Freeze drying method of azithromycin for injection

A technology of azithromycin and drying method, which is applied in the direction of freeze-drying transportation, drying solid materials, and drying solid materials without heating, etc. It can solve the problems of large difference in moisture content of azithromycin freeze-dried agent, poor uniformity of formed powder, low solubility of azithromycin, etc. , to achieve the effects of promoting conduction and heat conduction, fast forming speed, accelerated sublimation rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

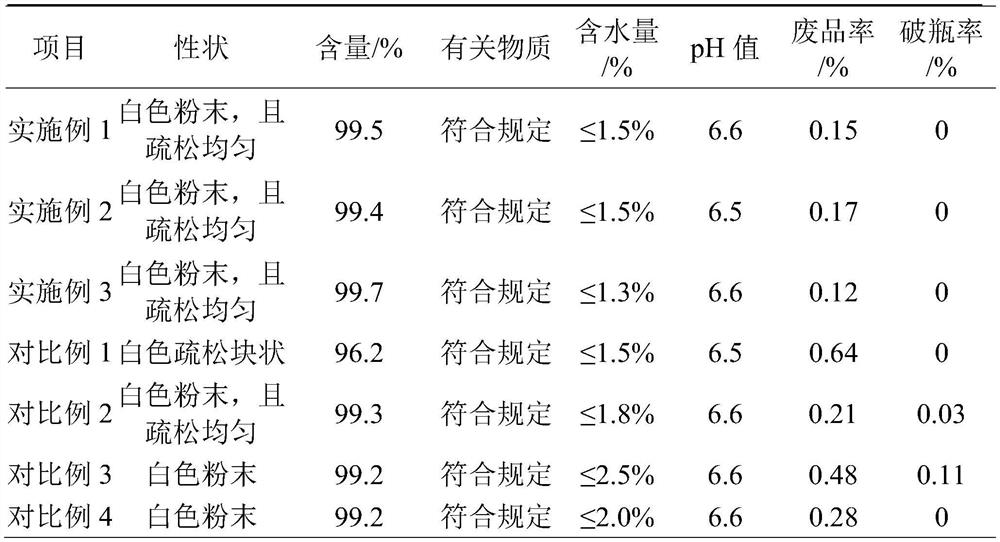

Examples

Embodiment 1

[0023] Embodiment 1-a kind of freeze-drying method of azithromycin for injection comprises the steps:

[0024] Step 1: Prepare the solution of azithromycin before lyophilization: mix azithromycin with 25% citric acid solution and 73% citric acid-sodium hydroxide mixed solution in turn, stir until clear, and use the remaining amount of citric acid solution. The citric acid solution is used as a pH regulator to adjust the pH to 6.60, and the rest is supplemented with water for injection to obtain the solution of azithromycin before lyophilization;

[0025] Among them, the prescription volume ratio of azithromycin, anhydrous citric acid, sodium hydroxide and water for injection is: 500:394:190:5548;

[0026] The citric acid-sodium hydroxide mixed solution is to add 700rmp / min of sodium hydroxide to 700rmp / min stirring and dissolving at room temperature 26 ℃ by the water for injection of prescription quantity 20%, drop to 8 ℃, add the anhydrous citric acid of prescription quantity...

Embodiment 2

[0030] Embodiment 2-a kind of freeze-drying method of azithromycin for injection comprises the steps:

[0031] Step 1: Prepare the solution of azithromycin before lyophilization: mix the azithromycin with 24.5% citric acid solution and 73.5% citric acid-sodium hydroxide mixed solution in turn, stir until clear, and use the remaining amount of citric acid solution. The citric acid solution is used as a pH regulator to adjust the pH to 6.60, and the rest is supplemented with water for injection to obtain the solution of azithromycin before lyophilization;

[0032] Among them, the prescription volume ratio of azithromycin, anhydrous citric acid, sodium hydroxide and water for injection is: 540:426:190:5548;

[0033]The citric acid-sodium hydroxide mixed solution is to add 700rmp / min of sodium hydroxide at room temperature 26 ℃ to the water for injection of 20% of the prescription quantity, stir and dissolve, then drop to 16 ℃, add anhydrous citric acid of 73.5% of the prescriptio...

Embodiment 3

[0037] Embodiment 3-a kind of freeze-drying method of azithromycin for injection comprises the steps:

[0038] Step 1: Prepare the solution of azithromycin before freeze-drying: mix the azithromycin with 24.8% citric acid solution and 73.2% citric acid-sodium hydroxide mixed solution successively, stir until clear, and use the remaining amount of citric acid solution. The citric acid solution is used as a pH regulator to adjust the pH to 6.60, and the rest is supplemented with water for injection to obtain the solution of azithromycin before lyophilization;

[0039] Among them, the prescription volume ratio of azithromycin, anhydrous citric acid, sodium hydroxide and water for injection is: 520:410:197.5:5769.5;

[0040] The citric acid-sodium hydroxide mixed solution is to add 700rmp / min of sodium hydroxide to 700rmp / min stirring and dissolving at room temperature 26 ℃ by the water for injection of prescription quantity 20%, drop to 12 ℃, add the anhydrous citric acid of pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com