Ultrahigh molecular weight polyethylene fiber flat wire and preparation method thereof

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the direction of single-component polyolefin rayon, fiber treatment, wet spinning, etc., can solve the problems of limited application, achieve the goal of reducing consumption, reducing cost, and shortening the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The molecular weight is 1.5×10 7 g / mol ultra-high molecular weight polyethylene powder and a certain amount of decahydronaphthalene to prepare a mixed solution with a mass concentration of ultra-high molecular weight polyethylene of 10%, and add hindered phenolic antioxidant 1010 and organic water-soluble lubricant 2 -Methyl dodecanoic acid, the contents are respectively 5% and 10% of the quality of ultra-high molecular weight polyethylene to obtain a suspension mixture;

[0047] (2) Heat and swell the suspension mixture obtained in step (1) at 130°C for 10 minutes, inject the swollen and uniformly dispersed suspension mixture into a twin-screw extruder and extrude, extrude the jelly-like filaments at the die through air and The primary jelly fibers are formed after two stages of cooling in the water bath;

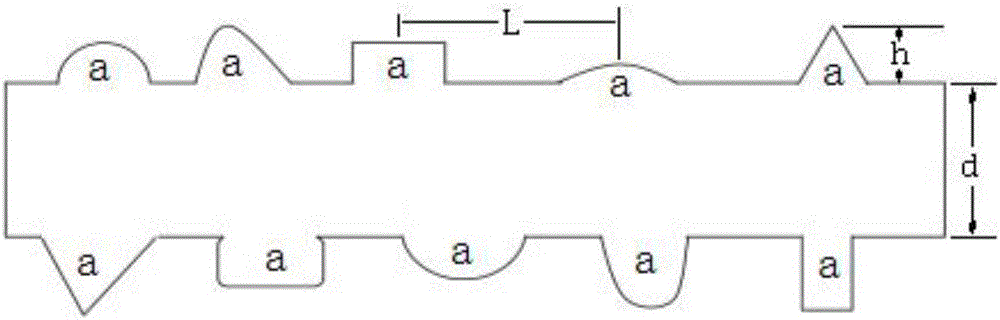

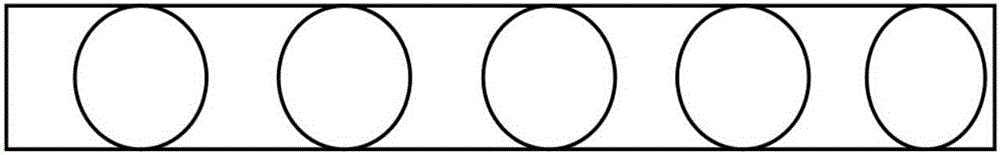

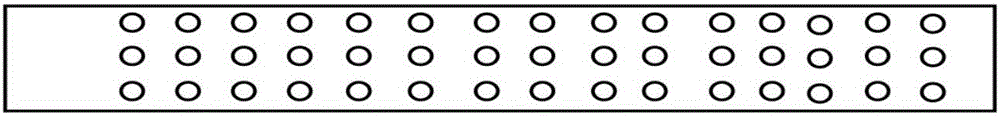

[0048] (3) Two-roll primary pressing with special pressure rollers made of corrosion-resistant metal substrates. The rollers are located in the air cooled by a...

Embodiment 2

[0051] (1) The molecular weight is 3.0×10 7 g / mol ultra-high molecular weight polyethylene powder and a certain amount of paraffin oil to prepare a mixed solution with a mass concentration of ultra-high molecular weight polyethylene of 5%, and add phosphite antioxidant 618 and sodium chloride, the contents are respectively 1% and 15% of the quality of ultra-high molecular weight polyethylene to obtain a suspension mixture;

[0052] (2) Heat and swell the suspension mixture obtained in step (1) at 120°C for 10 minutes, inject the swollen and evenly dispersed suspension mixture into a twin-screw extruder for extrusion, and extrude the jelly-like filaments at the die through air and The primary jelly fibers are formed after two stages of cooling in the water bath;

[0053] (3) Multi-roller 3-stage pressing with special pressure rollers made of silicone rubber substrates, the rollers are located in the air cooled by a water bath, the diameter of the rollers is 20cm, the temperatu...

Embodiment 3

[0056] (1) The molecular weight is 4.5×10 7 g / mol ultra-high molecular weight polyethylene powder and a certain amount of mineral oil are formulated into a mixed solution with a mass concentration of ultra-high molecular weight polyethylene of 15%, and sulfur-based antioxidants 1035 and 1-allyl-3- Methylimidazolium chloride salt ionic liquid, the content of which is 2% and 1% of the mass of ultra-high molecular weight polyethylene, respectively, to obtain a suspension mixture;

[0057] (2) Heat and swell the suspension mixture obtained in step (1) at 110°C for 10 minutes, inject the swollen and uniformly dispersed suspension mixture into a twin-screw extruder and extrude, extrude the jelly-like filaments at the die through air and The primary jelly fibers are formed after two stages of cooling in the water bath;

[0058] (3) Using engineering plastic (such as PC) base material special pressure roller with single roller and flat plate and double roller composite 5-stage pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com