Liquid distillation device

A distillation device and liquid technology, applied in mixers with rotary stirring devices, fractionation, transportation and packaging, etc., can solve the problems of prolonging the distillation time, poor stirring strength, and affecting the distillation effect, so as to improve the stirring efficiency, The effect of enhancing the effect and accelerating the distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

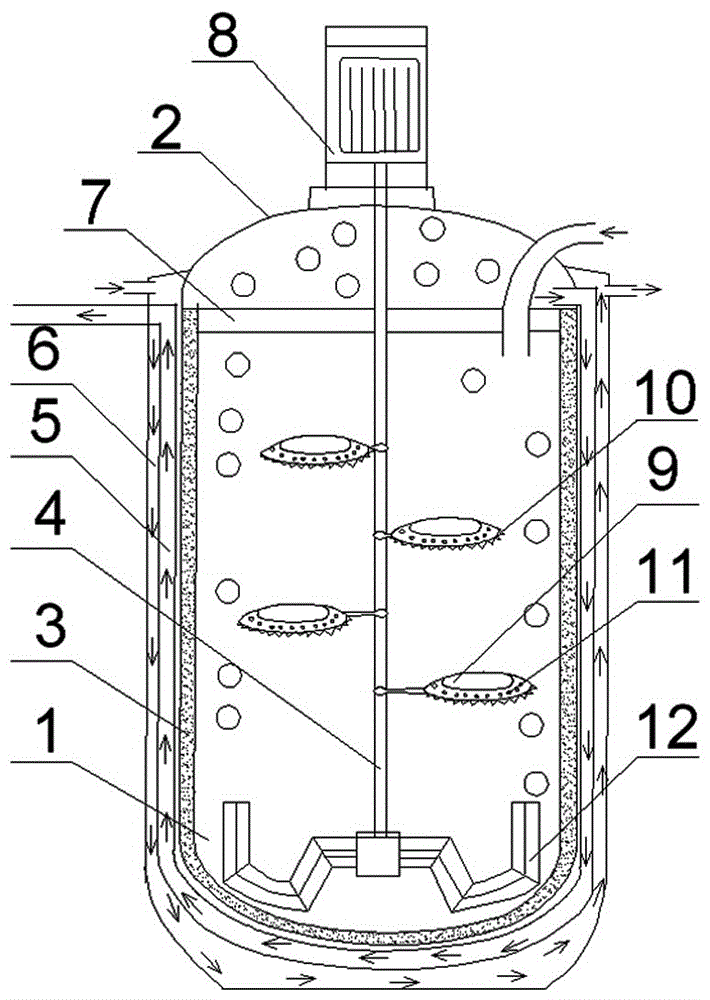

[0025] The main structure of this embodiment, such as figure 1 Shown: includes a tank body 1, the bottom of the tank body 1 is equipped with a discharge port, the top of the tank body 1 is connected with an upper cover 2, and the upper cover 2 is provided with a feed port, the tank body 1 and the upper cover A distillation cavity is formed between 2, a stirring tool is installed in the center of the distillation cavity, the stirring tool is connected with a motor 8, the stirring tool mainly includes a rotating shaft 4, and a stirring plate 12 is installed at the bottom of the rotating shaft 4, The middle part of the rotating shaft 4 is provided with a plurality of clamps, the distance between the multiple clamps is equal, the stirring plate 9 is installed on the clamps, and the outside of the tank body 1 is provided with a condensation device, and the condensation device includes a steam pipe 5 And the condensation channel 6, the steam pipe 5 communicates with the inside of th...

Embodiment approach

[0026] Concrete embodiment: the liquid distillation device mainly includes a tank body 1 and an upper cover 2, and a feed inlet is installed on one side of the upper cover 2, and the liquid to be distilled enters from the feed inlet, and the bottom of the tank body 1 is provided with Outlet, the distilled liquid is discharged from the outlet, the upper cover 2 is also provided with an outlet for steam overflow, a distillation cavity is formed between the tank body 1 and the upper cover 2, in order to prevent the distillation The substance is sticky to the tank body 1 and to improve the distillation effect. A stirring tool is arranged inside the distillation cavity. The stirring tool mainly includes a rotating shaft 4, which is connected to a motor 8. In order to provide better power, the motor 8 can be installed on the upper seal On the top of the cover 2, a stirring piece 12 is symmetrically arranged at the bottom of the rotating shaft 4. The shape of the stirring piece 12 is ...

Embodiment 2

[0030] This embodiment further defines the clamps on the basis of Embodiment 1. The plurality of clamps are arranged in a staggered manner. The shape of the stirring plate 9 is gradually reduced from the bottom to the upper outer edge to the center. A plurality of sawtooth 10 is installed on the top, and the size of the sawtooth 10 is different. A plurality of sawtooth 10 is installed on the outermost edge of the stirring plate 9. The size of the sawtooth 10 is different. Between the tank body 1 and the upper cover 2 Hydrophobic gas-permeable membrane 7 is also installed.

[0031] The specific implementation mode by increasing the above-mentioned technical features is: in order to further optimize the stirring tool, the shape of the stirring plate 9 is set to gradually decrease from the bottom to the upper outer edge to the center, forming a relative circular platform, and at the same time, there are A plurality of small round holes 11, the small round holes 11 can make the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com