3D model internal hole digging type lightweight method based on function representation

A lightweight, model-based technology, applied in the field of hollow optimization of 3D printed objects, can solve problems such as rough shape representation and difficulty in accurately describing internal complex structures, and achieve the effect of large available design space, accurate representation and optimized solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

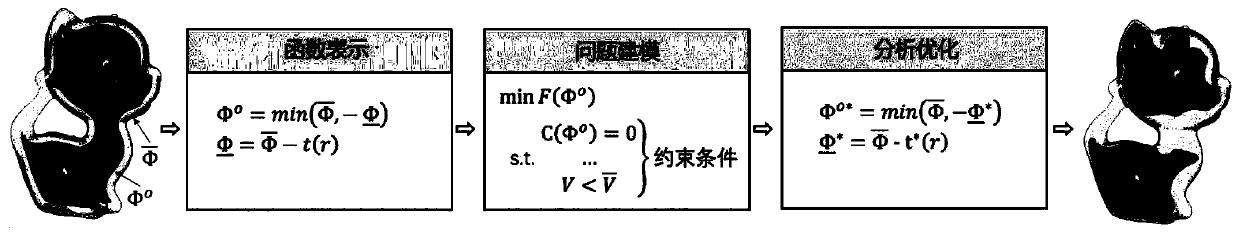

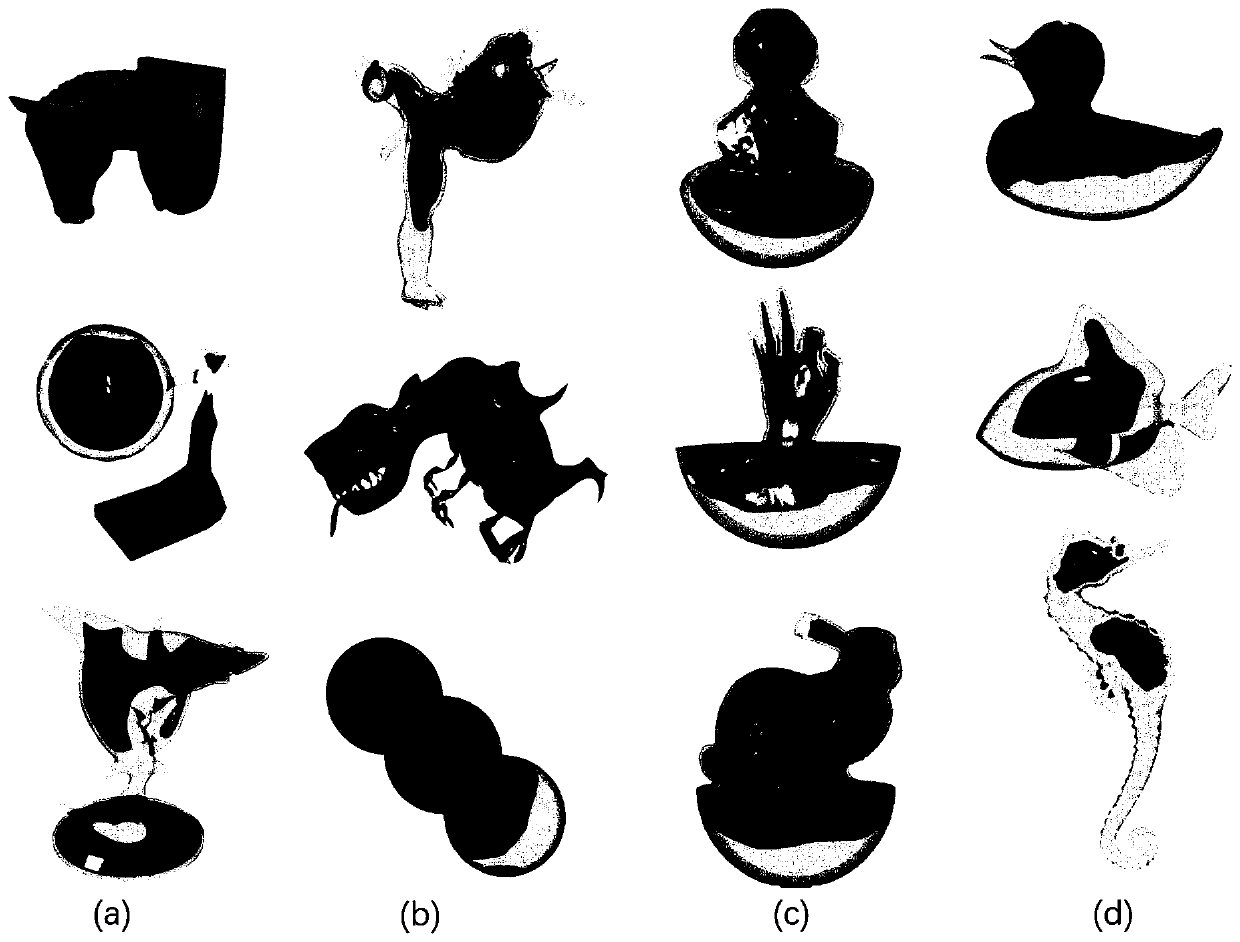

[0068] like figure 1 As shown, it is a schematic flow chart of the present invention. This embodiment takes standing stability as an example to illustrate the specific implementation of the present invention. It can be divided into three main steps: 3D model function representation with holes, problem model establishment, and optimization solution:

[0069] (1) 3D model function representation

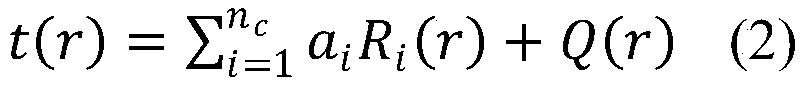

[0070] In order to obtain the interpolation function representing the inner and outer surfaces of the model, it is necessary to find the weight {a i} and {b i} value. Take the function value f=1 of the external control point, the function value f=-1 of the internal control point, and the function value f=0 of the control point on the model surface. Use the RBF radial basis function to calculate the distance valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com