Control device for 3D printer

A technology of 3D printers and control devices, applied in printing devices, computer control, general control systems, etc., can solve the problems of increased waste, environmental pollution, and threats to people's health, and achieve the effect of easy printing and use, and increased waste prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Referring now to the accompanying drawings, a description will be given in detail of the exemplary embodiments. For brief description with reference to the drawings, the same or equivalent components will be provided with the same reference numerals, and descriptions thereof will not be repeated.

[0048] The 3D printers described in this disclosure are not limited to methods for producing objects. For example, a method for printing a 3D object by using layer-by-layer jetting of a liquid photocurable or thermoset material and then ultraviolet (UV) curing of the liquid photocure or thermoset material, a method for printing a thermoplastic by heating and melting it into a semi-liquid state and Then a method of extruding the thermoplastic to form a 3D object, a method for forming a 3D object by spraying and solidifying material in the form of thin lines or powder, etc. are driven to be applied to the 3D printer of the present disclosure.

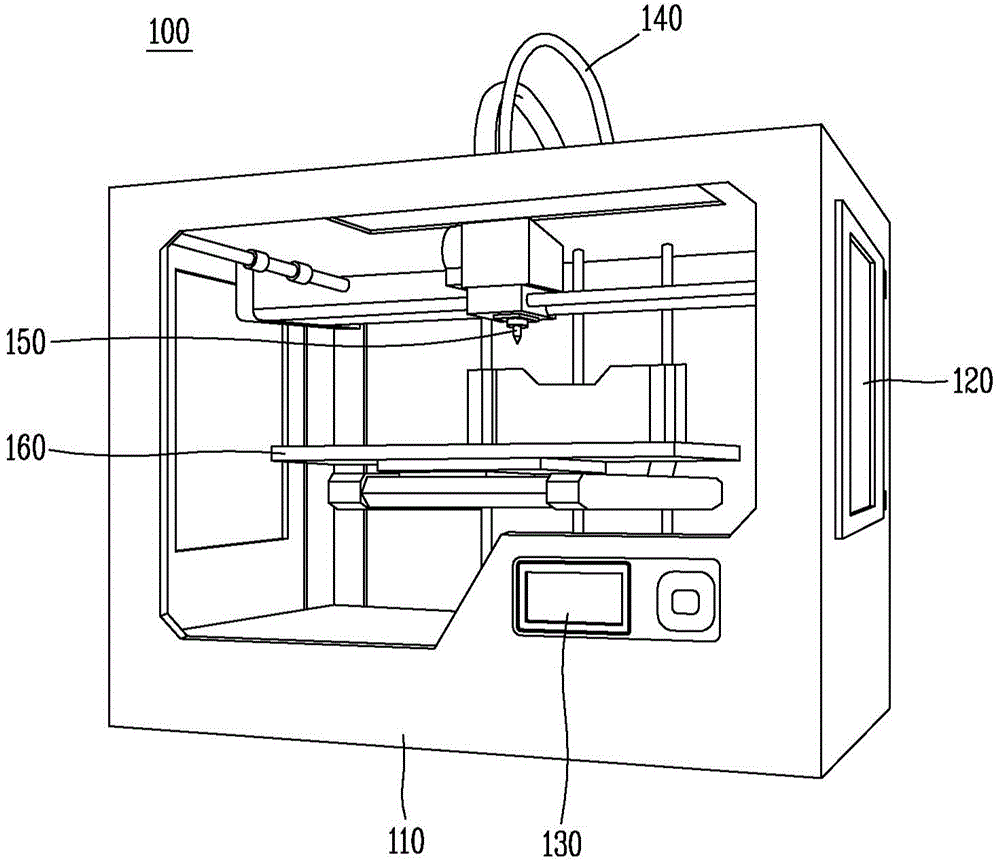

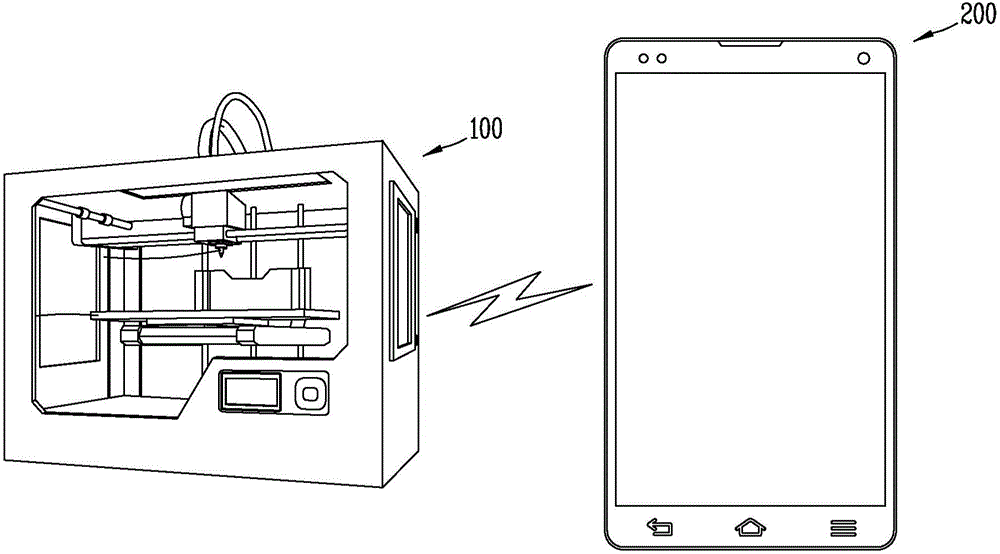

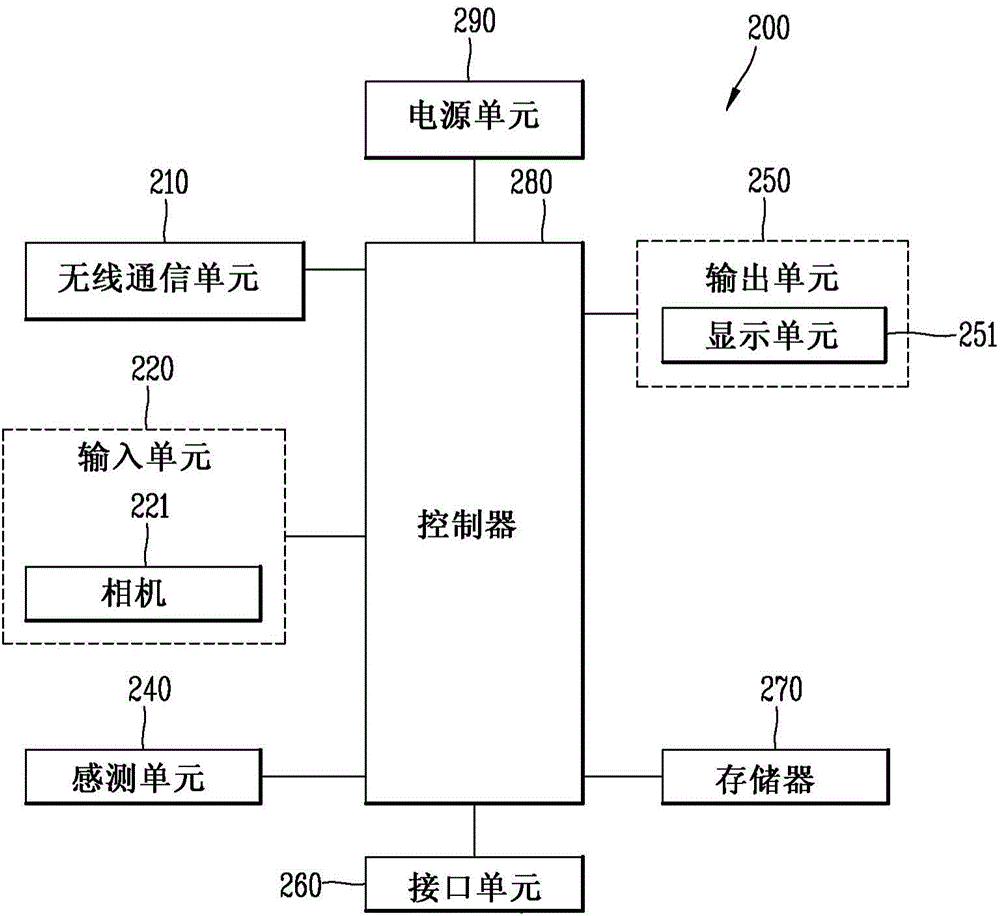

[0049] Figure 1A is a conceptua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com