Washing machine speed reducing clutch control method, speed reducing clutch and washing machine

A deceleration clutch and control method technology, applied in the field of washing machines, can solve problems such as noise, gear damage, life shortening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

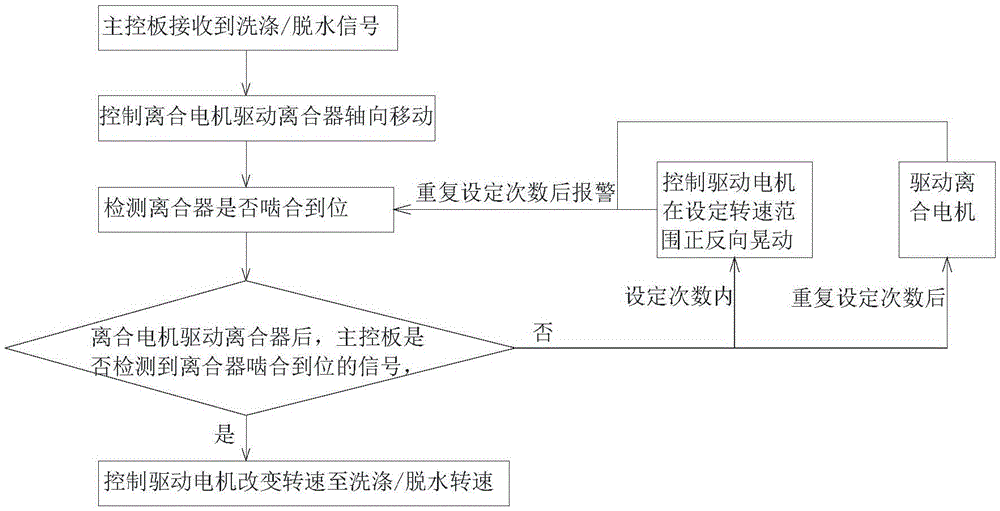

[0027] Such as figure 1 As shown in the present invention, a washing machine deceleration clutch control method, the steps are as follows:

[0028] Step 1. The main control board receives the washing / dehydration signal, and controls the clutch motor to drive the clutch to move axially;

[0029] Step 2. Check whether the clutch is in place. After the clutch motor runs in place, if the main control board detects the signal that the clutch is in place, control the driving motor to change the speed to the washing / spinning speed. If the main control board does not detect that the clutch is in place signal, the drive motor is controlled to reciprocate forward and reverse within the set speed range, and the clutch is engaged.

[0030] If the timing sequence of forward and reverse reciprocating motion of the driving motor is completed and the engagement in-position signal has not been detected, the clutch motor will run for another cycle, and the above detections will be repeated. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com