Disc type overload protection anti-impact speed reducer

An overload protection and anti-shock technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve problems such as hidden dangers of service life, inability to effectively protect the internal structure, affecting service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the accompanying drawings and embodiments.

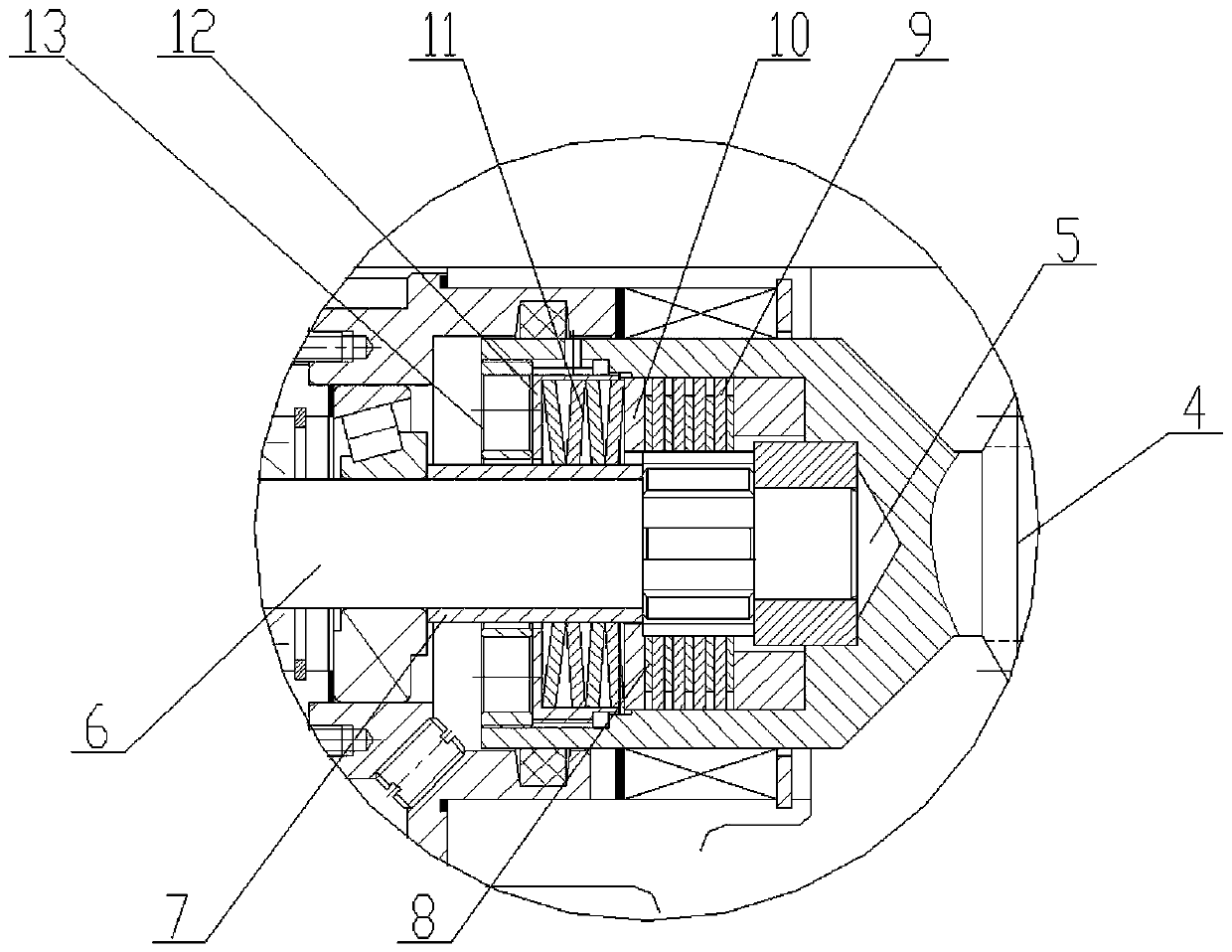

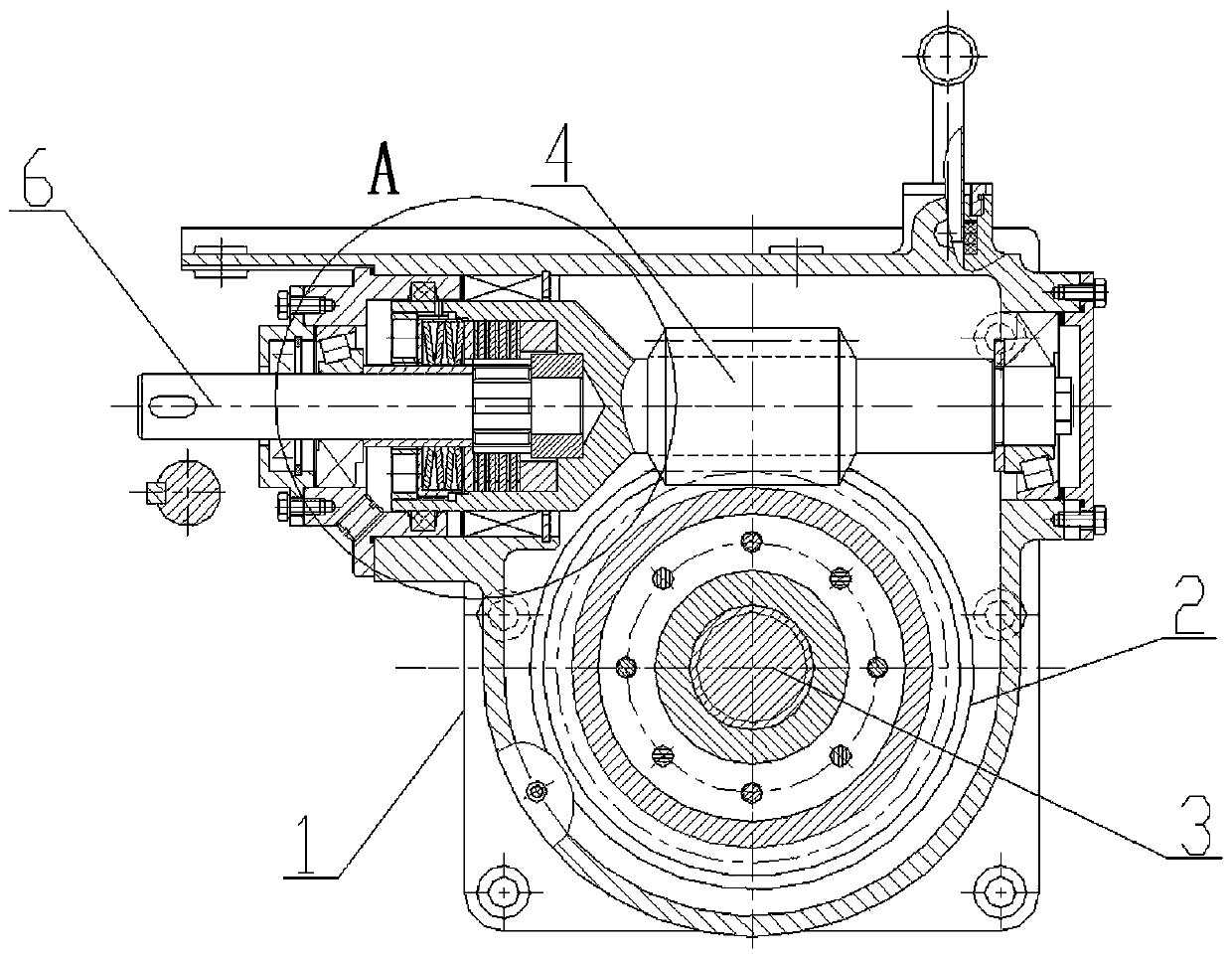

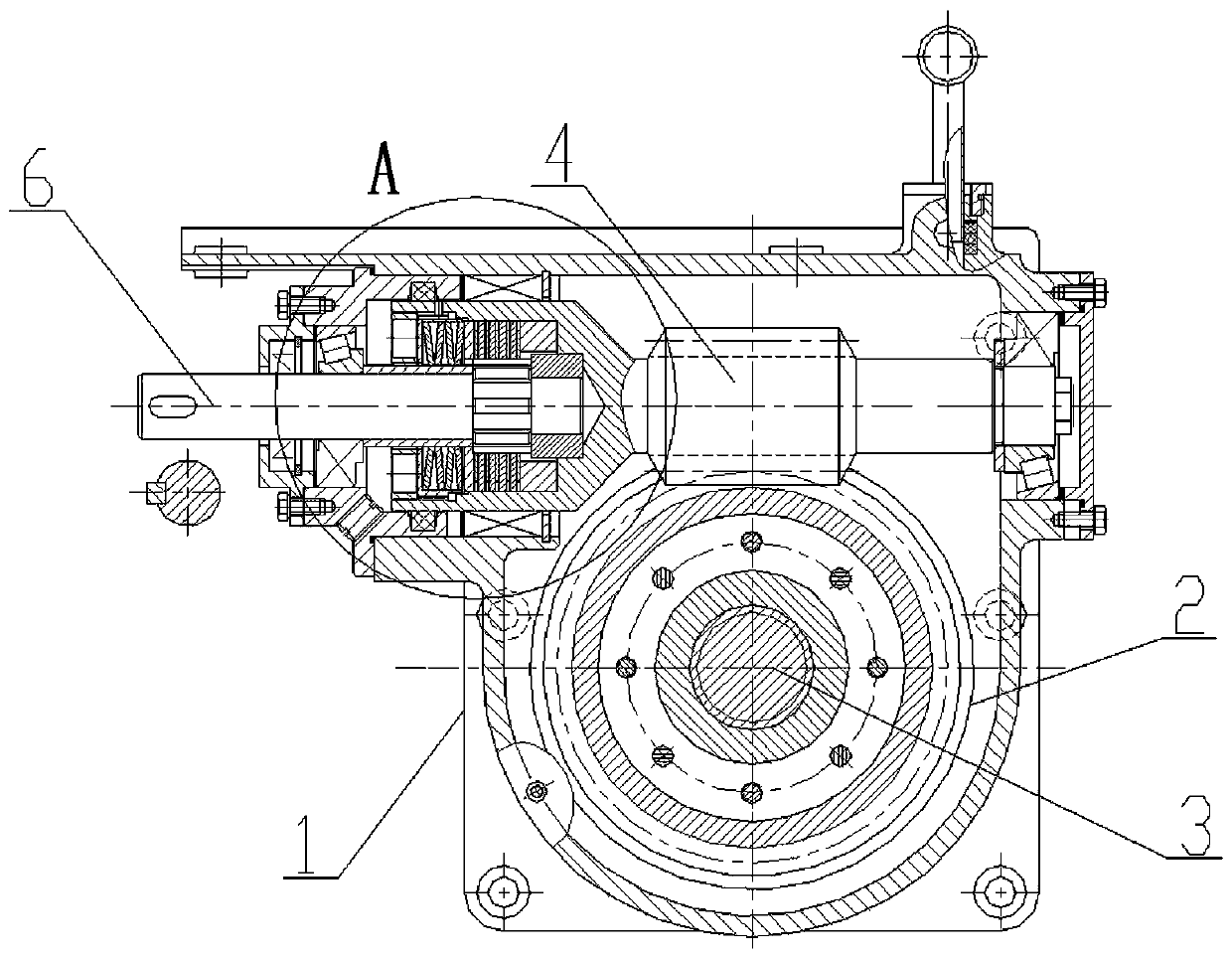

[0015] figure 1 , 2 Shown: a disc type overload protection anti-shock reducer includes box 1, worm gear 2, output shaft 3, worm 4, hollow shaft cavity 5, input shaft 6, bushing 7, steel friction plate 8, copper friction plate 9. Buffer disc 10, disc spring 11, pressure regulating cover 12, pressure regulating nut 13. The worm gear 2, the output shaft 3, and the worm screw 4 are set in the box body 1, the output shaft 3 is connected through the worm wheel 2, the worm gear 2 is meshed with the worm screw 4, one end of the worm screw 4 is supported on the box body 1 by a rib bearing, and the other end is set as a hollow shaft The cavity 5 is structured and supported on the box by bearings. An input shaft 6 is coaxially arranged in the hollow shaft cavity 5. The inner end of the input shaft 6 is supported in the hollow shaft cavity 5 by a sleeve or bearing, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com