Preparation method of high-purity p-methyl benzyl alcohol

A p-methylbenzyl alcohol, high-purity technology, applied in the field of preparation of high-purity p-methylbenzyl alcohol, can solve the problems of endangering the health of operators, difficult recycling, and polluting the production environment, so as to reduce energy consumption and cost, avoid Post-processing burden and the effect of reducing environmental emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

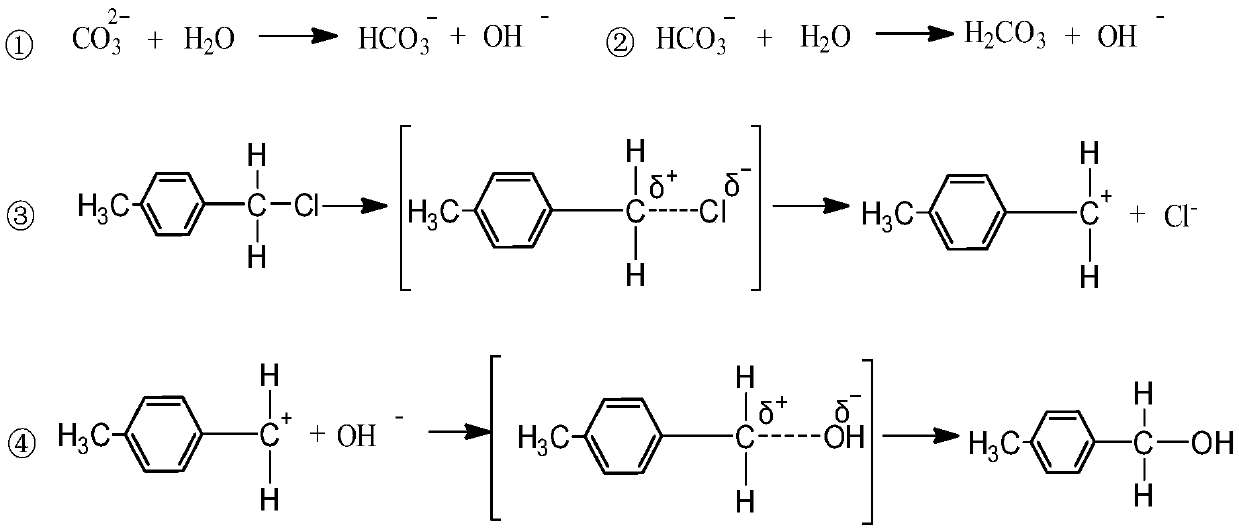

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for high-purity p-methylbenzyl alcohol, comprising the following steps:

[0030] 1) Add 4000kg of pure water and 400kg of sodium carbonate to the reaction kettle, stir and heat to 50°C, then add 800kg of p-methylbenzyl chloride to the mixture, and check the initial pH value to be 8.7. Continue to heat up to 115°C, and increase the pressure of the batching tank to 0.15MPa. Take a sample after reacting for 5 hours, the pH test shows that the pH value is 7.8, the GC test shows that the content of p-methylbenzyl alcohol is 98.8%, the content of p-methylbenzyl chloride is 0.01%, and the content of di-p-methylbenzyl ether is 0.87%, stop the reaction .

[0031] Separate the liquid, collect the organic phase, and obtain 691.6 kg of crude p-methylbenzyl alcohol.

[0032] 2) Repeatedly evacuate and fill the rectification system with nitrogen until the oxygen content is lower than 0.5%, and press the crude p-methylbenzyl alcohol into the rectification kettle...

Embodiment 2

[0035] A preparation method for high-purity p-methylbenzyl alcohol, comprising the following steps:

[0036] 1) Add 4000kg of pure water and 400kg of sodium carbonate to the reaction kettle, stir and heat to 55°C, then add 800kg of p-methylbenzyl chloride to the mixture, and check the initial pH value to be 8.9. Continue to heat up to 115°C, and increase the pressure of the batching tank to 0.16MPa. After reacting for 5 hours, the sample was taken, and the pH test showed that the pH value was 7.9. The GC test showed that the content of p-methylbenzyl alcohol was 98.6%, the content of p-methylbenzyl chloride was 0.02%, and the content of di-p-methylbenzyl ether was 0.94%. Stop the reaction .

[0037] Separate the liquid, collect the organic phase, and obtain 695.6 kg of crude p-methylbenzyl alcohol.

[0038] 2) Repeatedly evacuate and fill the rectification system with nitrogen until the oxygen content is lower than 0.5%, and press the crude p-methylbenzyl alcohol into the re...

Embodiment 3

[0041] A preparation method for high-purity p-methylbenzyl alcohol, comprising the following steps:

[0042]1) Add 4000kg of pure water and 400kg of sodium carbonate to the reaction kettle, stir and heat to 60°C, then add 800kg of p-methylbenzyl chloride to the mixture, and check the initial pH value to be 8.8. Continue to heat up to 114°C, and increase the pressure of the batching tank to 0.15MPa. After reacting for 5 hours, take a sample, the pH detection shows that the pH value is 7.6, the GC detection shows that the content of p-methylbenzyl alcohol is 98.8%, the content of p-methylbenzyl chloride is 0.02%, and the content of di-p-methylbenzyl ether is 0.95%, stop the reaction .

[0043] Separate the liquid, collect the organic phase, and obtain 699.2kg of crude p-methylbenzyl alcohol.

[0044] 2) Repeatedly evacuate and fill the rectification system with nitrogen until the oxygen content is lower than 0.5%, and press the crude p-methylbenzyl alcohol into the rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com