Jacquard-like high-figured fabric and method for weaving fabric on dobby machine

A dobby and fabric technology, which is applied in the direction of dobby, dredging fabrics, fabrics, etc., can solve the problems of limited variation, high equipment cost, limited pattern expansion, etc., and achieves the effect of strong randomness and reduced weaving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

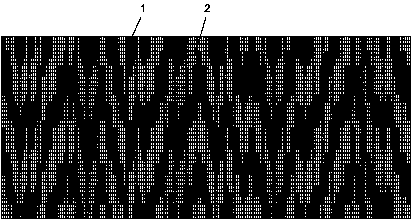

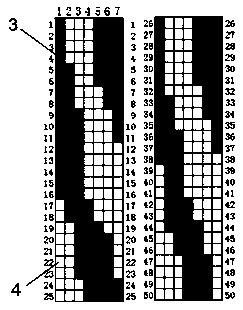

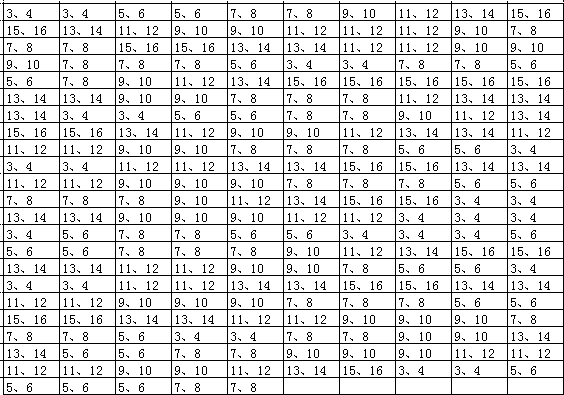

[0049] The imitation jacquard high pattern fabric of the present invention is formed by interweaving one set of warp threads and two sets of weft threads, forming a broken line pattern pattern along the width direction, and the width and fluctuation range of the broken lines are constantly changing, and the broken lines are continuously distributed along the width direction , without interruption; the high-shrinkage yarn is 140D / 48F polyester elastic yarn with a dry heat shrinkage rate of 30%, and the low-shrinkage yarn is 40 double-ply cotton yarns with a dry heat shrinkage rate of less than 3%; the fabric includes flower part 1 and ground Part 2, the surface tissue of the flower part 1 is formed by interweaving the warp threads of 40 double-ply cotton yarns and the weft threads of 40 double-ply cotton yarns, and the inner layer tissue is the weft floating length formed by elastic yarn; the ground part 2 is composed of warp threads and two The weft threads interweave to form a...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the order of arrangement of the seven basic patterns is different, and the order of drawing in healds is different. Figure 5 Shown; high-shrinkage yarn is 100% polypropylene elastic yarn of 140D / 48F with dry heat shrinkage rate of 45%, and low-shrinkage yarn is 40 double-ply cotton-linen blended yarns with dry heat shrinkage rate lower than 3%; other steps With embodiment 1, the fabric pattern effect that forms is as follows Figure 6 Shown, fabric warp thread and weft thread density are the same as embodiment 1.

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that the seven basic patterns and their arrangement order are different. The number of basic tissues of the flower part and the ground part in each basic pattern is 6~10, and the high shrinkage yarn is the dry heat shrinkage rate It is 100% nylon elastic yarn of 15% 140D / 48F, and the low-shrinkage yarn is 40 double-ply hemp yarns with a dry heat shrinkage rate lower than 3%; the basic pattern is as follows Figure 7 As shown, the arrangement order of the basic patterns is different, and the drawing order is different. Figure 8 Shown, other steps are the same as embodiment 1, and the fabric pattern effect that forms is as follows Figure 9 Shown, fabric warp thread and weft thread density are the same as embodiment 1.

[0063] Fabrics with different patterns can be prepared by changing the order of the seven basic patterns, and the width and degree of fluctuation of the zigzag pattern of the fabric are changed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dry heat shrinkage | aaaaa | aaaaa |

| Dry heat shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com