Hydrophobic material and preparation method thereof

A hydrophobic and hydrophobic surface technology, applied in the field of materials, can solve the problems of poor mechanical properties of products, expensive raw materials of hydrophobic materials, cumbersome and complicated processes, etc., and achieve the effect of simple method, low price and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

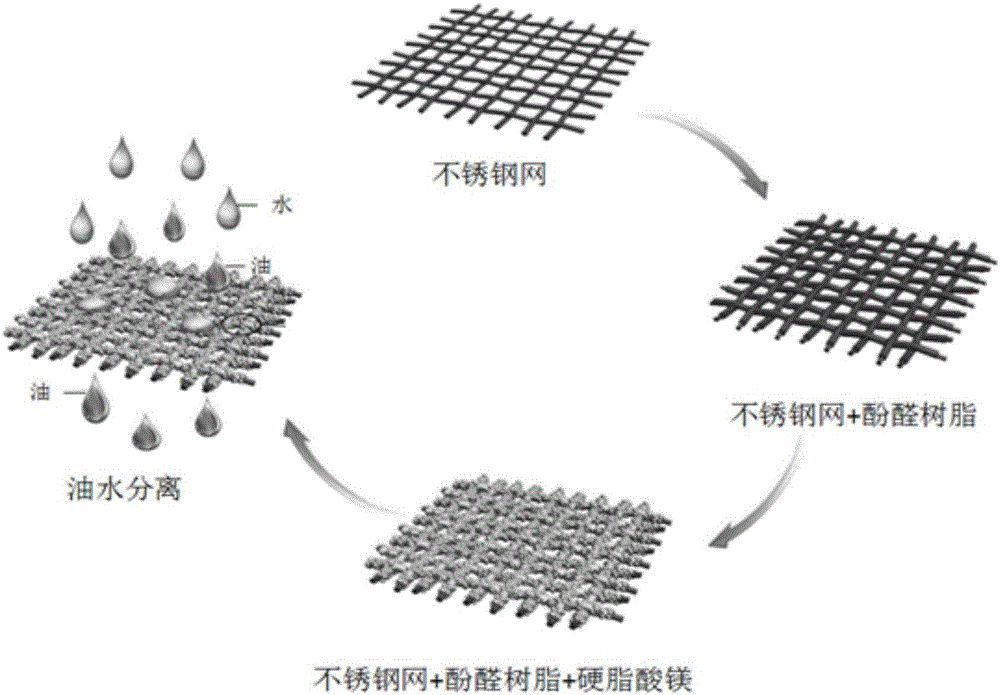

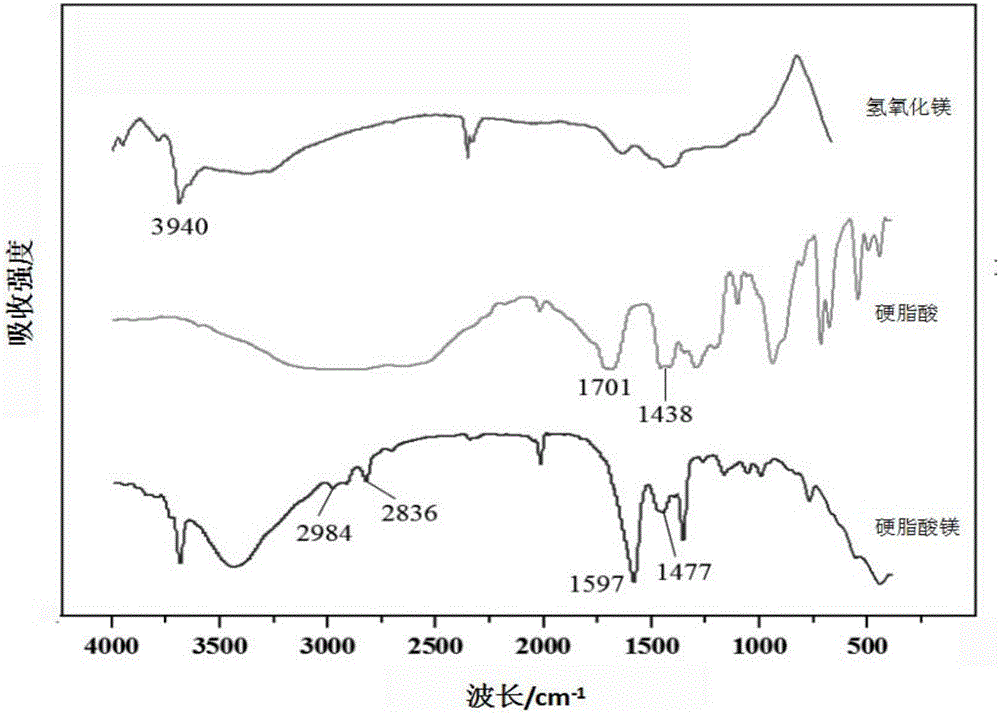

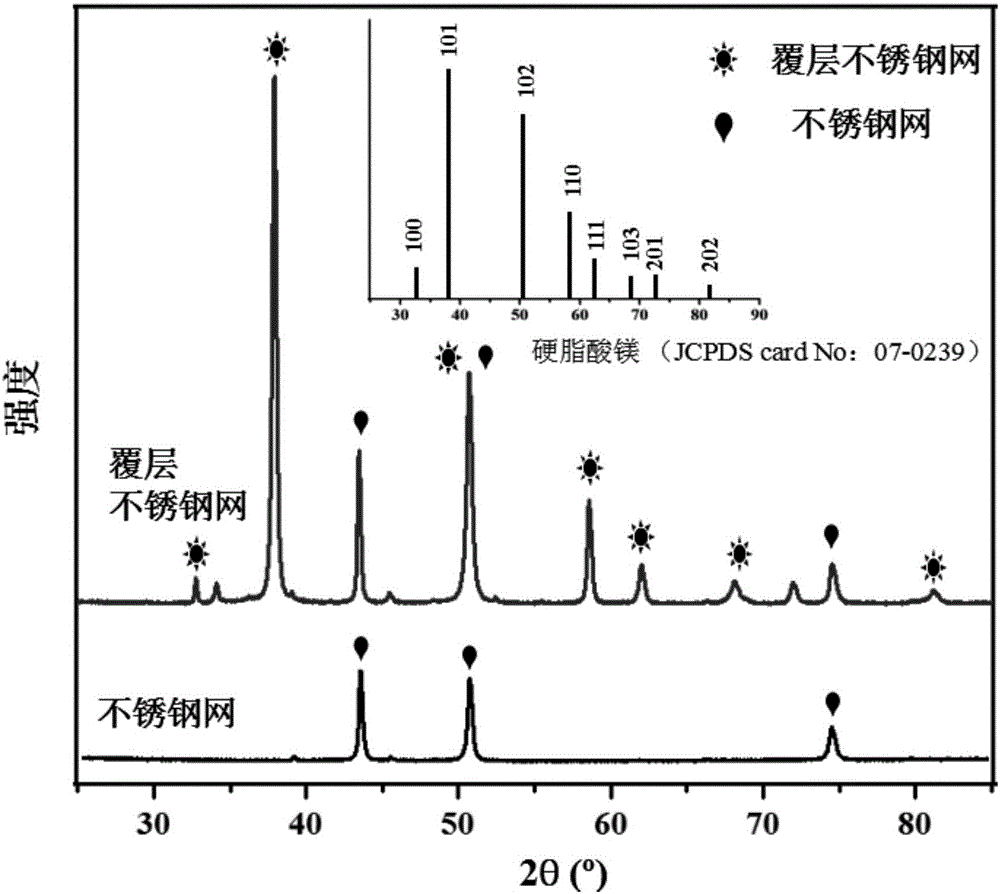

[0048] In the preparation method according to the present invention, stearic acid and magnesium hydroxide are used as raw materials, dispersed in absolute ethanol, reacted for a period of time under stirring conditions, and then dried in an oven for solid powder obtained by suction filtration. The dried powder is evenly bonded to various cleaned substrates under the bonding action of phenolic resin, and a hydrophobic material with excellent hydrophobic properties and mechanical properties can be obtained. This preparation process does not require any complicated experimental equipment, does not add any cross-linking agent, organic solvent, initiator, and ultraviolet induction conditions. It is green and pollution-free, with simple process and convenient operation. It is an efficient, fast and environmentally friendly method for preparing hydrophobic materials.

[0049] The phenolic resin used in the hydrophobic material according to the present invention and its preparation met...

Embodiment 1

[0055] 1) Stearic acid modified Mg(OH) 2 preparation of

[0056] 1.995g Mg(OH) 2 The powder (average particle size is 20-30nm) and 0.285g stearic acid are evenly dispersed in 30ml absolute ethanol, stirred at 60°C for 30min, filtered, washed twice with absolute ethanol, and the synthesized solid powder is dried in an oven at 60°C 2h;

[0057] 2) 400-mesh stainless steel mesh is used as the base material, washed with acetone, absolute ethanol, and deionized water under ultrasonic conditions for 15 minutes, and dried in an oven at 60°C for use;

[0058] 3) 8g of thermosetting phenolic resin (BR P832682 (Shanghai Macklin Biochemical Technology Co., Ltd.)) is dispersed in 40ml of deionized water, and the substrate is soaked in the resin solution for 10min. , the amount of phenolic resin is about 8g;

[0059] 4) Preparation of phenolic resin-stearic acid-Mg(OH) 2 Hydrophobic coating

[0060] Use a 400-mesh sieve to evenly distribute the stearic acid-modified magnesium hydroxi...

Embodiment 2

[0065] 1) Prepare stearic acid modified Mg(OH) 2

[0066] 1.995g Mg(OH) 2 Powder (average particle size 20-30nm) and 0.2g stearic acid are evenly dispersed in 30ml of absolute ethanol, stirred at 60°C for 30min, filtered, washed twice with absolute ethanol, and the synthesized solid powder is dried in an oven at 60°C 2h.

[0067] 2) 400-mesh stainless steel mesh is used as the base material, washed with acetone, absolute ethanol, and deionized water under ultrasonic conditions for 15 minutes, and dried in an oven at 60°C for use;

[0068] 3) Disperse 8g of thermosetting phenolic resin in 40ml of deionized water, soak various substrates in the resin solution for 10min, and use as you go;

[0069] 4) Preparation of phenolic resin-stearic acid-Mg(OH) 2

[0070] Use a 400-mesh sieve to evenly distribute the magnesium hydroxide powder on the surface of the substrate coated with phenolic resin obtained in step 3), and heat at 150° C. for 20 minutes with microwave-assisted heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com