Printing method for realizing vignetting effectof automobile instrument dial

A technology of automobile instrumentation and printing method, applied in screen printing method, optics, instruments, etc., can solve the problems of not meeting the needs of automobile development, not producing halo effects, etc., achieving low cost, short time period, and adjusting data. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

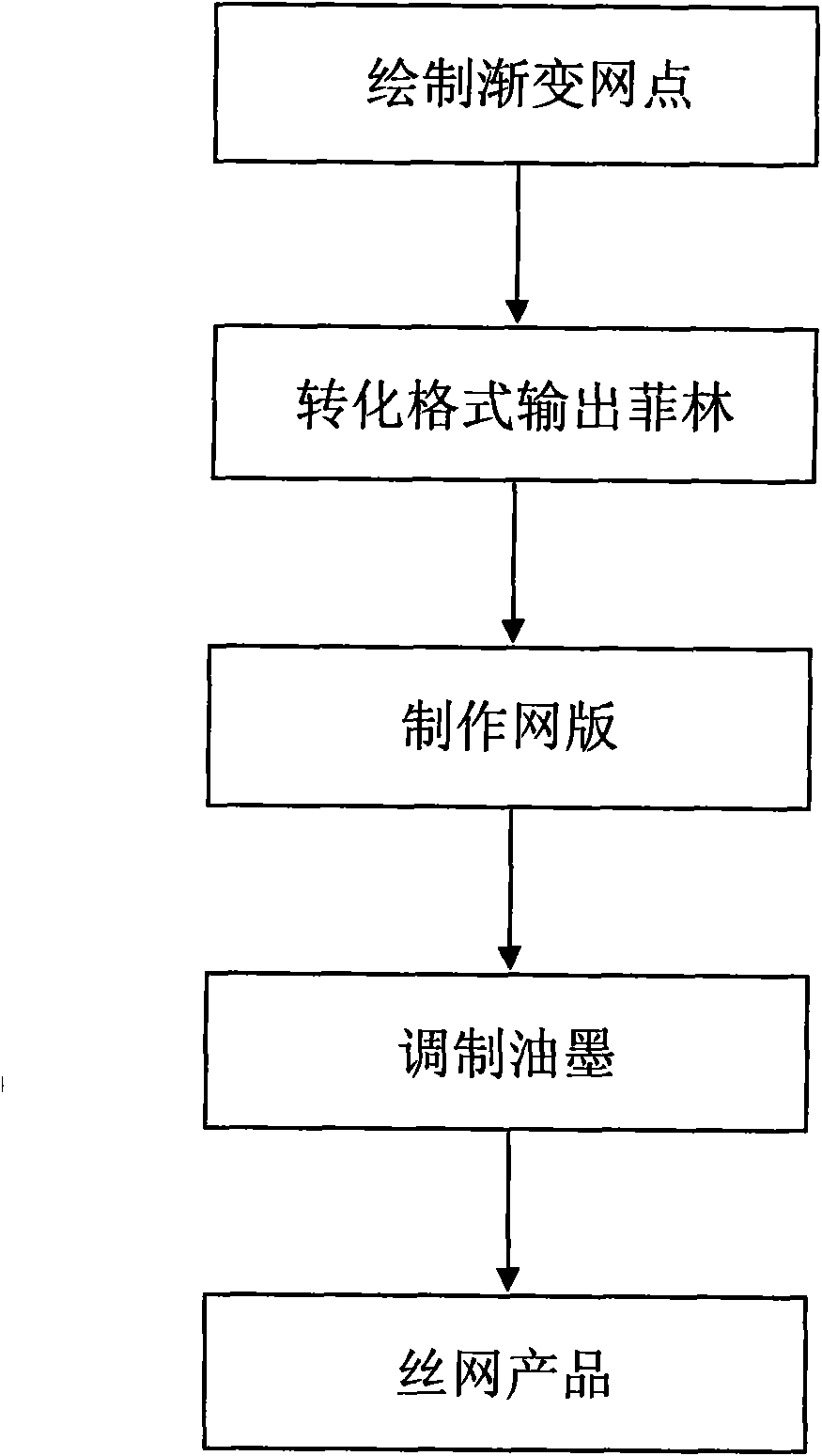

[0051] use as figure 1 Shown flow process, the halo printing method of the dial of the automobile instrument of the present invention comprises the following steps:

[0052] (1) Draw circular dots with gradient sizes in engineering drawing software:

[0053] (a) In the engineering drawing software AUTOCAD, first determine the position of the area where the halo effect of the dial is produced;

[0054] (b) In the software, the inner ring is drawn with circular uniformly distributed small dots. After several trial productions, it is determined that the minimum printing dot diameter for screen printing is 0.20mm;

[0055] (c) In the software, the distance between dots drawn on the same circle is 0.9mm, and the distance between adjacent inner and outer rings is 0.5mm;

[0056] (d) Based on the inner ring, the diameter of the dot increases by 0.4mm for each outer circle, and the circle dot design is completed;

[0057] (2) After converting it into a graphic design software forma...

Embodiment 2

[0073] use as figure 1 Shown flow process, the halo printing method of the dial of the automobile instrument of the present invention comprises the following steps:

[0074] (1) Draw circular dots with gradient sizes in engineering drawing software:

[0075] (a) In the engineering drawing software AUTOCAD, first determine the position of the area where the halo effect of the dial is produced;

[0076] (b) In the software, the inner ring is drawn with circular uniformly distributed small dots. After several trial productions, it is determined that the minimum printing dot diameter for screen printing is 0.25mm;

[0077] (c) In the software, the distance between dots drawn on the same circle is 1mm, and the distance between adjacent inner and outer circles is 0.6mm;

[0078] (d) Based on the inner ring, the diameter of the dot increases by 0.6mm for each outer circle, and the circle dot design is completed;

[0079] (2) After converting it into a graphic design software forma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com