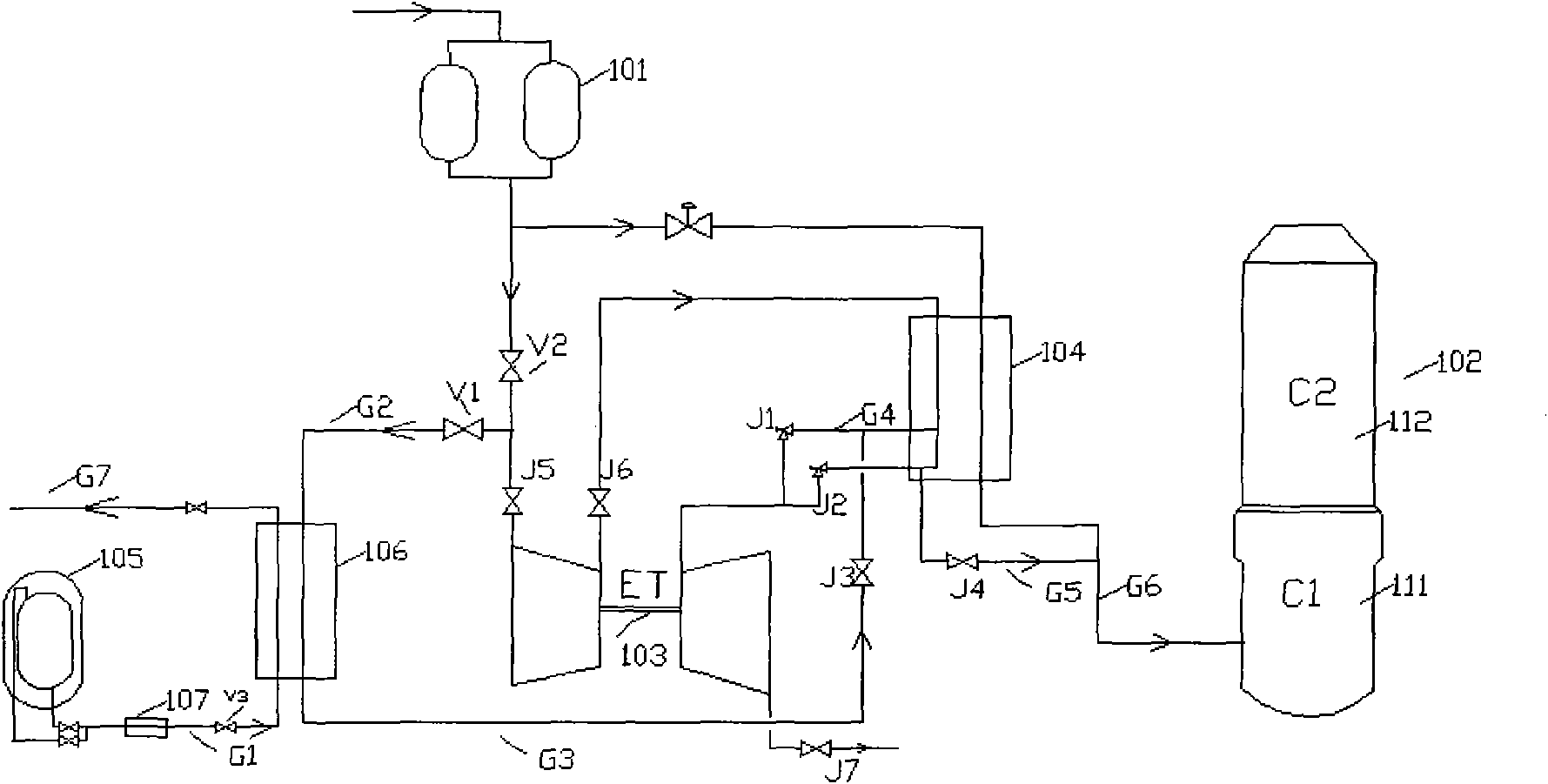

[0025] figure 1 It is a structural schematic diagram of the first embodiment of the oxygen generator of the present invention. Such as figure 1 As shown, the oxygen generator of the present invention includes a molecular sieve purifier 101 , a main tower 102 , an expander 103 , a mainboard heat exchanger 104 , a liquid oxygen or liquid nitrogen storage tank 105 and a high-pressure heat exchanger 106 . When the high-pressure heat exchanger 106 is working, the expander 103 in the process of producing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com