A kind of negative electrode material for sodium ion battery and preparation method thereof

A sodium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle stability and insufficient specific capacity of negative electrode materials, and achieve a good cycle Stability, increase capacity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

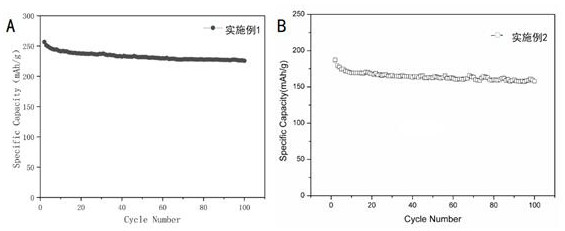

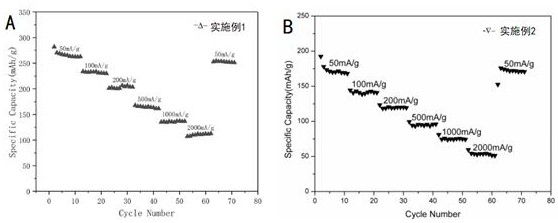

Embodiment 1

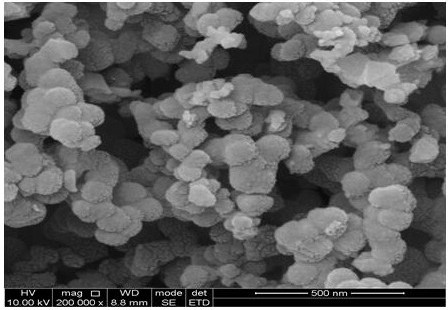

[0027] 1) Place the catalyst in a quartz boat, spread it evenly, place it in the heating tube of the device, and raise the temperature to 600 °C at a heating rate of 5 °C / min in a tube furnace filled with inert gas, turn off the inert gas, and Acetylene gas was fed at a rate of 100 mL / min. After 1 h of reaction, the acetylene gas was turned off, and an inert gas was introduced until cooled to room temperature to obtain carbon nanospheres.

[0028] 2) Weigh 0.62g of carbon nanospheres obtained in step 1) and 0.62g of SnCl 4 .5H 2 O powder was put into a sealed pulverizer and pulverized for 30 s to make the SnCl 4 .5H 2 O and nano carbon spheres were thoroughly mixed evenly. Then put the above mixture into a high-pressure hydrothermal reaction kettle, raise the temperature to 180°C at a rate of 2°C / min and keep it warm for 10 h. After cooling, wash it with a large amount of deionized water and absolute ethanol, and dry it under vacuum at 100°C for 12 h. , get NCSs / SnO 2 . ...

Embodiment 2

[0031]1) Place the catalyst in a quartz boat, spread it evenly, place it in the heating tube of the device, and raise the temperature to 600 °C at a heating rate of 5 °C / min in a tube furnace filled with inert gas, and turn off the inert gas to Acetylene gas was fed at a rate of 100 mL / min. After 1 h of reaction, the acetylene gas was turned off, and an inert gas was introduced until cooled to room temperature to obtain carbon nanospheres.

[0032] 2) Weigh 0.62g of carbon nanospheres obtained in step 1) and 0.62g of SnCl 4 .5H 2 O powder was put into a sealed pulverizer and pulverized for 30 s to make the SnCl 4 .5H 2 O and nano carbon spheres were thoroughly mixed evenly. Then put the above mixture into a high-pressure hydrothermal reaction kettle, raise the temperature to 140°C at a rate of 2°C / min and keep it for 10 h, after cooling, wash it with a large amount of deionized water and absolute ethanol, and dry it under vacuum at 100°C for 12 h , get NCSs / SnO 2 .

[00...

Embodiment 3

[0035] 1) Place the catalyst in a quartz boat, spread it evenly, place it in the heating tube of the device, and raise the temperature to 800°C at a heating rate of 6°C / min in a tube furnace filled with inert gas, and turn off the inert gas to Acetylene gas was fed at a rate of 100 mL / min. After 1 h of reaction, the acetylene gas was turned off, and an inert gas was introduced until cooled to room temperature to obtain carbon nanospheres.

[0036] 2) Weigh 0.62g of carbon nanospheres obtained in step 1) and 0.62g of SnCl 4 .5H 2 O powder was put into a sealed pulverizer and pulverized for 30 s to make the SnCl 4 .5H 2 O and nano carbon spheres were thoroughly mixed evenly. Then put the above mixture into a high-pressure hydrothermal reaction kettle, raise the temperature to 180°C at a rate of 5°C / min and keep it warm for 10 hours. After cooling, wash it with a large amount of deionized water and absolute ethanol, and dry it under vacuum at 100°C for 12 hours. , get NCSs / Sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com