Multifunctional filling non-woven cloth and manufacturing method thereof

A non-woven fabric and multi-functional technology, applied in the field of non-woven fabrics, can solve the problems of high warmth retention and high elasticity at the same time, and achieve the advantages of fragrance distribution, avoiding the separation of fiber net layers, protecting magnets and stabilizing the position of magnets Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of the above-mentioned multifunctional non-woven fabric for filling, the method comprises the following steps:

[0038] (1) Fiber web preparation: The surface layer fiber web 1 and the inner layer fiber web 5 are made by the process of carding or air-laying and then cross-laying; using the method of carding or air-laying low-melting short fibers The upper bonded fiber web 2 and the lower bonded fiber web 4 are prepared respectively; the middle layer fiber web 3 in the form of honeycomb cotton is made by carding into a web through a vertical web laying process.

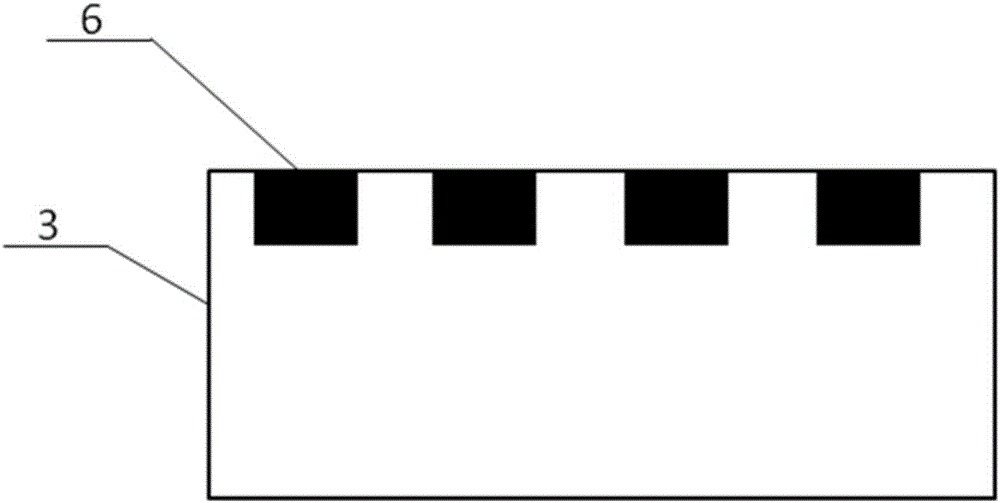

[0039] (2) Slotting of the fiber web: grooves are made on the upper surface of the middle-layer fiber web 3 . The middle layer fiber web 3 is formed by vertical laying, and the depth direction of the grooves is consistent with the thickness direction of the middle layer fiber web 3, and the grooves are carried out along the thickness direction of the middle layer fiber web 3, so that the mid...

Embodiment 1

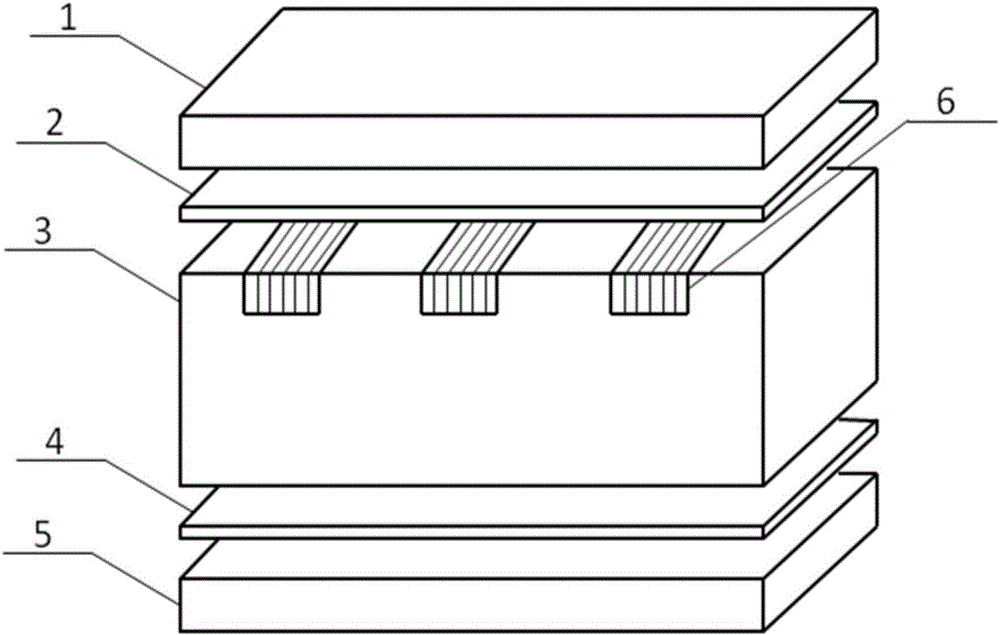

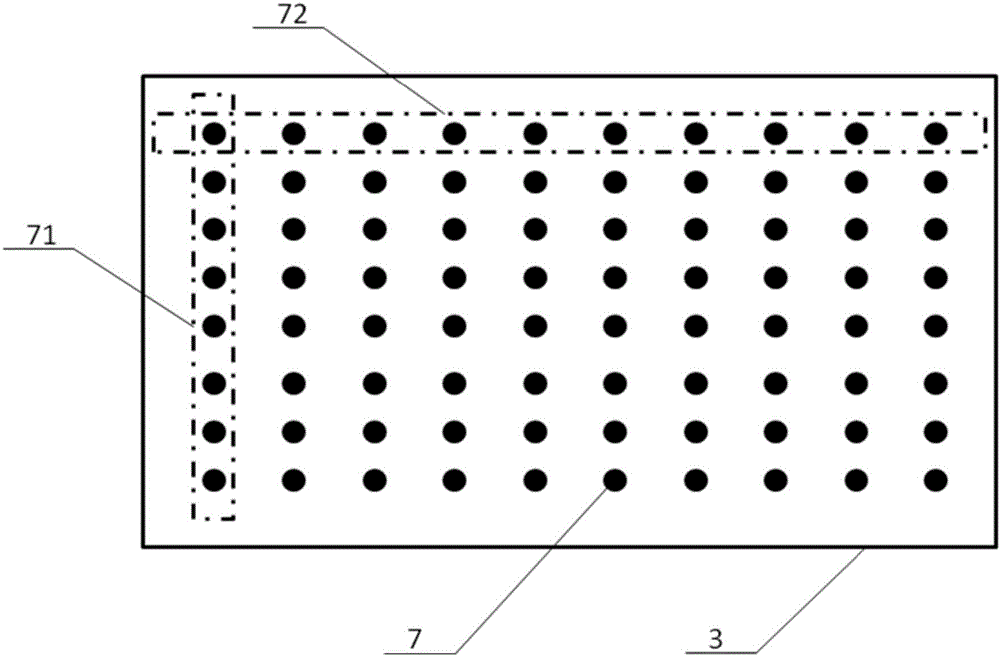

[0073] see Figure 1 to Figure 4 , a multifunctional non-woven fabric for filling, which is composed of a surface layer fiber web 1, an upper bonding fiber web 2, a middle layer fiber web 3, a lower bonding fiber web 4, and an inner layer fiber web 5. The upper surface of the middle layer fiber web 3 A number of grooves are provided, the grooves are filled with lavender 6, the lower surface of the middle layer fiber web 3 is provided with a number of thin magnets 7, the thin magnets 7 are embedded in the lower surface of the middle layer fiber web 3, and the upper adhesive fiber web 2 will The surface layer fiber web 1 and the middle layer fiber web 3 are consolidated together, and the lower bonding fiber web 4 consolidates the middle layer fiber web 3 and the inner layer fiber web 5 together.

[0074] A preparation method of the above-mentioned multifunctional non-woven fabric for filling, the preparation method comprises the following steps in sequence:

[0075](1) Fiber we...

Embodiment 2

[0085] The basic content is the same as that of Example 1, except that:

[0086] The surface layer fiber web 1 and the inner layer fiber web 5 are made by air-laid and then cross-laminated.

[0087] The upper bonded fiber web 2 and the lower bonded fiber web 4 are prepared by air-laid method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com