Method for clarifying green tea extract liquid

A green tea extract, green tea technology, applied in tea extraction, tea, food science and other directions, can solve problems such as product yield, quality impact, etc., achieve the effects of good clarity, easy industrialization and application, and less equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 The preparation method of green tea extract of the present invention

[0025] Take green tea powder, add 20 times the amount of 50% ethanol, extract twice at 80°C for 0.5 hours each time, filter, combine the filtrates, recover the ethanol under reduced pressure until there is no alcohol smell, and use the alcohol extract for later use; weigh ZTC1+1II Type A clarifier, add deionized water, swell, stir, and prepare 1% viscose solution; weigh ZTC1+1II type clarifier B component, add 1% acetic acid solution, swell, stir, and prepare 1% Viscose liquid; dilute the spare alcohol extract to the crude drug concentration of 1:20 crude drug volume ratio, at 80°C, stir and disperse the B component (ZTC1+1II type clarifying agent purchased from Tianjin Zhengtiancheng Clarification Technology Co., Ltd.), then stirred once every 30min, and after 2h, the temperature of the medicinal solution was lowered to 60°C, and the A component (ZTC1+1II type clarifier) of 4% volume ...

Embodiment 2

[0026] Embodiment 2 The extraction method screening of green tea extract of the present invention

[0027] 1 Investigation of extraction solvent

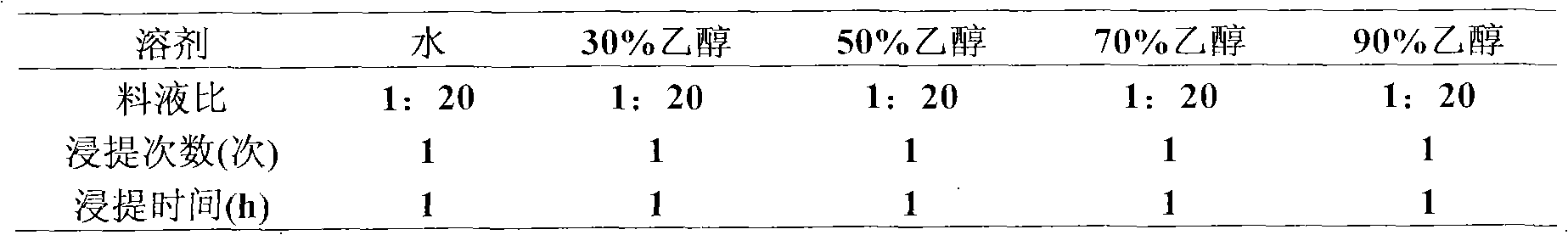

[0028] Tea polyphenols are easily soluble in water, ethanol, methanol, acetone, ethyl acetate and other solvents. In this experiment, the content of tea polyphenols (GB / T8313-2002) was used as the evaluation index to investigate the effects of water and different concentrations of ethanol on tea polyphenols. Extraction efficiency, screening the best extraction solvent. See Table 1:

[0029] Table 1 Extraction solution, selection of extraction parameters

[0030]

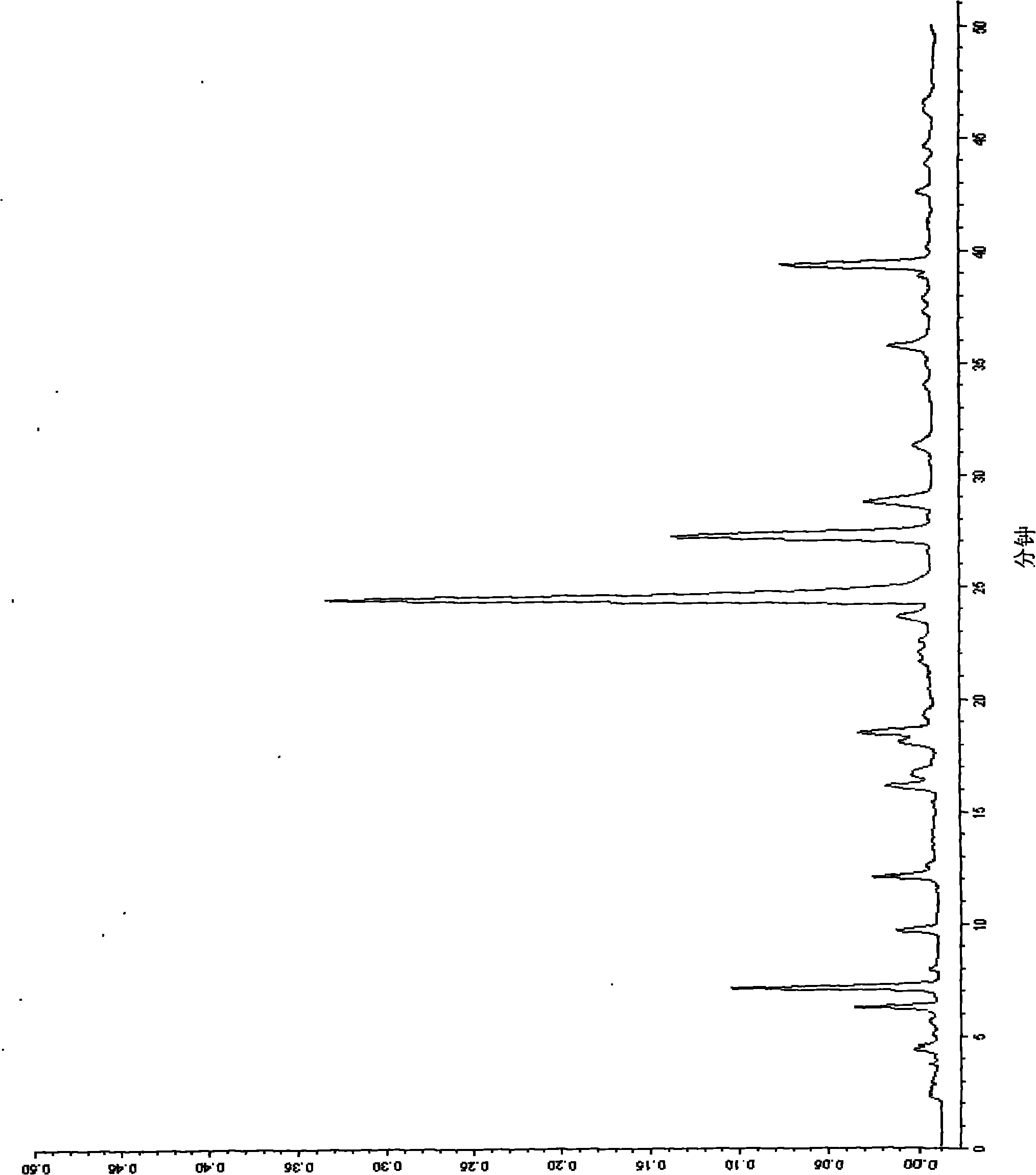

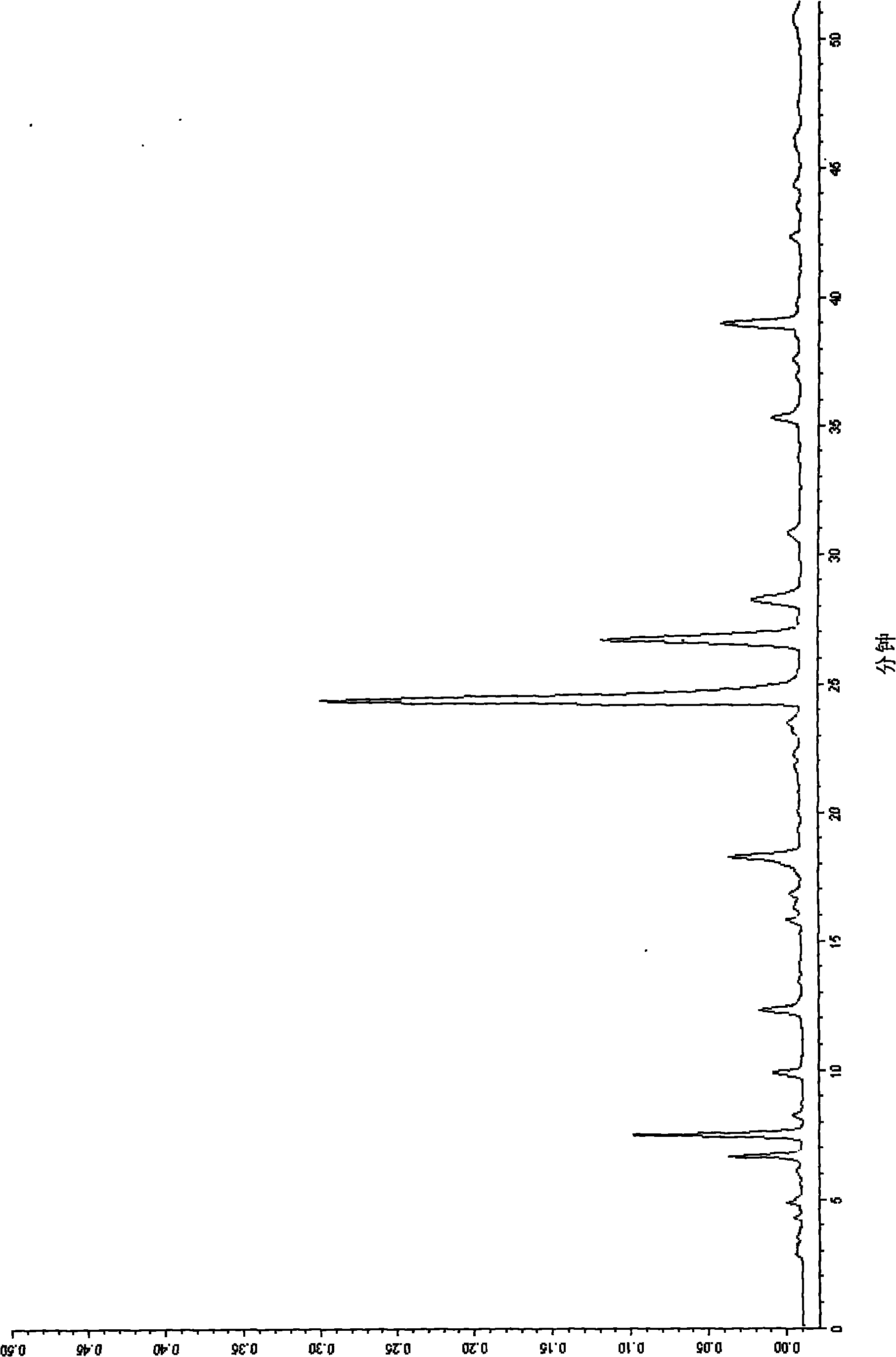

[0031] Table 2 Results of extraction solution

[0032]

[0033] From the above results, combined with actual production, it is determined that 50% ethanol is the extraction solvent. Judging from the color of the extract, when hot water extraction is used, tea polyphenols, especially catechins, are easily oxidized to form theaflavins and thearubigins, which may be...

Embodiment 3

[0065] Embodiment 3 The clarification method screening of green tea extract of the present invention

[0066] 1. Instruments and reagents:

[0067] Shimadzu LC 10-ATVP high performance liquid chromatograph; BP211D electronic balance (1 / 10,000, 1 / 100,000, Sartouris Co., Ltd., Germany); TL-500 desktop centrifuge (Shanghai Institute of Centrifugal Machinery); electronic Constant temperature water bath (Beijing Guohua Medical Instrument Factory); UV1100 ultraviolet-visible spectrophotometer (Shanghai Tianmei Scientific Instrument Co., Ltd.); ZTC1+1 II clarifier (Tianjin Zhengtiancheng Clarification Technology Co., Ltd.); methanol (HPLC grade) Acetonitrile (HPLC grade) was purchased from Tedia Corporation of the United States, and other reagents were of analytical grade.

[0068] EGC, EC, EGCG, ECG reference substance (purchased from Chengdu Master Company) (EGCG: epigallocatechin gallate; ECG: epicatechin gallate; EGC: epigallocatechin; EC: epicatechin)

[0069] 2. Methods and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com