Clean electrospinning method

A technology of roving and spinning solution, which is applied in textiles and papermaking, fiber treatment, filament/thread forming, etc. It can solve problems such as difficulties in realization, achieve the effects of increasing strength, reducing hairiness, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

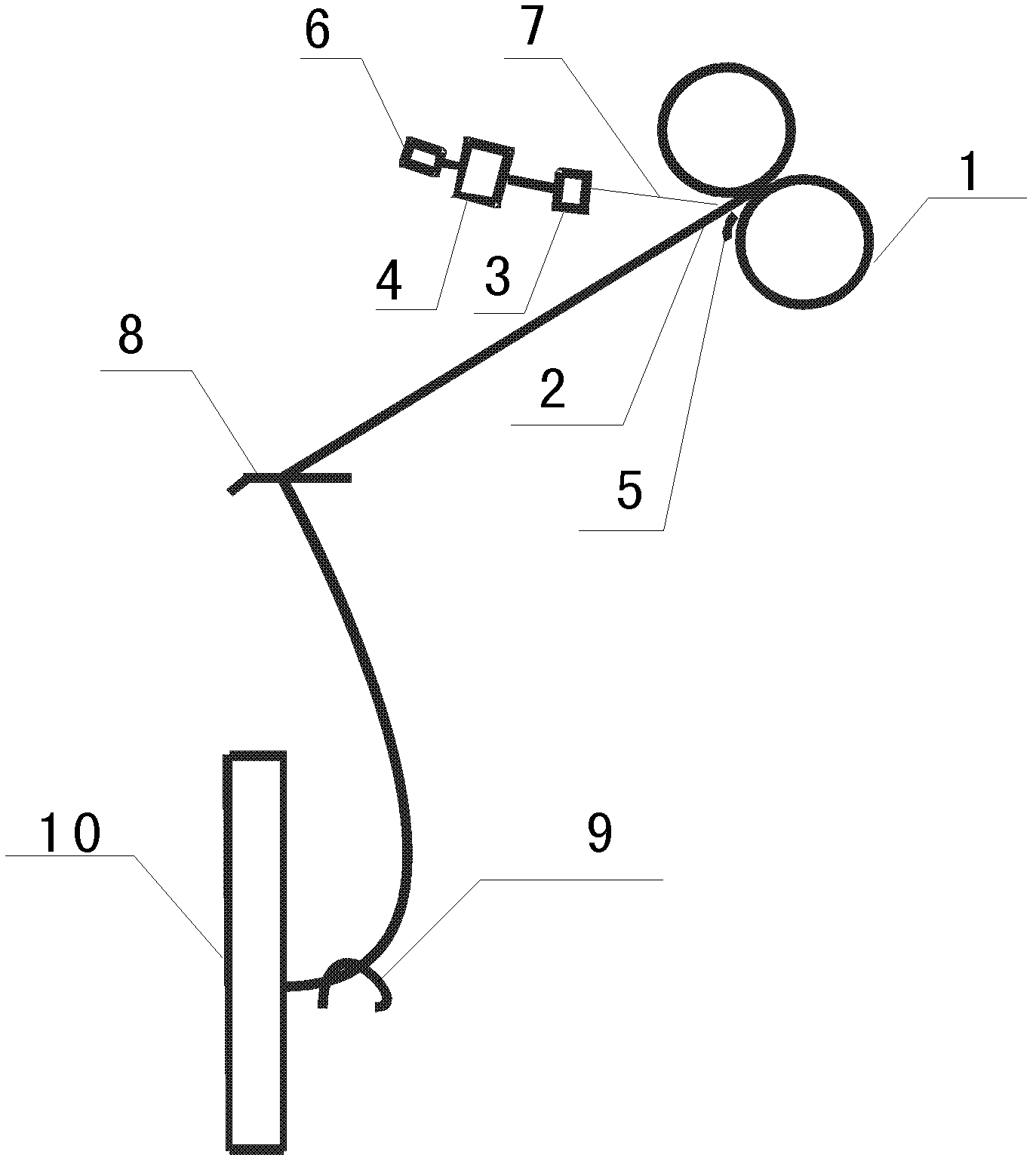

Method used

Image

Examples

Embodiment 1

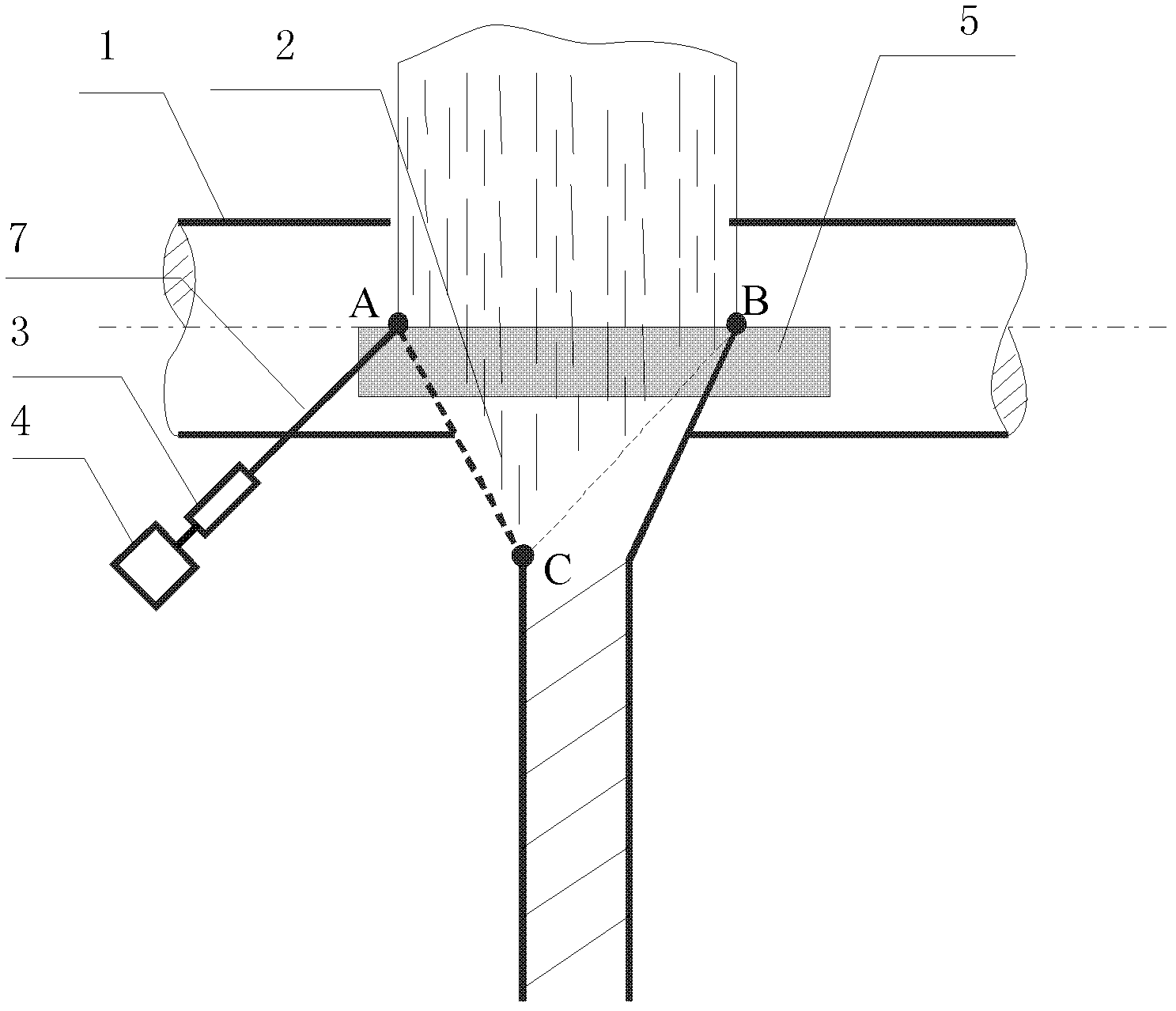

[0030] Spinning yarn with less hairiness on FA506 cotton ring spinning frame:

[0031] The method is: see figure 2 , the strands 2 output from the front roller 1 enter the twisting triangle ABC for twisting, a capillary spinneret 3 and a liquid flow controller 4 are arranged obliquely above the twisting triangle ABC, and the material of the grounded pole plate 5 is stainless steel metallic material. Dissolve the PET slices in a solvent of trifluoroacetic acid and dichloromethane, the volume ratio of trifluoroacetic acid and dichloromethane is 6:4, the concentration of PET is 0.2g / ml, stir at room temperature until it dissolves into a homogeneous solution, As the spinning solution 6, it is injected into the capillary spinneret 3 through the liquid flow controller 4, the spinning solution 6 is connected to the positive pole of the high-voltage power supply, and the grounded plate 5 is connected to the negative pole of the high-voltage power supply. 16~22kV, the distance between...

Embodiment 2

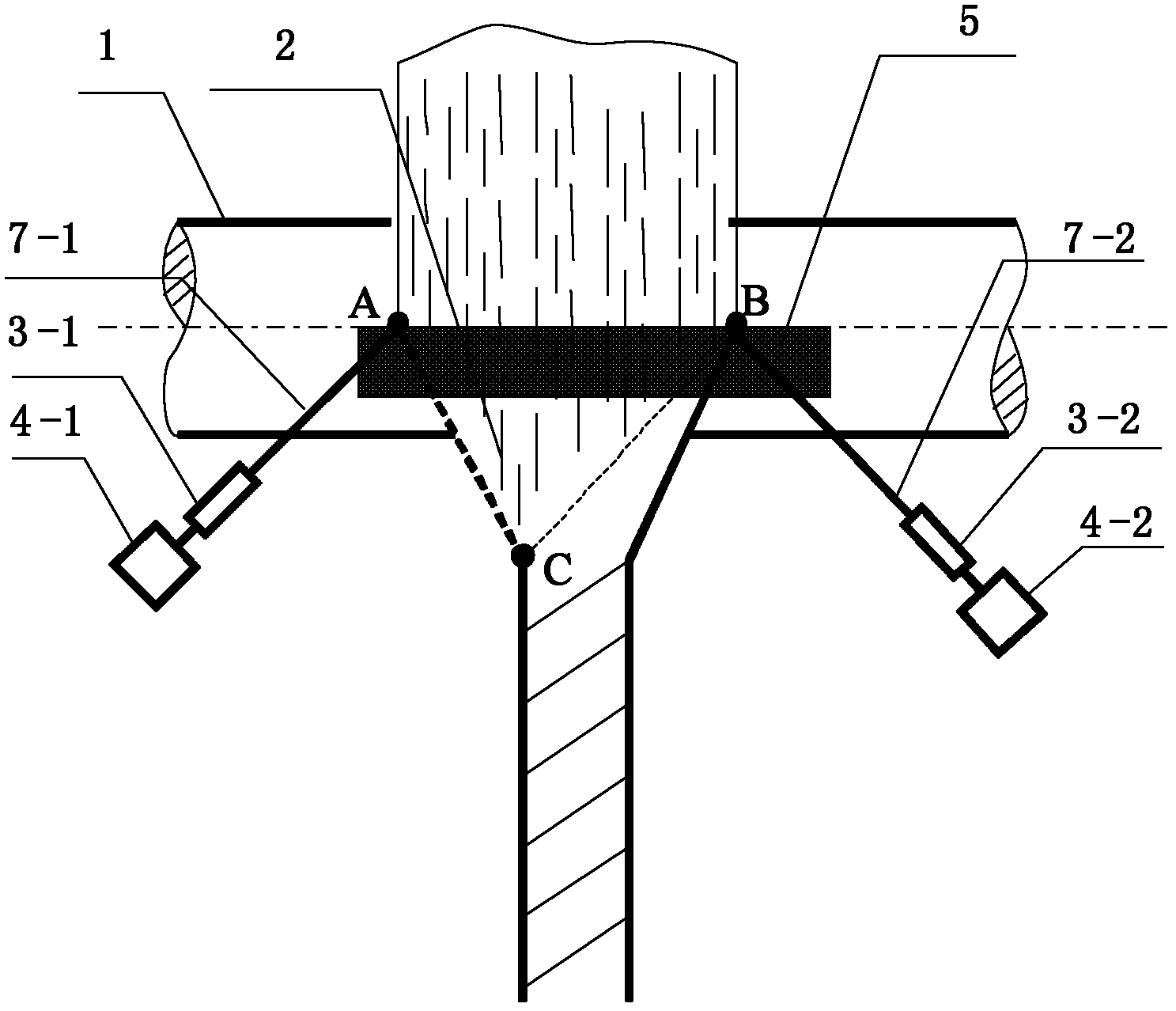

[0033] Spinning yarn with less hairiness on FB501 wool spinning ring spinning frame:

[0034] The method is: see image 3 , the strands 2 output from the front roller 1 enter the twisting triangular area ABC for twisting, and capillary spinnerets 3-1, 3-2 and liquid flow controllers 4-1, 4- are arranged above the twisting triangular area ABC 2. The material of the grounded pole plate 5 is stainless steel. Dissolve the PET slices in a solvent of trifluoroacetic acid and dichloromethane, the volume ratio of trifluoroacetic acid and dichloromethane is 6:4, the concentration of PET is 0.2g / ml, stir at room temperature until it dissolves into a homogeneous solution, As the spinning solution 6, it is injected into the capillary spinneret 3-1 and the capillary spinneret 3-2 respectively through the liquid flow controller 4-1 and the liquid flow controller 4-2, and the spinning solution 6 Connect the positive pole of the high-voltage power supply, the pole plate 5 is connected to th...

Embodiment 3

[0036] Spinning yarn with less hairiness on FZ501 hemp spinning ring spinning frame:

[0037] The method is: see image 3 , the strands 2 output from the front roller 1 enter the twisting triangular area ABC for twisting, and capillary spinneret 3-1, capillary spinneret 3-2 and liquid flow controller 4- are arranged above the twisting triangular area ABC 1. The material of the liquid flow controller 4-2 and the grounded plate 5 is stainless steel. Dissolve the PET slices in a solvent of trifluoroacetic acid and dichloromethane, the volume ratio of trifluoroacetic acid and dichloromethane is 6:4, the concentration of PET is 0.2g / ml, stir at room temperature until it dissolves into a homogeneous solution, As the spinning solution 6, it is injected into the capillary spinneret 3-1 and the capillary spinneret 3-2 respectively through the liquid flow controller 4-1 and the liquid flow controller 4-2, and the spinning solution 6 Connect the positive pole of the high-voltage power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com