Integral annular three-dimensional fabric and weaving method thereof

A three-dimensional fabric and integral technology, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of difficult three-dimensional circular fabrics to be completely integrally formed, reduce production efficiency, increase processes, etc., to achieve easy industrialization and use, and inhibit fabric delamination , The effect of low weaving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

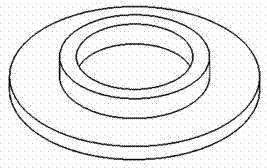

[0051] Weaving flanged circular fabric with "T" section.

[0052] The yarn 1 in the xoy plane of the endless fabric includes yarns in two directions of the x-direction yarn 11 and the y-direction yarn 12, and the cross-section is "T". Both the x-direction yarn 11 and the y-direction yarn 12 are 190tex quartz fiber×3 strands, and the z-direction yarn 2 is 190tex quartz fiber×1 strand. According to the cross-sectional shape, the fabric is divided into two parts: the outer ring E (indicated by ○ in Figure 4) and the inner ring F (indicated by ● in Figure 4). The number of yarn layers of the x-direction yarn 11 of the outer ring E part is 10 layers, the number of yarn layers of the y-direction yarn 12 is 11 layers, and the total thickness is 1 cm; the yarn of the x-direction yarn 11 of the inner ring F part The number of thread layers is 25 layers, the number of yarn layers of y-direction yarn 12 is 26 layers, and the total thickness is 2.5 cm. The arrangement density of the yar...

Embodiment 2

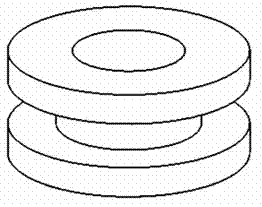

[0065] Weaving flange-type three-dimensional fabric with "I" cross-section.

[0066] The yarn 1 in the xoy plane of the flange type annular fabric includes yarns in four directions: x-direction yarn 11, y-direction yarn 12, +45°-direction yarn 13 and -45°-direction yarn 14, the cross-section For the "work" type. The yarn 1 in the xoy plane is 12K T300 carbon fiber, and the z-direction yarn 2 is 6K T300 carbon fiber. According to the cross-sectional shape, the fabric is divided into two parts, an outer ring E and an inner ring F, as in Example 1, wherein the outer ring E is composed of an upper part and a lower part. The number of yarn layers of the x-direction yarn 11, +45°-direction yarn 13 and -45°-direction yarn 14 of the upper and lower parts of the outer ring E is 5 layers, and the number of yarn layers of the y-direction yarn 12 It is 6 layers, and the thickness of each part is 1.1 cm; the number of yarn layers of the x-direction yarn 11, +45°-direction yarn 13 and -45...

Embodiment 3

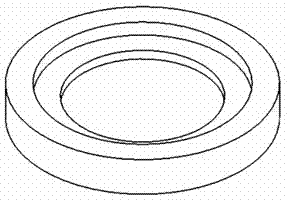

[0082] to weave Shaped cross-section reinforced ring loop fabric.

[0083] The yarn 1 in the xoy plane of the reinforced ring type annular fabric includes yarns in two directions of the x-direction yarn 11 and the y-direction yarn 12, and the cross section is type. The yarn 1 in the xoy plane is 12K T300 carbon fiber, and the z-direction yarn 2 is 6K T300 carbon fiber. The number of yarn layers of the x-direction yarn 11 of the outer ring E part is 38 layers, the number of yarn layers of the y-direction yarn 12 is 39 layers, and the total thickness is 4 cm; the x-direction yarn 11 of the inner ring F part The number of yarn layers is 18, the number of yarn layers of the y-direction yarn 12 is 19 layers, and the total thickness is 2 cm. The fabric outer ring E is 20 cm in diameter and the inner ring F is 12 cm in diameter.

[0084] Steel pipe arrangement process parameter design:

[0085] (1) The length of the steel pipe in the E part of the outer ring L1=15cm

[0086] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com