Antenna manufacturing method based on PDS technology, and antenna manufactured through antenna manufacturing method

A manufacturing method and antenna technology, applied in the field of electronic communication, can solve the problems of antenna affecting performance, weak adhesion, cost impact, etc., and achieve the effects of simplifying the printing process, saving the via process, and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The antenna manufacturing method based on the PDS process in this embodiment specifically includes the following steps:

[0045] (1) Prepare a bonding ink with strong adhesion;

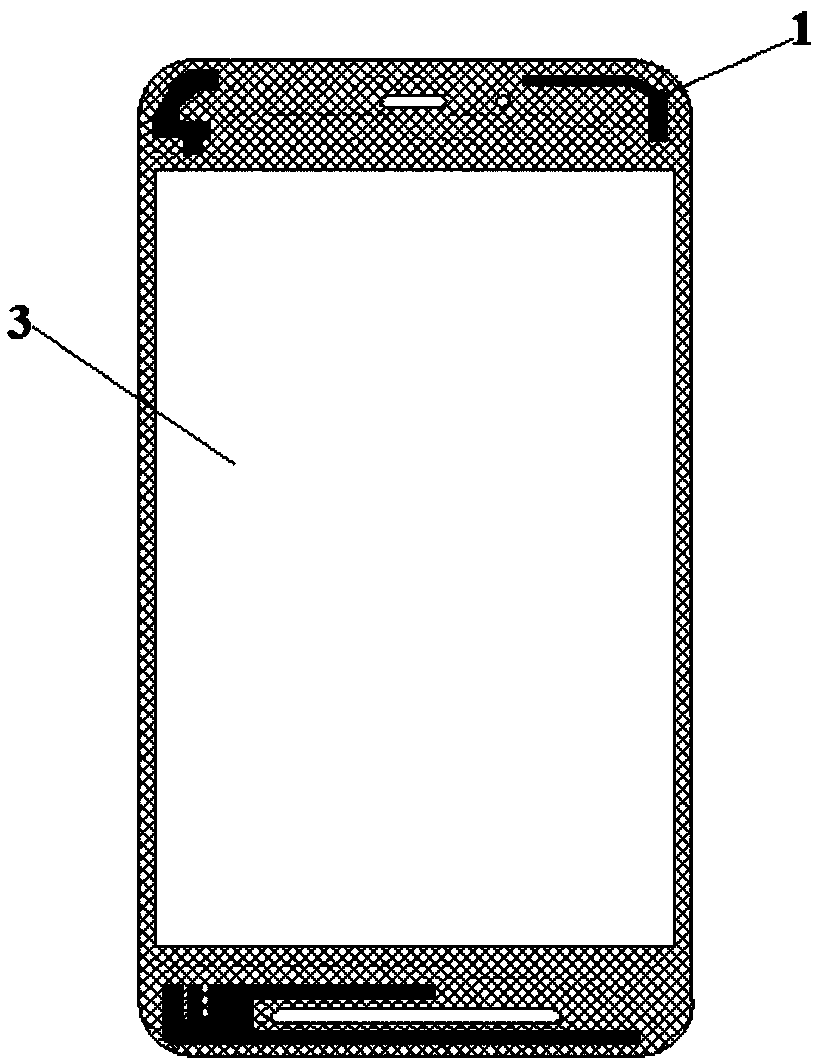

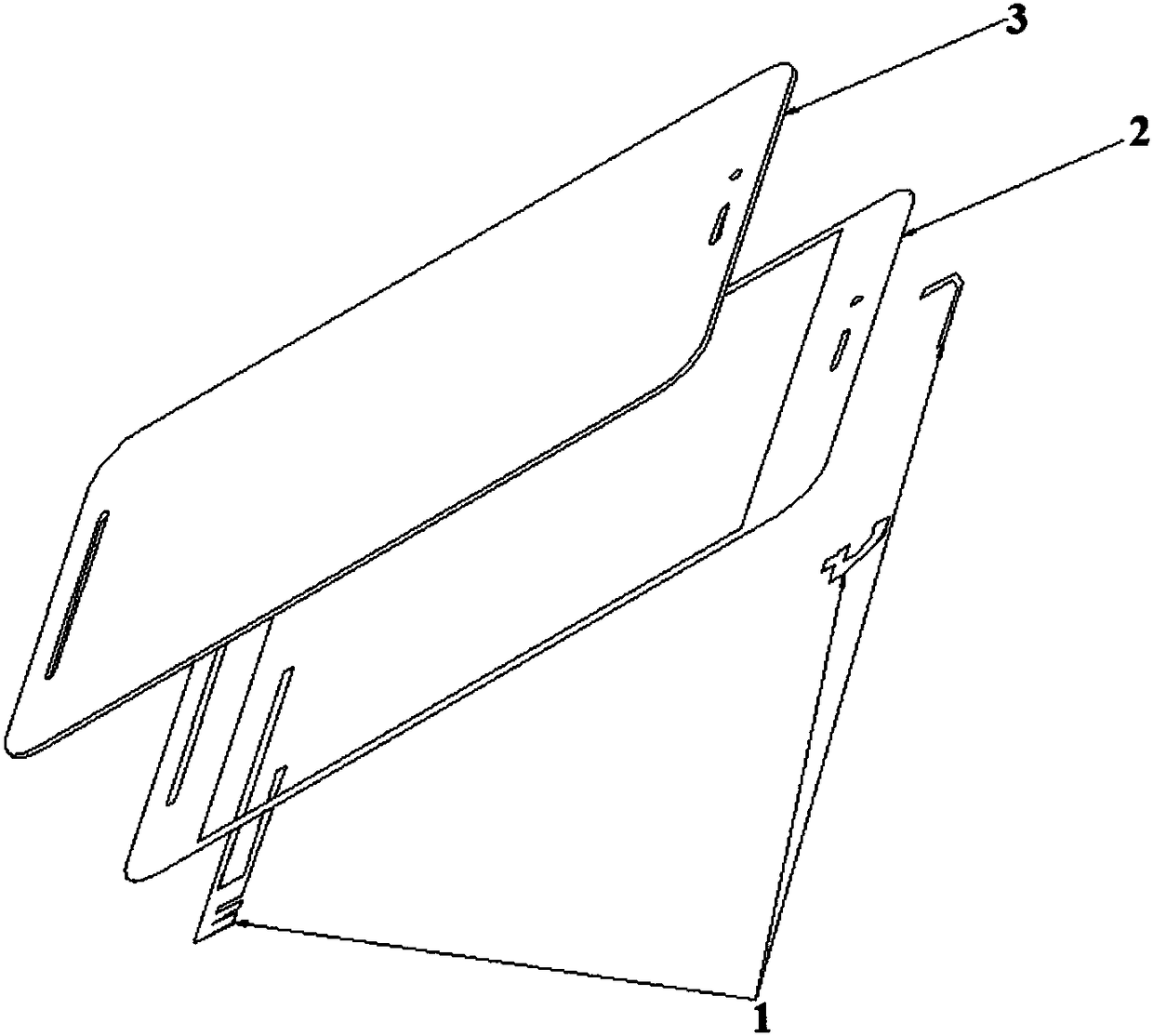

[0046] (2) Pad-print the corresponding built-in antenna 1 circuit onto the glass carrier 3 (PS: the product is a touch screen At this moment, masking ink 2 has been attached to the transparent glass carrier 3);

[0047] (3) Dry at 150°C.

[0048] The adhesive ink with strong adhesive force adopted in the above steps comprises the following components in parts by weight: 35 parts of basic resin acrylic resin (Acryl resin); 10 parts of auxiliary resin isocyanate resin (Isocyanate resin); 1.2 parts of adhesive; 1.2 parts of thickener; 32 parts of organic solvent benzene. The above-mentioned bonding ink can be prepared by conventional methods. The following method can be used to prepare the raw materials according to the above ratio, then mix the raw materials, stir and mix them uniformly a...

Embodiment 2

[0057] The antenna manufacturing method based on the PDS process in this embodiment specifically includes the following steps:

[0058] (1) Prepare a bonding ink with strong adhesion;

[0059] (2) Screen-print the corresponding built-in antenna 1 circuit onto the glass carrier 3 (PS: the product is a touch screen At this moment, masking ink 2 has been attached to the transparent glass carrier 3);

[0060] (3) Dry at 120°C.

[0061] The reliability test result is consistent with Example 1; the cost advantage is equivalent to that of Example 1, and more ink will be wasted relative to pad printing; the ink with strong adhesion used in the above steps is consistent with Example 1.

Embodiment 3

[0063] The antenna manufacturing method based on the PDS process in this embodiment specifically includes the following steps:

[0064] (1) Prepare a bonding ink with strong adhesion;

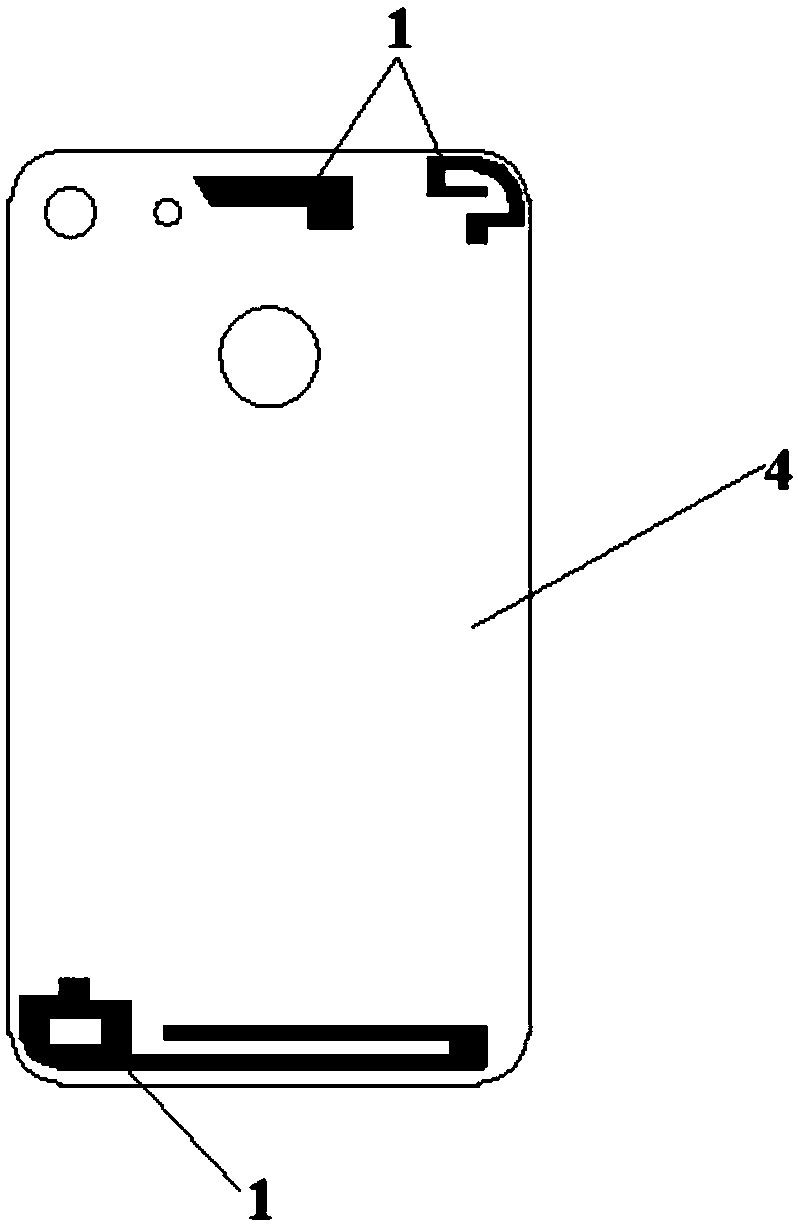

[0065] (2) Print the corresponding built-in antenna 1 circuit on the ceramic back cover 4 (such as Figure 3-4 shown);

[0066] (3) Dry at 160°C.

[0067] The adhesive ink with strong adhesion used in the above steps includes the following components in parts by weight: 36 parts of basic resin acrylic resin (Acryl resin); 9 parts of auxiliary resin isocyanate resin (Isocyanate resin); 1.3 parts of adhesive; 1.4 parts of thickener; 31 parts of organic solvent benzene. The above-mentioned bonding ink can be prepared by conventional methods. The following method can be used to prepare the raw materials according to the above ratio, then mix the raw materials, stir and mix them uniformly at a high speed, and then grind to make the fineness below 15um to obtain the adhesive ink with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com