Multi-section acid leaching, washing and pressure filtration metal extraction process and integrated device thereof

A technology of metal extraction and acid leaching, which is applied in the direction of improving process efficiency and can solve problems such as insufficient washing of slag, broken slag filter cake, and inability to wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

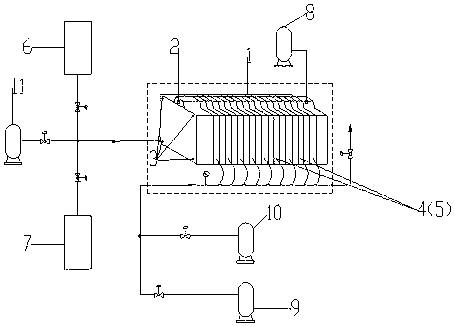

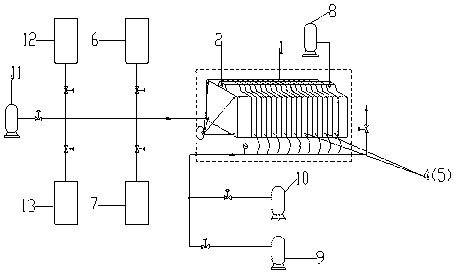

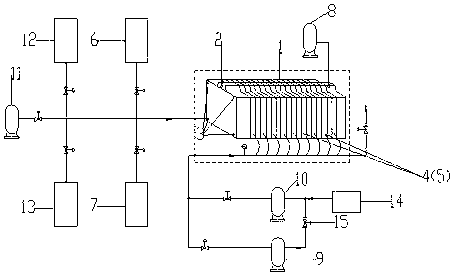

Image

Examples

Embodiment 1

[0046] The multi-stage acid leaching, washing and pressure filtration process described in this embodiment comprises the following steps,

[0047] (1) Inject the manganese acid leaching solution obtained by a section of acid leaching into the filter chamber of the diaphragm filter press at a pressure of 0.2 MPa, and the filtrate flows out along the filtrate channel to obtain a 5t filter cake, and pre-press the filter cake with a pre-pressing pressure of 0.2 MPa;

[0048] (2) In the pre-pressed state, inject 1.5t, 7v% sulfuric acid into the filter chamber at a pressure of 0.2MPa to carry out two-stage acid leaching of the filter cake, and the time for the second-stage acid leaching is 5 minutes;

[0049] (3) After the second-stage acid leaching is completed, keep the pre-compressed state, and the water will be 3 The flow rate of / h is continuously injected into the filter chamber for a period of washing, and the period of washing for a period of time is 120min;

[0050] (4) A...

Embodiment 2

[0054] The multi-stage acid leaching, washing and pressure filtration process described in this embodiment comprises the following steps,

[0055] (1) Inject the manganese acid leaching solution obtained by a section of acid leaching into the filter chamber of the diaphragm filter press at a pressure of 0.6 MPa, and the filtrate flows out along the filtrate channel to obtain a 4t filter cake, and the filter cake is pre-pressed, and the pre-pressing pressure is 0.6 MPa;

[0056] (2) In the pre-pressed state, inject 8t of 70°C hydrochloric acid with a concentration of 6v% into the filter chamber at a pressure of 0.6MPa to perform two-stage acid leaching on the filter cake, and the time for the second-stage acid leaching is 120min ;

[0057] (3) After the second-stage acid leaching is completed, keep the pre-compressed state, and water at 70°C with a pressure of 0.6MPa and a pressure of 20m 3 The flow rate of / h is continuously injected into the filter chamber for a period of w...

Embodiment 3

[0062] The multi-stage acid leaching, washing and pressure filtration process described in this embodiment comprises the following steps,

[0063] (1) Fill the manganese acid leaching solution obtained by a section of acid leaching into the filter chamber of the diaphragm filter press at a pressure of 0.5 MPa, and the filtrate flows out along the filtrate channel to obtain a 5t filter cake, and pre-press the filter cake, and the pre-compression pressure 0.4MPa;

[0064] (2) In the pre-pressed state, inject 5t of phosphoric acid at 50°C with a concentration of 5v% into the filter chamber at a pressure of 0.4MPa to perform two-stage acid leaching on the filter cake, and the time for the second-stage acid leaching is 100min ;

[0065] (3) After the second-stage acid leaching is completed, keep the pre-compressed state, and water at 50°C with a pressure of 0.5MPa and a pressure of 15m 3 The flow rate of / h is continuously injected into the filter chamber for a period of washing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com