Micro-nano tree-shaped solid oxide electrolytic-cell anode and preparation method thereof

A solid oxide, electrolytic cell technology, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as difficulty in adapting to high temperature, high current density operating conditions, reduced mechanical strength, etc., to expand the reactive area and improve the discharge rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of the anode of micro-nano dendritic solid oxide electrolytic cell provided by the present invention, the method comprises the following steps:

[0033] 1) Preparation of fluorite structure oxide slurry: add 1-5vol% Dow dispersant, 8-40vol% fluorite structure oxide powder in water, ultrasonically disperse evenly, and then add 1-10vol% of water volume Tao Binder and 1-5vol% magnesium aluminum silicate thickener, and finally ball milled for 2-5 hours to obtain a stable oxide slurry with fluorite structure;

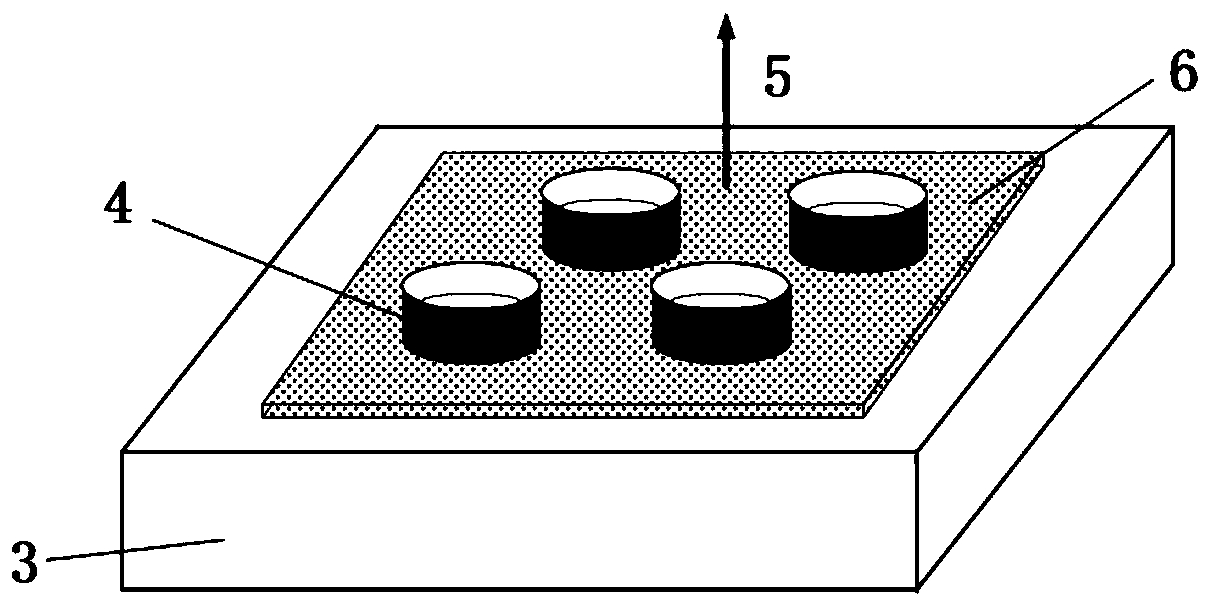

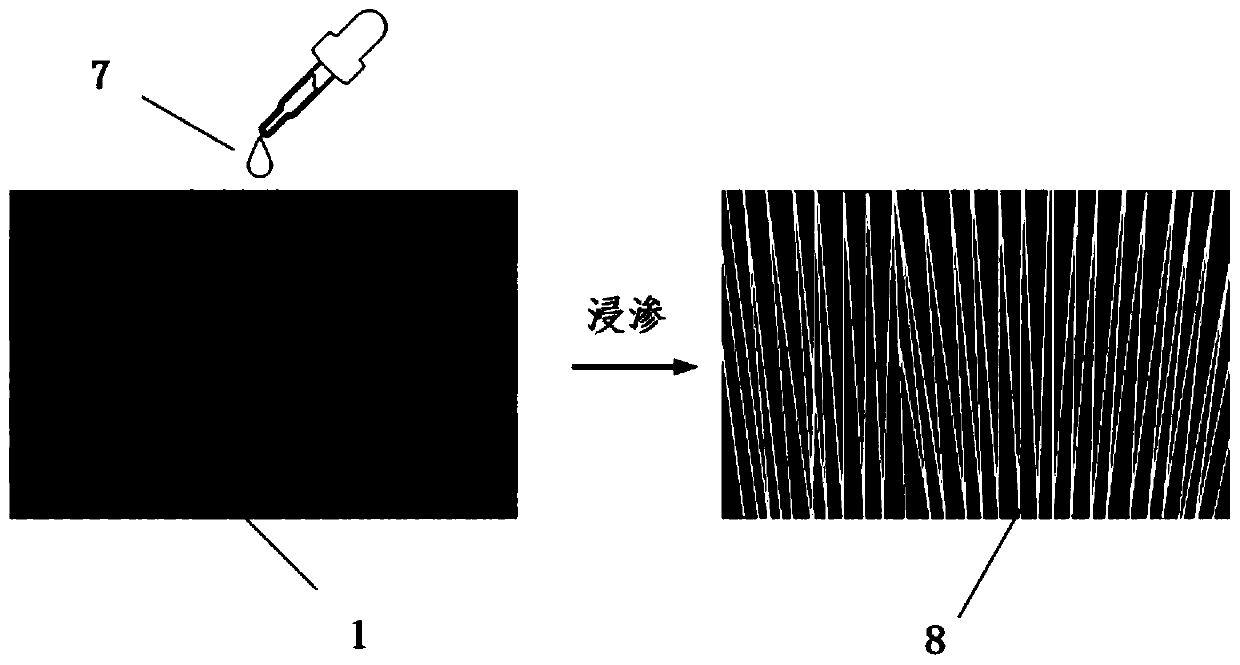

[0034] 2) Grouting: Place the polypropylene plastic mold on the metal copper plate, place the metal copper plate in a low-temperature constant temperature stirring reaction bath with a temperature of -20 to -196°C to freeze, inject the fluorite structure oxide slurry into the mold, and the ice crystals Grow upwards to form a tree, and freeze to shape after 10-60 minutes;

[0035]3) Drying: Demould the freeze-formed sample, transfer it to ...

Embodiment 1

[0041] 1) First add 1 vol% of Duchenne dispersant (DURAMAX D-3019) to the water, and after adjusting the pH=7, add 8 vol% of 8YSZ powder (Tosoh, Japan) to the water. After ultrasonic 20min, add 2vol% of Duchenne's binder (DURAMAX B-1000) and 2vol% of magnesium aluminum silicate thickener (Nanjing Hemingsi New Material Technology Co., Ltd.), then transfer to a ball mill (Faucus Experimental Instruments) Co., Ltd. produced F-P1000) in the ball mill for 2 hours to obtain a stable 8YSZ slurry;

[0042] 2) Grouting: place the metal plate in a low temperature and constant temperature stirring reaction bath (DHJF-4002 produced by Beijing Bokeruite Technology Co., Ltd.), fix the polypropylene plastic mold on the frozen metal copper plate, and pour 100 μL of step 1) The slurry is injected into the mold, and the slurry is frozen at -20°C;

[0043] 3) Freeze-drying: in step 2), the samples were demolded and transferred to a vacuum freeze-dryer (VS-802FD produced by Wuxi Woxin Instrument...

Embodiment 2

[0052] 1) First add 2% Duchenne dispersant (DURAMAX D-3019) to water, adjust pH=7, then add 15vol% 8YSZ powder (Tosoh, Japan). After ultrasonication for 30min, add 5vol% Duchenne binder (DURAMAX B-1000) and 5vol% magnesium aluminum silicate thickener (Nanjing Hemingsi New Material Technology Co., Ltd.), then transfer to a ball mill (Faucus Experimental Instruments) Co., Ltd. produced F-P1000) in the ball mill for 2 hours to obtain a stable 8YSZ slurry;

[0053] 2) Grouting: Fix the polypropylene plastic mold on the frozen metal copper plate, inject 200 μL of the slurry in step 1) into the mold, and freeze the slurry at -50°C;

[0054] 3) Freeze-drying: in step 2), the samples were demolded and transferred to a vacuum freeze-dryer (VS-802FD produced by Wuxi Woxin Instrument Manufacturing Co., Ltd.). After 24 hours of sufficient freeze-drying at -40°C, the ice crystals sublimate and leave highly tortuous channels, that is, the micron dendritic skeleton embryos are obtained;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com