Process for preparing 1,1,2 trichloroethylane

A technology of trichloroethane and vinyl chloride, applied in the direction of halogen addition preparation, organic chemistry, etc., can solve the problems of reduced reaction selectivity, uneven temperature distribution, complicated production process, etc., and achieves convenient operation and simple equipment structure , Ease of promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

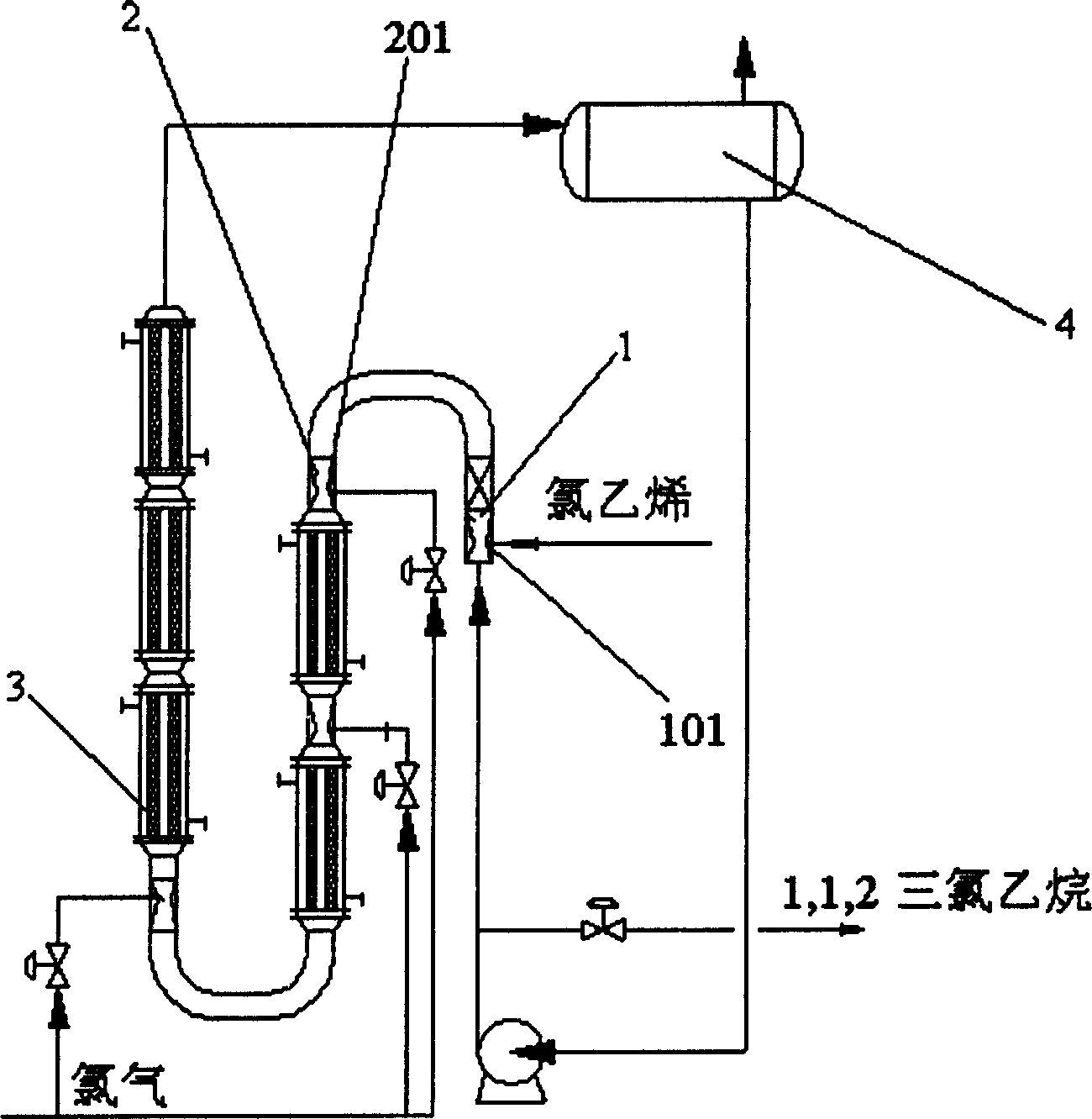

[0025] With 1,1,2 trichloroethane as the circulating medium, it is sent into the first mixing injection device 1, and vinyl chloride is sucked into the mixing area of the first mixing injection device 1 through the vinyl chloride inlet 101 of the first mixing injection device 1 , then 1,1,2 trichloroethane and vinyl chloride are sent into the second mixing injection device 2, chlorine gas is sucked into the mixing zone of the second mixing injection device 2 through the chlorine gas inlet 201 of the second mixing injection device 2, in In the mixing zone of the second mixing injection device 2, vinyl chloride and chlorine gas are mixed for pre-reaction, and then enter the main pipeline reactor 3 equipped with static mixing components for reaction to generate 1, 1, 2 trichloroethane, and the reacted product is , after flowing out from the main pipeline reactor 3 equipped with static mixing components, the unreacted gas is separated by the gas-liquid separator 4, and enters the...

Embodiment 2

[0036] Adopt the same flow process and method as embodiment 1, wherein:

[0037] Reaction process conditions

[0038] Feed amount of vinyl chloride: 8.3NM 3 / H

[0039] Chlorine feed rate: 8.9NM 3 / H

[0040] 1, 1, 2 trichloroethane liquid circulation volume: 6M 3 / H

[0041] Empty pipe liquid velocity: 0.85m / s

[0042] Dwell time: 7.1s

[0043] Reaction temperature: 50~55℃

[0044] Response result

[0045] 1,1,2 trichloroethane output: 48.5Kg / H (converted into 1,1,2 trichloroethane 100%wt) The conversion rate of vinyl chloride is greater than 99%, and the selectivity of vinyl chloride is greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com