Device for carrying out the programming of rotary dobbies in weaving machines

A technology for weaving machinery and rotating electrical machines, applied in the field of program devices, can solve problems such as increased loom downtime, wrong selection process, and unfavorable loom production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

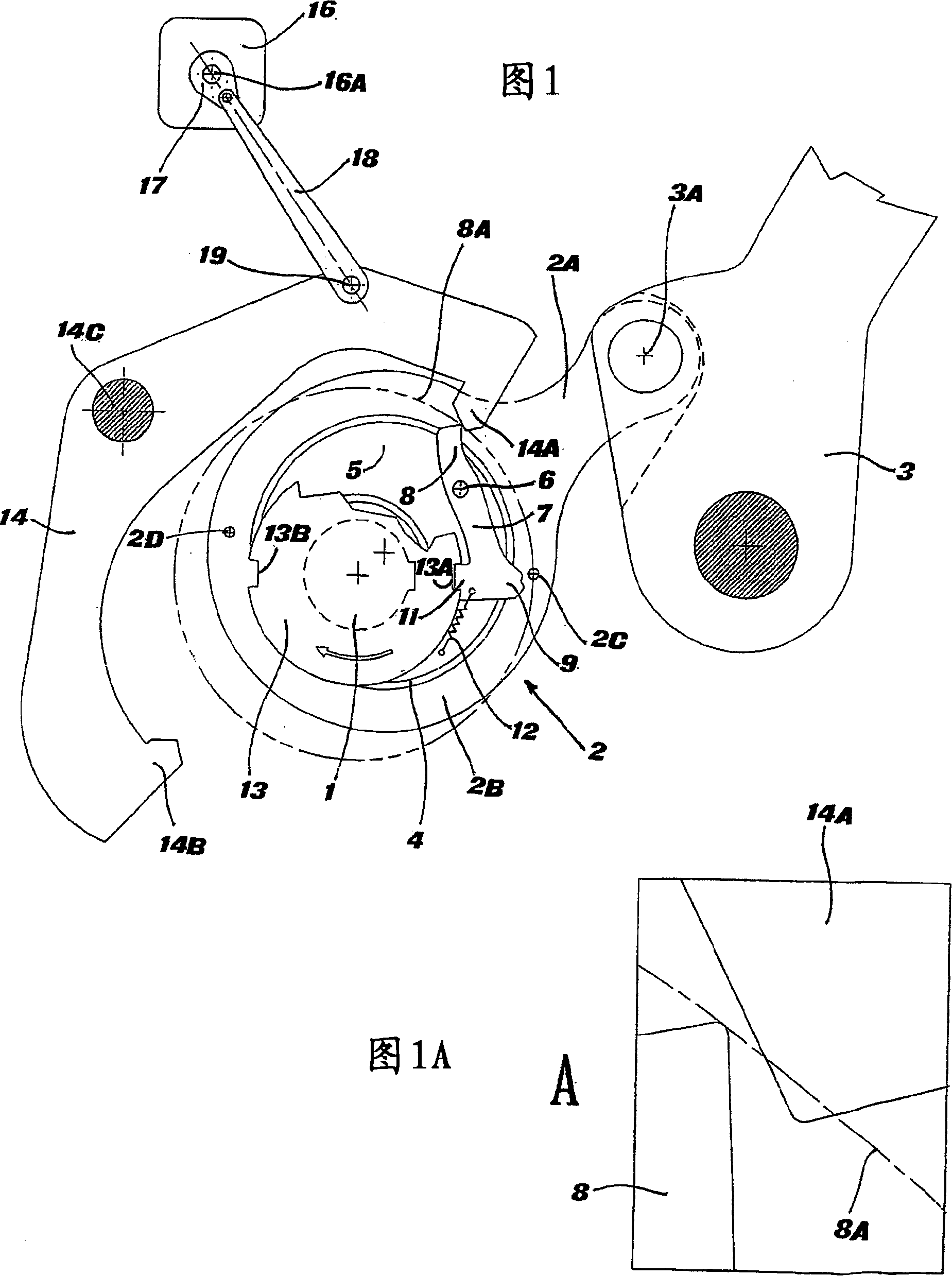

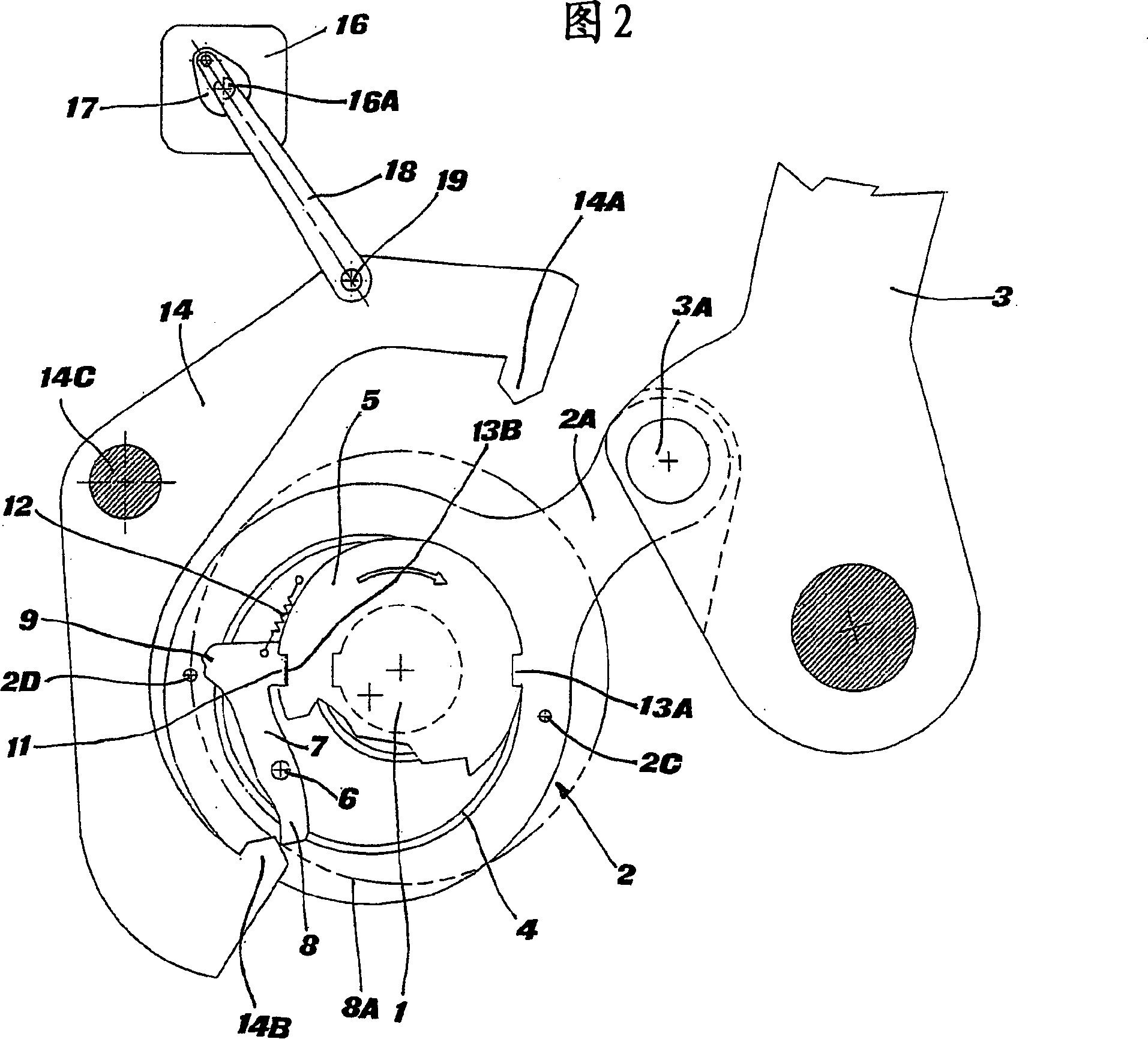

[0018] As shown in the drawings, the device according to the invention forms part of a dobby comprising a rotating shaft 1 on which a The connecting rod element 2, which can be made to have a protrusion 2A that is pivotally articulated at 3A with the operating lever 3 of the heald frame (not shown), and a substantially It is a circular ring 2B with two rollers 2C and 2D at opposite positions.

[0019] In the central part of the connecting rod 2 a bearing 4 has been inserted, on the inner ring of which an eccentric cam 5 has been arranged, it can also be seen that the eccentric cam can rotate relative to the shaft 1 .

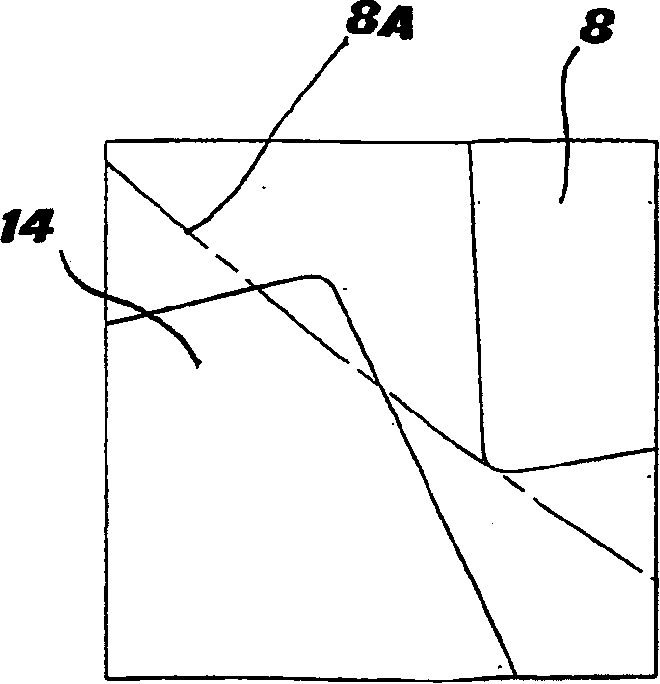

[0020] Via a rivet 6 or the like, a rocker 7 or selection lever has been provided in a pivoting manner on the eccentric cam 5, the selection lever has shaped ends 8 and 9 and has a Teeth 11 opposite said end 9 .

[0021] A spring 12, located between said eccentric cam 5 and the end 9 of said lever 7, exerts a pull-back action on said lever 7 and thus causes it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com