Gear-change device

A technology of speed change device and speed change sleeve, which is applied in the direction of transmission parts, transmission control, and components with teeth, etc., which can solve the problems of cost, weight and tolerance disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

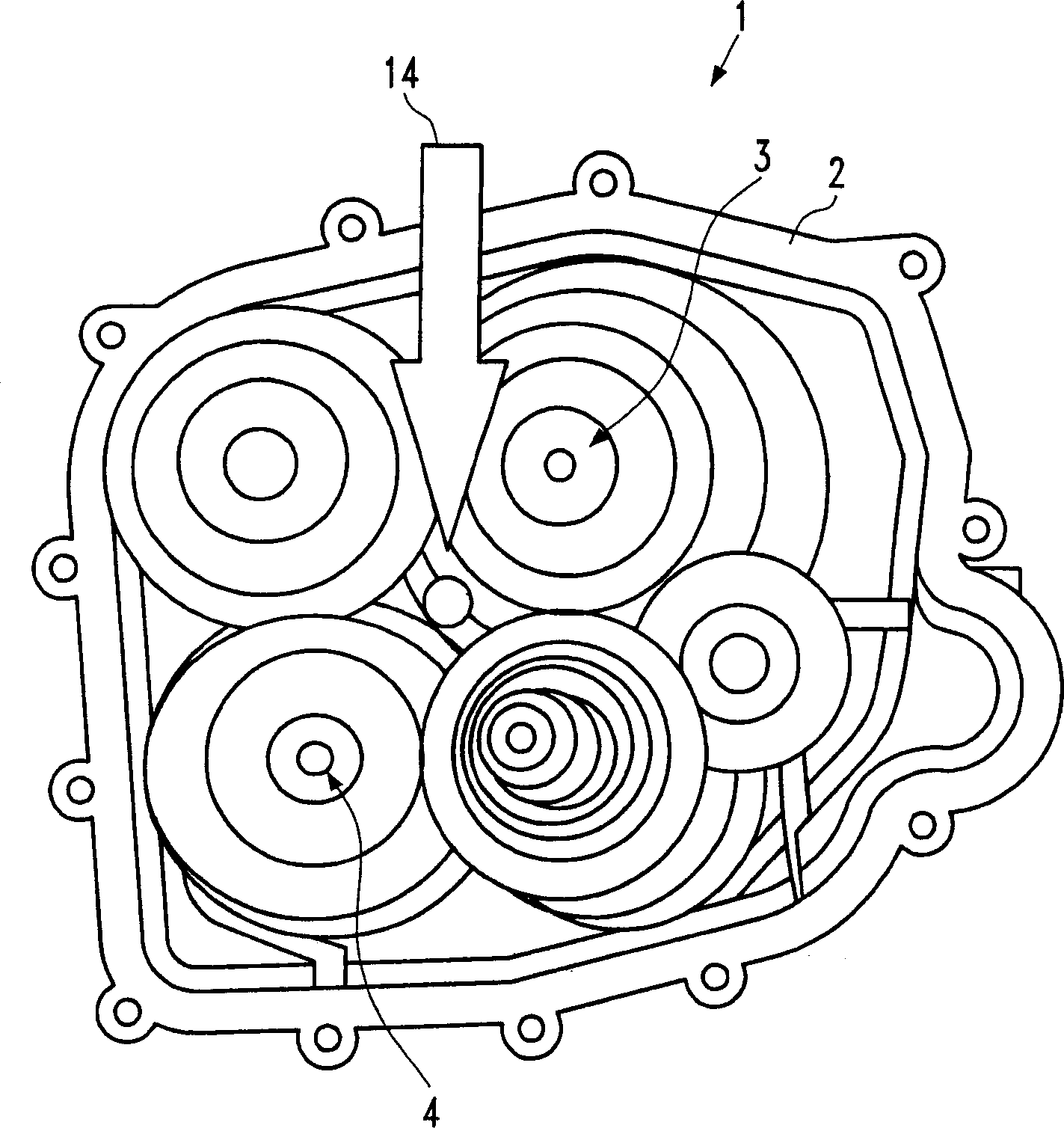

[0039] exist figure 1 In, an inventive transmission 1, in particular in the form of an automatic transmission, is shown in a schematic, somewhat simplified manner in order to illustrate the position of the inventive locking device 14 inside the transmission. The transmission device 1 includes a gearbox case 2, in an example, two gear shafts 3 and 4 are arranged inside the gearbox case 2.

[0040] A locking device 14, indicated by an arrow, is arranged between the pinion shafts 3 and 4, making possible the interlocking of the shifting sleeves arranged on the pinion shafts 3 and 4, which will be explained in more detail below. It goes without saying that the shifting device 1 includes all other elements of the shifting device, the description of which is omitted here since it is not useful for explaining the principles of the invention.

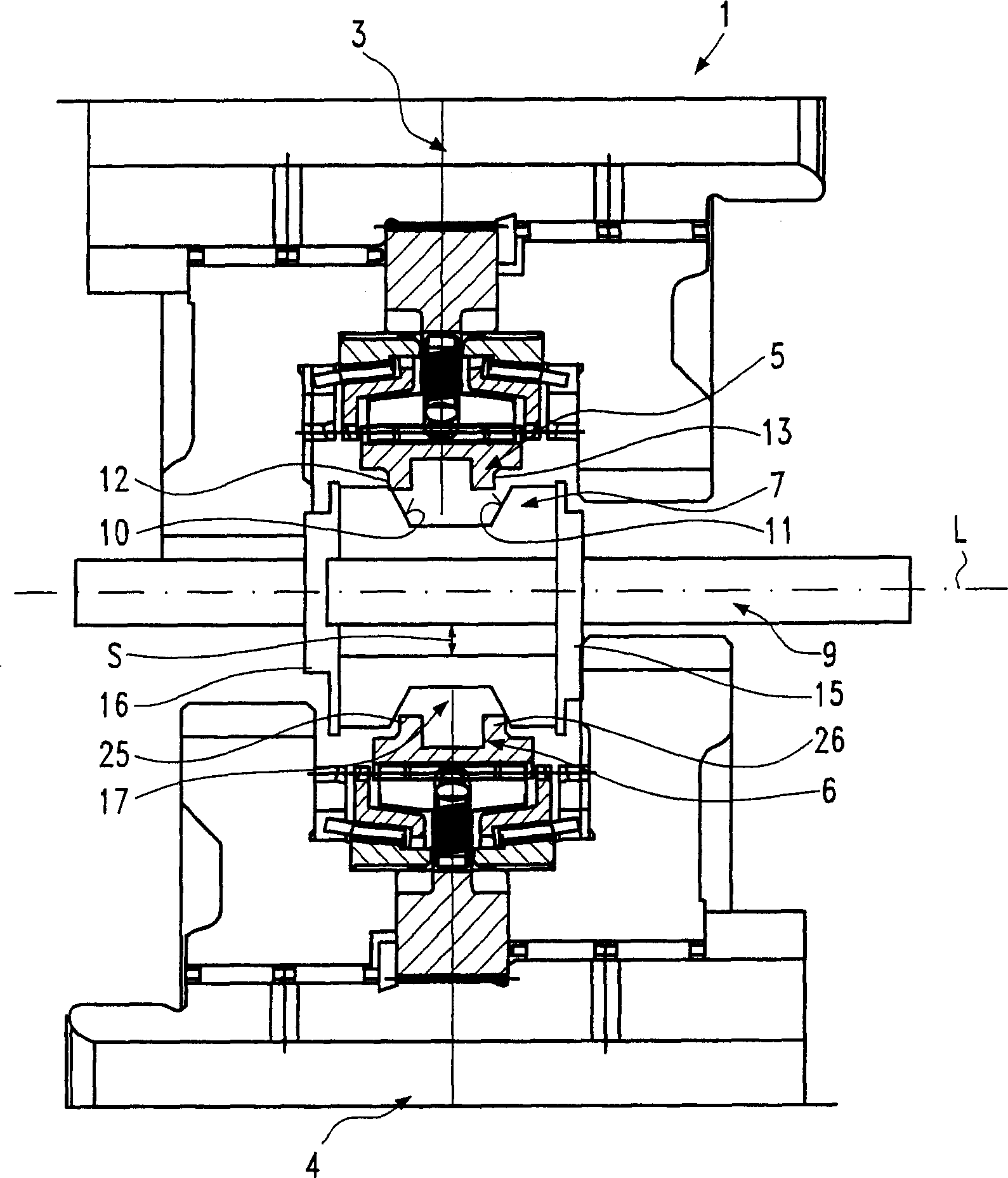

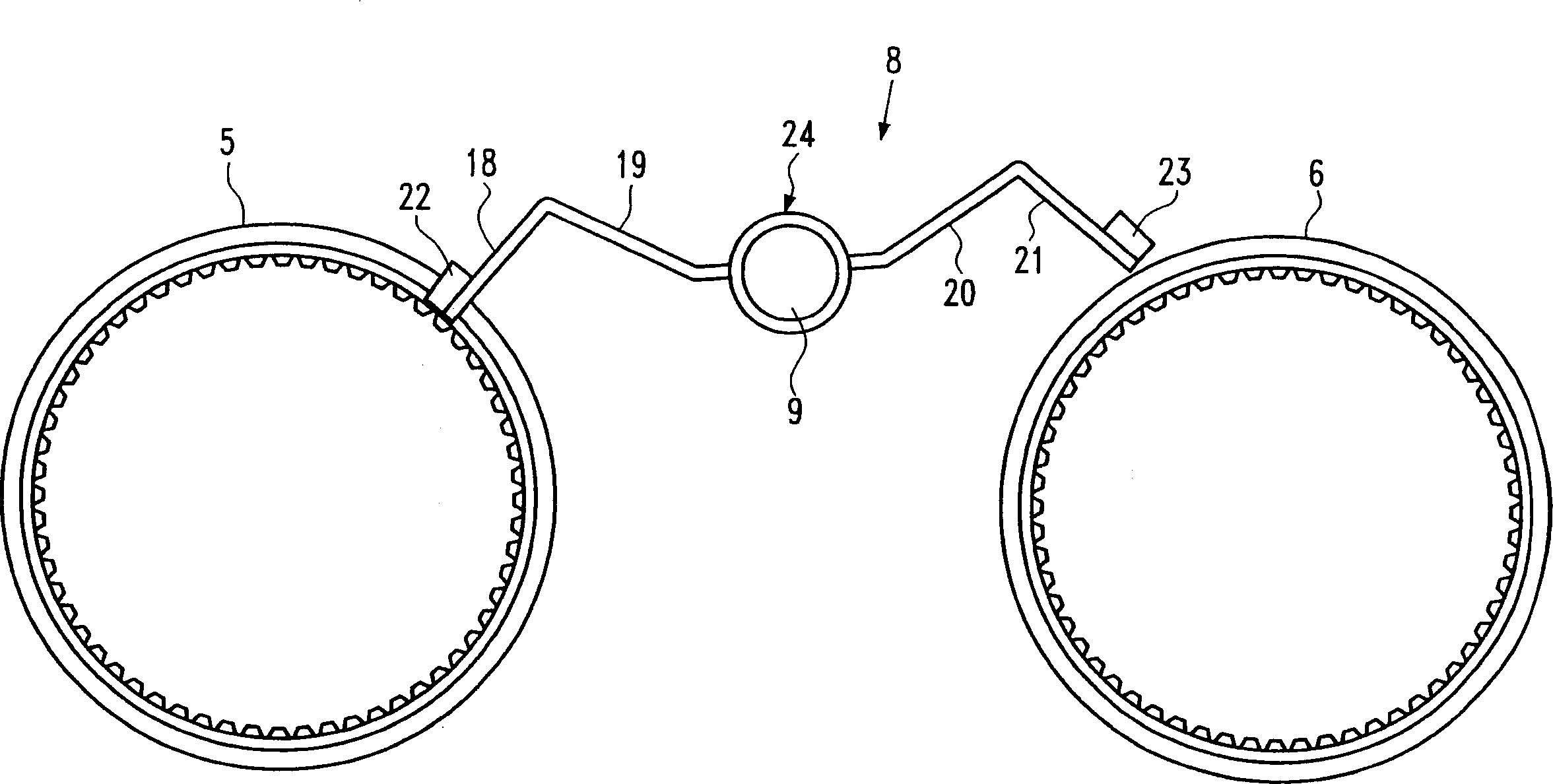

[0041] figure 2 shows the details of the transmission device 1 of the present invention, from figure 2 The pinion shafts 3 and 4 can agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com