Cylindrical lithium ion battery pre-charging method, production method and product obtained by production method

A lithium-ion battery, pre-charging technology, applied in secondary battery charging/discharging, final product manufacturing, non-aqueous electrolyte storage batteries, etc., can solve problems such as performance degradation, improve production quality, and promote more thorough effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

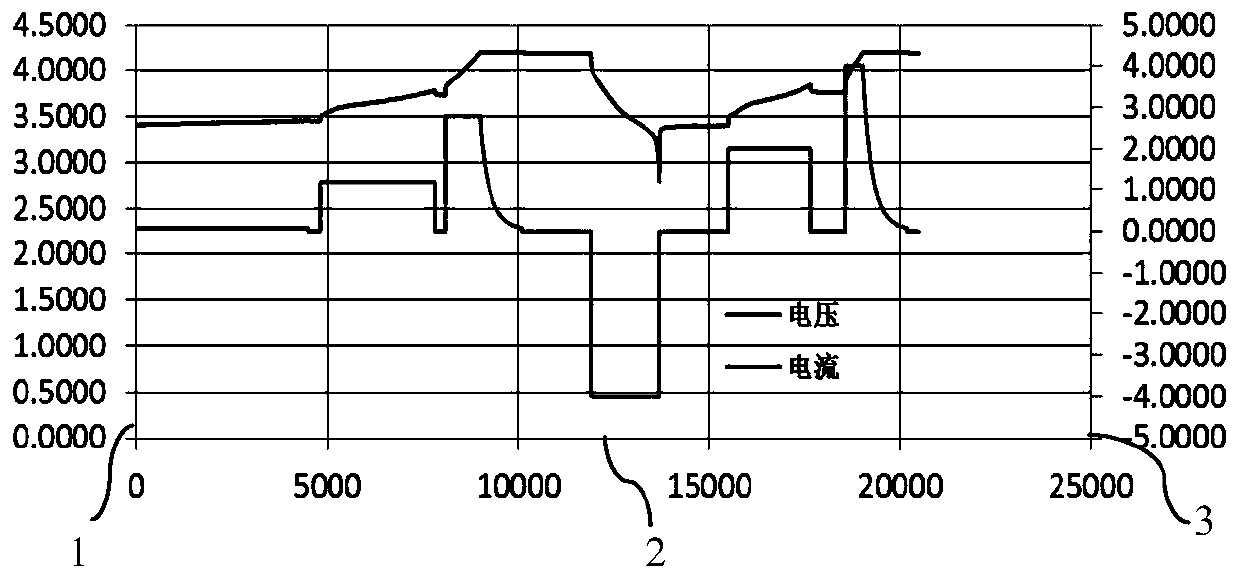

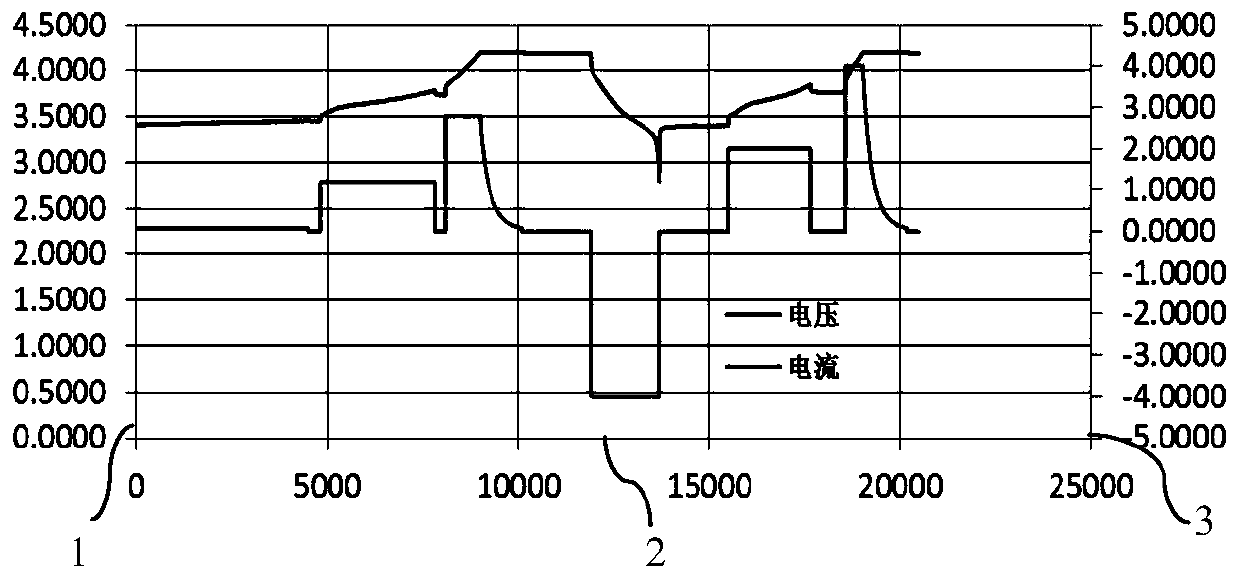

Image

Examples

Embodiment 1

[0033] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

[0034] A method for precharging a cylindrical lithium-ion battery in this embodiment specifically includes the following steps:

[0035] With nickel-cobalt lithium manganese oxide as the positive electrode and graphite as the negative electrode, the electrode assembly is made by winding with a diaphragm, put into a 18650 steel shell, and 1.3mol / L LiPF is injected into it 6 / (EC+PC+DEC) electrolyte, make battery 18650 battery, put it in a high-temperature vacuum heating box at 45°C, and evacuate to 200Pa, stand still for 48h; at 45°C high temperature, charge 5% at 0.05C for 30min , charge 55% at 0.5C for 60min, charge 100% at 0.6C for 20min; put it in a high-temperature vacuum heating box at 35°C, and evacuate to 40...

Embodiment 2

[0037] A method for precharging a cylindrical lithium-ion battery in this embodiment specifically includes the following steps:

[0038] With nickel-cobalt lithium manganese oxide as the positive electrode and graphite as the negative electrode, the electrode assembly is made by winding with a diaphragm, put into a 21700 steel shell, and 1.3mol / L LiPF is injected into it 6 / (EC+PC+DEC) electrolyte, make a battery 21700 battery, put it in a high-temperature vacuum heating box at 35°C, and evacuate to 100Pa, stand still for 48h; at room temperature at 25°C, charge 5% at 0.02C for 165min , charge 55% at 0.3C for 205min, charge 100% at 0.7C for 35min; put it in a high-temperature vacuum heating box at 25°C, and evacuate it to 400Pa, and rest for 12h; 205min, turn to 1C and charge 100% for 35min, see Table 1 for cycle test.

Embodiment 3

[0040] A method for precharging a cylindrical lithium-ion battery in this embodiment specifically includes the following steps:

[0041] With nickel-cobalt lithium manganese oxide as the positive electrode and graphite as the negative electrode, the electrode assembly is made by winding with a diaphragm, put into a 18650 steel shell, and 1.3mol / L LiPF is injected into it 6 / (EC+PC+DEC) electrolyte, make battery 18650 battery, put it in a high-temperature vacuum heating box at 35°C, and evacuate to 200Pa, stand still for 96h; at room temperature at 25°C, charge 5% at 0.05C for 300min , charge 55% at 0.5C for 350min, charge 100% at 0.6C for 50min; put it in a high-temperature vacuum heating box at 25°C, and evacuate it to 400Pa, and rest for 24h; at room temperature at 10°C, discharge at 1C for 140min, charge at 0.4C for 60% 350min, turn to 0.8C to charge 100% for 50min, see Table 1 for cycle test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com