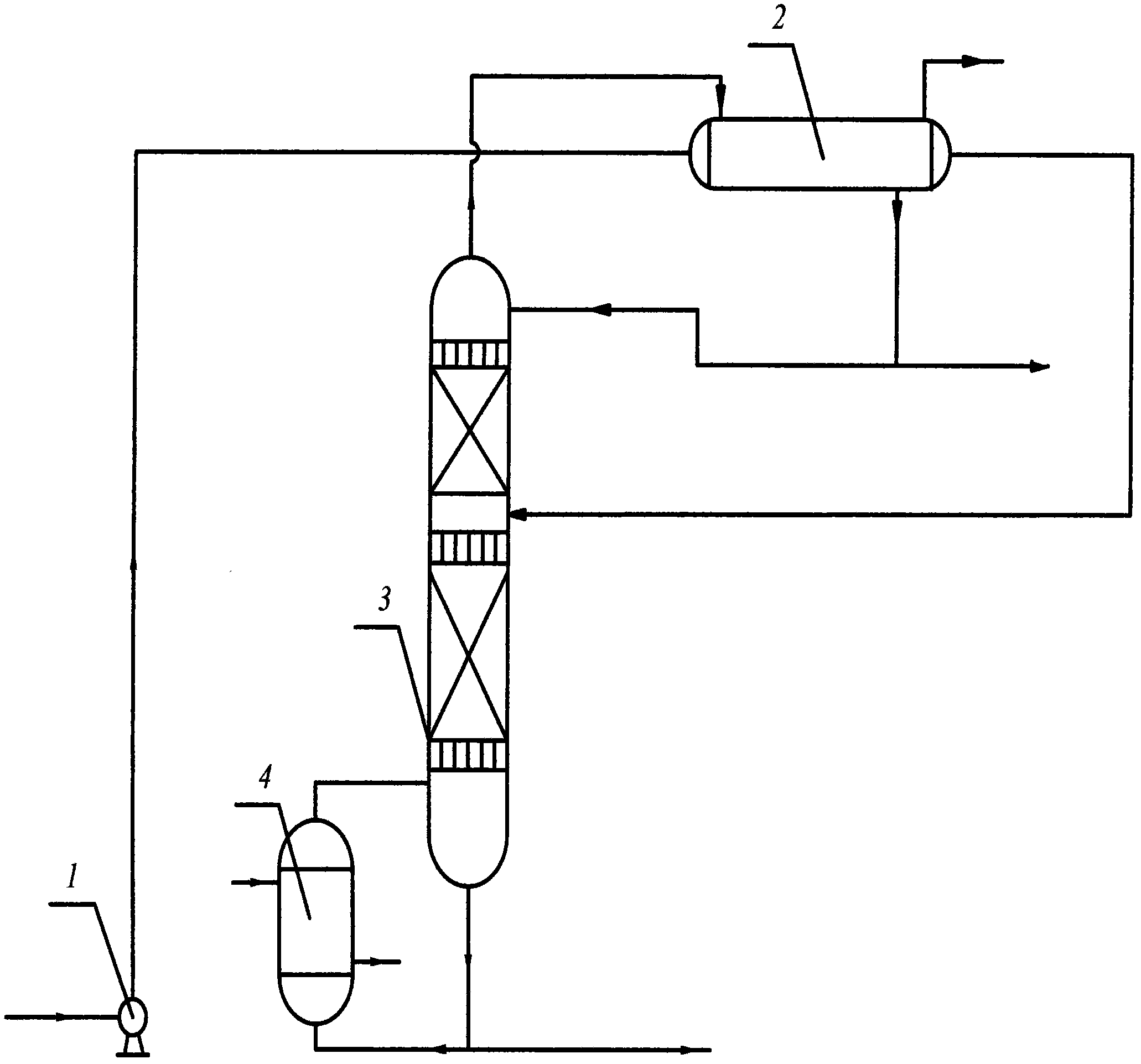

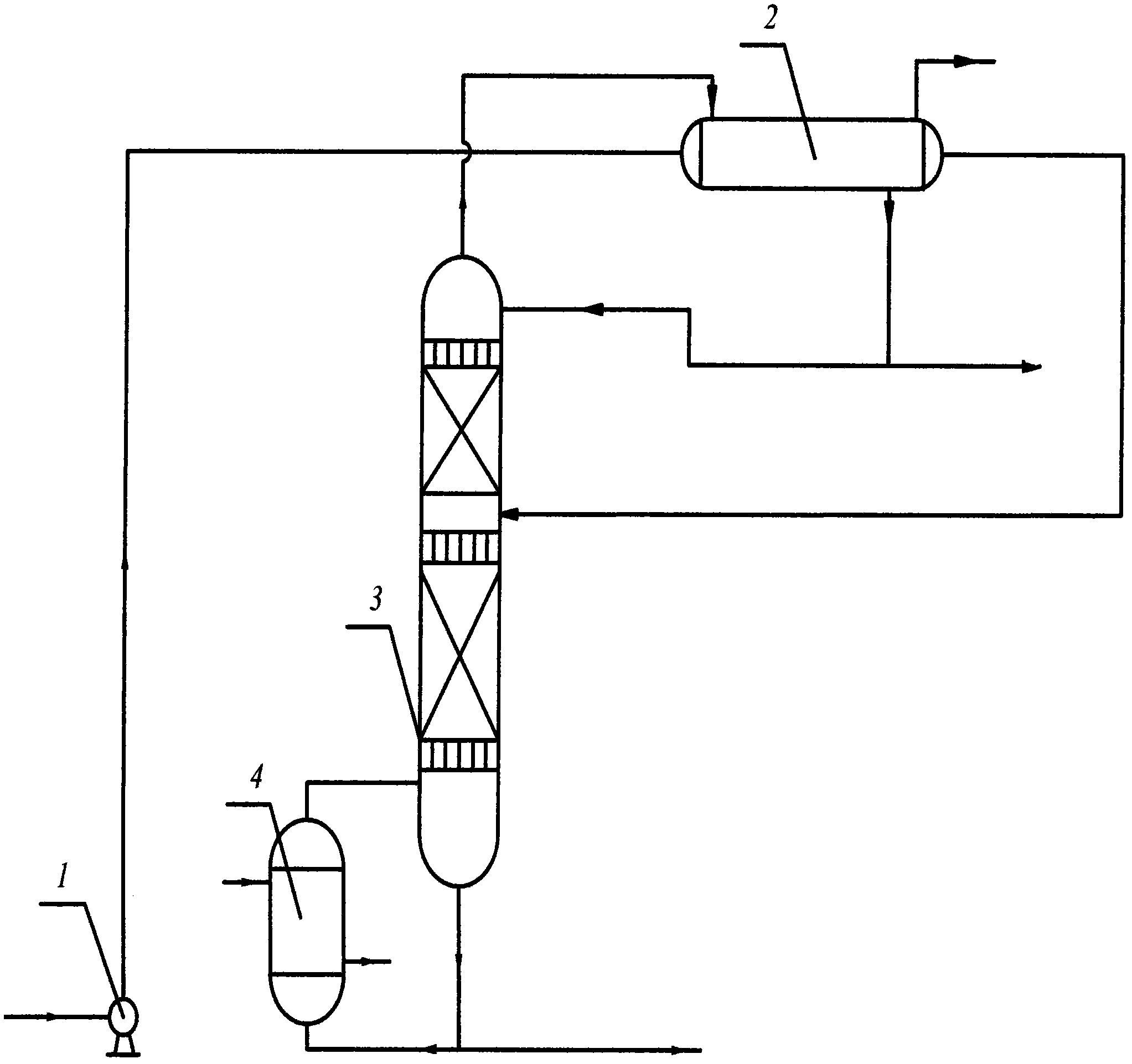

Method for producing high-purity optical isoamylol through decompression and rectification and technical process thereof

A vacuum distillation, isoamyl alcohol technology, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problems of low separation efficiency, complex process, high processing cost, and improve the purity and effect. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Implementation Example 1: The optical isoamyl alcohol accounts for 10.42% in the raw material mixed isoamyl alcohol, and the isoamyl alcohol accounts for 89.53%. The other contents are impurities, and the temperature is 20°C. Carry out rectification under vacuum in the described rectification under vacuum according to the steps described above, the operating pressure of rectification under vacuum is an optimal pressure after optimization in the scope of 0.05-0.5atm, and the reflux ratio is 20:1, preheated to 60°C before entering the tower, the feed position is at 6 / 10 of the tower, the residence time of the raw material in the top condenser is 5s, and the residence time of the material in the vacuum distillation tower is 20s, The recovery percentage at the bottom of the tower is 25%, and the quality of the obtained product has an optical purity of isoamyl alcohol of 99.95%, and a purity of isoamyl alcohol of 99.98%.

Embodiment 2

[0046] Implementation example 2: The optical isoamyl alcohol accounts for 19.30% in the raw material mixed isoamyl alcohol, and the isoamyl alcohol accounts for 80.62%. The other contents are impurities, and the temperature is 20°C. Carry out rectification under vacuum in the described rectification under vacuum according to the steps described above, the operating pressure of rectification under vacuum is an optimal pressure after optimization in the scope of 0.05-0.5atm, and the reflux ratio is 18:1, preheated to 60°C before entering the tower, the feed position is at 6 / 10 of the tower, the residence time of the raw material in the top condenser is 5s, and the residence time of the material in the vacuum distillation tower is 22s, The recovery percentage at the bottom of the tower is 28%, and the quality of the product obtained has an optical purity of isoamyl alcohol of 99.96%, and a purity of isoamyl alcohol of 99.97%.

Embodiment 3

[0047] Implementation example 3: The optical isoamyl alcohol accounts for 30.11% in the raw material mixed isoamyl alcohol, and the isoamyl alcohol accounts for 69.85%. The other contents are impurities, and the temperature is 20°C. Carry out rectification under vacuum in the described rectification under vacuum according to the steps described above, the operating pressure of rectification under vacuum is an optimal pressure after optimization in the scope of 0.05-0.5atm, and the reflux ratio is 18:1, preheated to 65°C before entering the tower, the feed position is at 6 / 10 of the tower, the residence time of the raw material in the top condenser is 5s, and the residence time of the material in the vacuum distillation tower is 22s, The recovery percentage at the bottom of the tower is 30%, the quality of the obtained product is optical isoamyl alcohol purity 99.97%, and the purity of isoamyl alcohol is 99.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com