Methanol cracking catalyst and preparation method thereof

A methanol cracking and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as high cost, and achieve short reaction time and high reaction efficiency. , the effect of high methanol conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

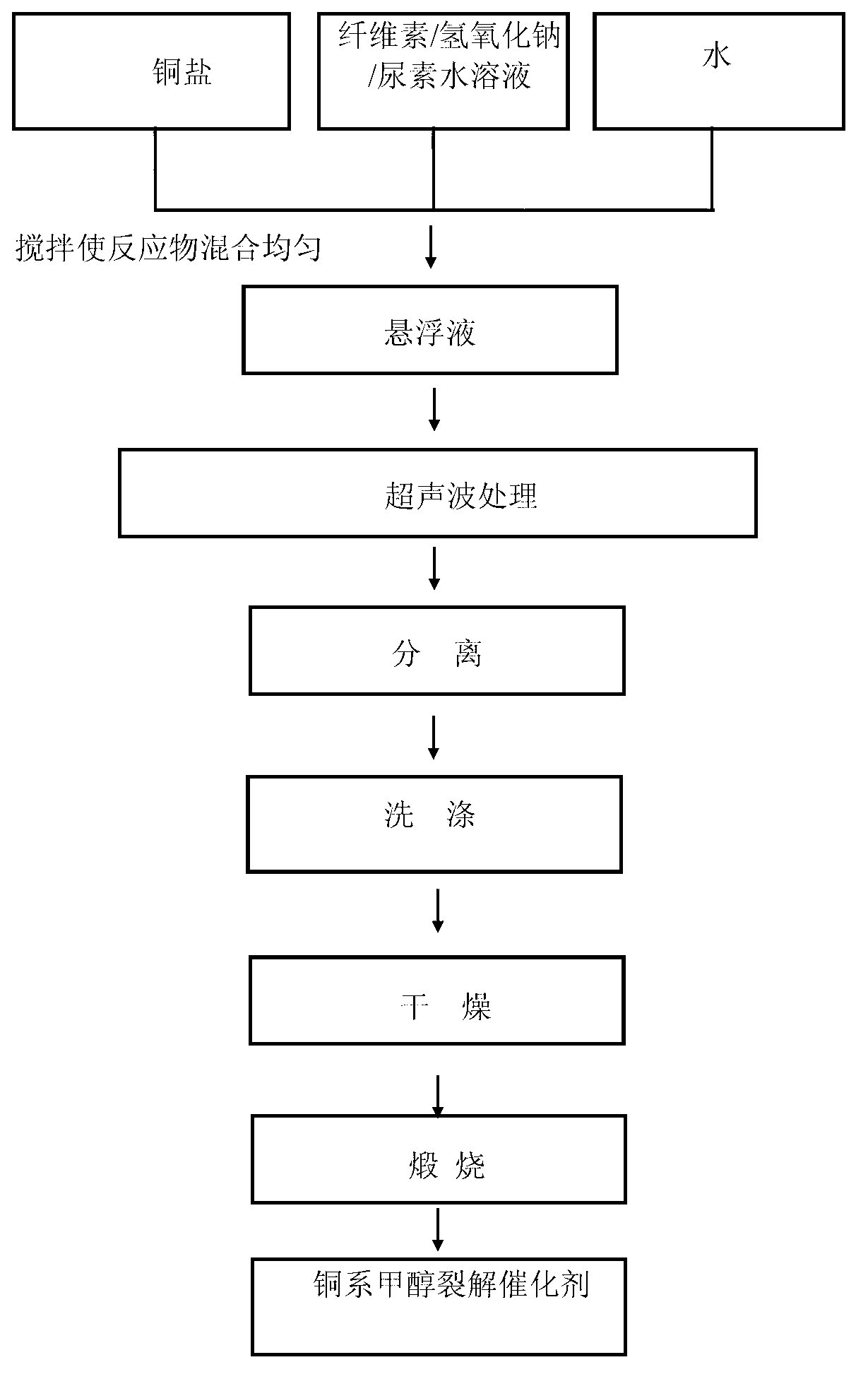

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of cellulose solution

[0049] 1A) Add 3.5g of sodium hydroxide and 6g of urea to 40.5g of water, stir and dissolve evenly to form a sodium hydroxide / urea aqueous solution, wherein the mass percentage content of sodium hydroxide is 7%, and the mass percentage concentration of urea is 12% ; The mass ratio of sodium hydroxide to urea is 7:12;

[0050] 1B) Add 3 g of cellulose into the above sodium hydroxide / urea solution, and stir to obtain a uniformly dispersed cellulose solution, wherein the mass percentage concentration of cellulose in the cellulose solution is 6%.

[0051] 2. Ultrasonic treatment

[0052] 2A) Add 0.34g of copper chloride and 10ml of the above cellulose solution to 30ml of water, stir evenly until there is no precipitation, and prepare a suspension, wherein the amount of copper ion added to the cellulose solution is 5mL per mmol; The amount of water added by copper ions is 15mL;

[0053] 2B) Put the suspension into an ultrasonic react...

Embodiment 2

[0062] In addition to the preparation of the cellulose solution, the amount of cellulose used is 3.522g, and the mass percentage concentration of the cellulose solution is 7.044%; the copper salt in the ultrasonic treatment process is copper nitrate, and the mass of copper nitrate is 0.241g. The amount of ions added to the cellulose solution is 10mL; the amount of water added per millimolar of copper ions is 30mL, and the temperature is 90±2°C; the frequency of ultrasonic treatment is 24kHz; The time is 1S (on), the ultrasonic stop generation time (ie intermittent time) is 1S (off), and the ultrasonic treatment time is 20min; the calcination temperature during the calcination treatment is 400 ° C, and the calcination time is 6h, the rest is the same as Example 1 .

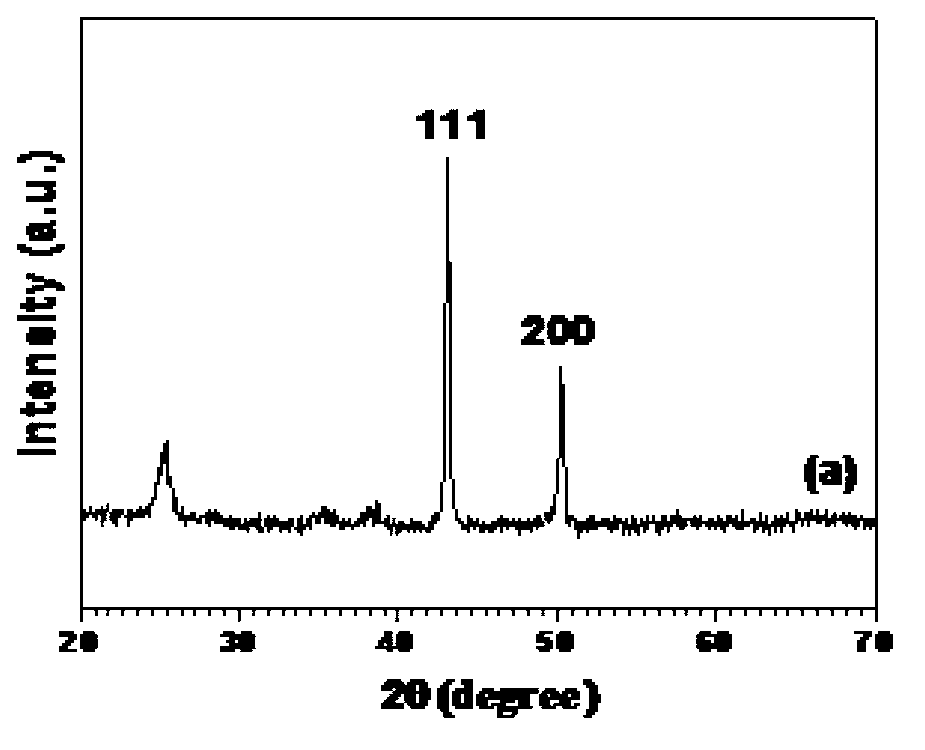

[0063] The composition and purity of the prepared copper-based methanol cracking catalyst were analyzed by X-ray diffraction. image 3 shown. The X-ray diffraction pattern of the product shows that the product co...

Embodiment 3

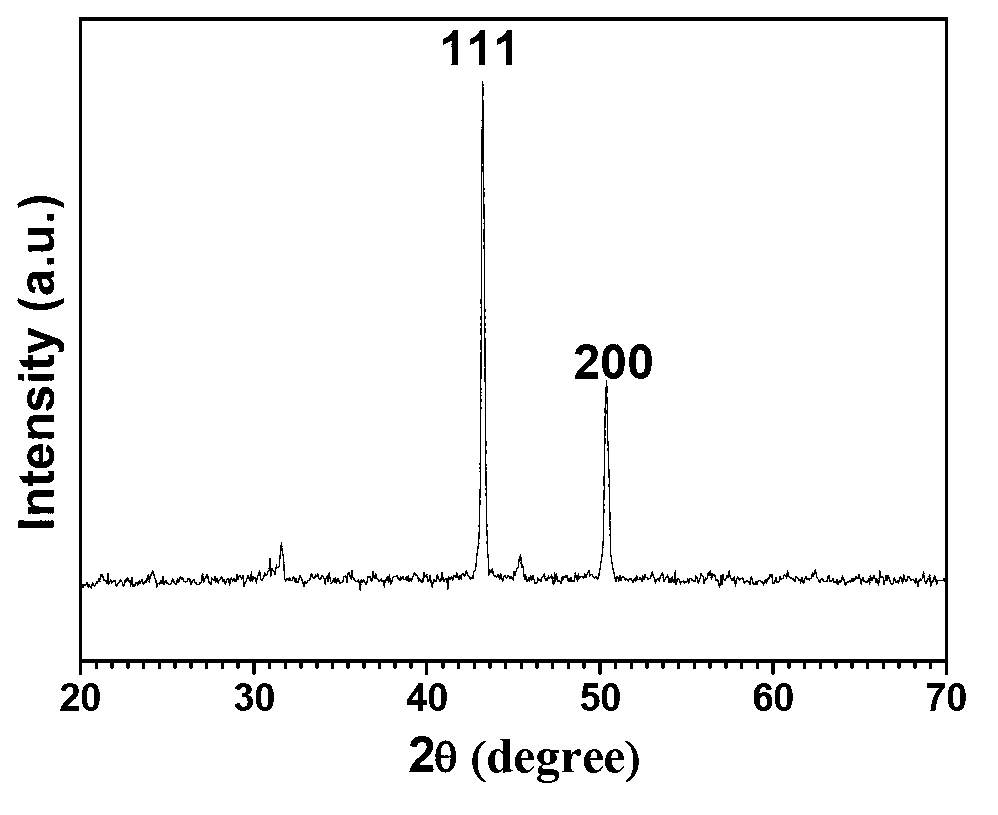

[0065] In addition to the process of preparing the cellulose solution, 5.0g of sodium hydroxide and 7.5g of urea were added to 37.5g of water to form a sodium hydroxide / urea solution, wherein the mass percent content of sodium hydroxide was 10%, and the mass percent concentration of urea was 15%; the mass ratio of sodium hydroxide to urea is 10:15; the dosage of cellulose is 3.522g, and the mass percentage concentration of the cellulose solution is 7.044%; the copper salt in the ultrasonic treatment process is copper acetate, and the amount of copper acetate is The mass is 0.199g, the amount of cellulose solution added per millimoles of copper ions is 10mL; the amount of water added per millimoles of copper ions is 30mL, the temperature is 90±2℃; the frequency of ultrasonic treatment is 20kHz; the pulse time of ultrasonic waves It is 5S:5S, that is, the duration of the ultrasonic wave is 5S (on), the ultrasonic stop generation time (i.e. intermittent time) is 5S (off), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com