Ring spinning elastic weft with high elongation and production process of ring spinning elastic weft

A production process, ring spinning technology, applied in the field of spinning, to achieve the effects of good heat resistance, less weft stop, less loss of strength and extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

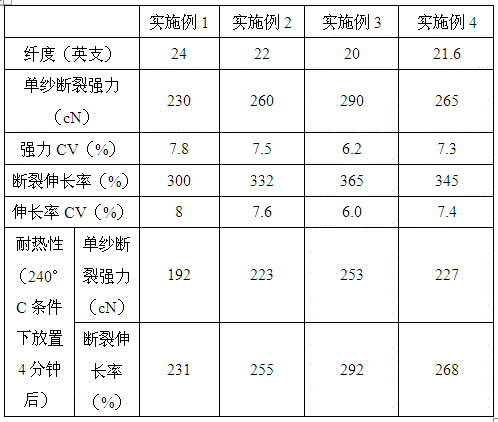

Embodiment 1

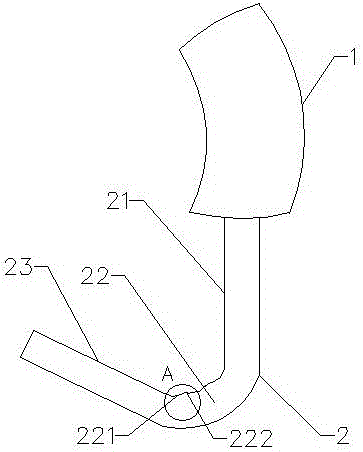

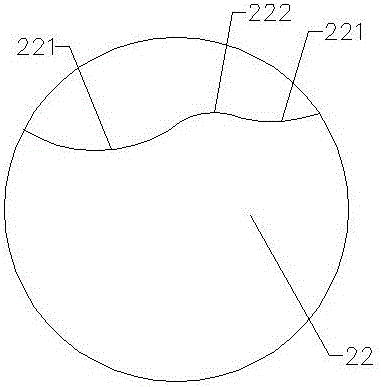

[0047] Embodiment 1 A kind of production technology of ring spinning high elongation elastic weft yarn

[0048] The ring-spinning spinning frame is modified, and the hanging wire frame and the wire guide wheel are installed, and the cotton fiber is covered on the outside of PA66UDY. The outsourcing cotton passes through the roving, and is drafted by the roller to make a beard. Through the twisting system of the spinning frame, the cotton fiber is tightly and evenly wound on the outer layer of PA66UDY, and wound on the bobbin to make a spun bobbin. After the bobbin is twisted and twisted, it is processed by an automatic winding machine Cone shape.

[0049] Specifically include the following steps:

[0050] Step 1. Preparation of PA66 undrawn yarn

[0051] The preparation of described PA66 unstretched silk, comprises the following steps:

[0052] Include the following steps:

[0053] (1) Raw material selection

[0054] Use PA66 resin, slice viscosity 2.65-3.1;

[0055] The...

Embodiment 2

[0108] Embodiment 2 A kind of production technology of ring spinning high elongation elastic weft yarn

[0109] Specifically include the following steps:

[0110] Step 1. Preparation of PA66 undrawn yarn

[0111] The preparation method is the same as in Example 1, only the following steps are changed:

[0112] (2) Modification

[0113] The mass ratio of the total mass of the potassium iodide liquid and the copper acetate liquid to the PA66 resin is 1:300.

[0114] (6) Spinning, cooling and forming

[0115] Component preheating temperature: 320°C, metering pump specification: 2.4ml / r×2, metering pump speed: 18 rpm, side blowing wind speed 1.3 m / s, side blowing wind temperature: 25°C, rheumatism 70%.

[0116] (7) Winding

[0117] The filaments are cooled and formed by side blowing and enter the winding machine through the interlayer heat pipe tunnel;

[0118] Upper godet frequency: 70HZ, lower godet frequency: 70HZ, friction roller frequency: 70HZ, reciprocating traverse f...

Embodiment 3

[0142] Embodiment 3 A production process of ring spinning high elongation elastic weft yarn

[0143] Specifically include the following steps:

[0144] Step 1. Preparation of PA66 undrawn yarn

[0145] The preparation method is the same as in Example 1, only the following steps are changed:

[0146] (2) Modification

[0147] The mass ratio of the total mass of the potassium iodide liquid and the copper acetate liquid to the PA66 resin is: 1:700.

[0148] (6) Spinning, cooling and forming

[0149] Component preheating temperature: 323°C, metering pump specification: 2.4ml / r×2, metering pump speed: 18.2 rpm, side blowing wind speed 1.34 m / s, side blowing wind temperature: 26°C, rheumatism 75%.

[0150] (7) Winding

[0151] The filaments are cooled and formed by side blowing and enter the winding machine through the interlayer heat pipe tunnel;

[0152] Upper godet frequency: 72HZ, lower godet frequency: 72HZ, friction roller frequency: 71HZ, reciprocating traverse frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com