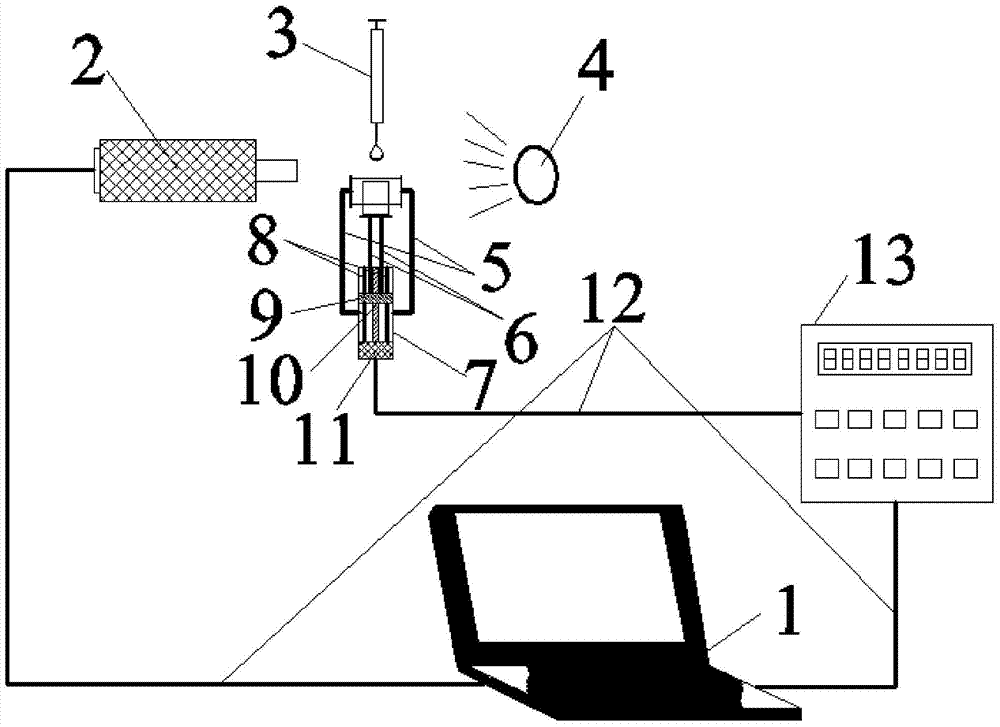

Surface wettability controllable device and control method

A control device and wettability technology, which is applied in the field of hydrophobic surface preparation, can solve the problems of not being suitable for microfluidic systems, difficulty in ultraviolet irradiation, and complicated repeated control, and achieves obvious control effect, good repeatability, and easy realization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

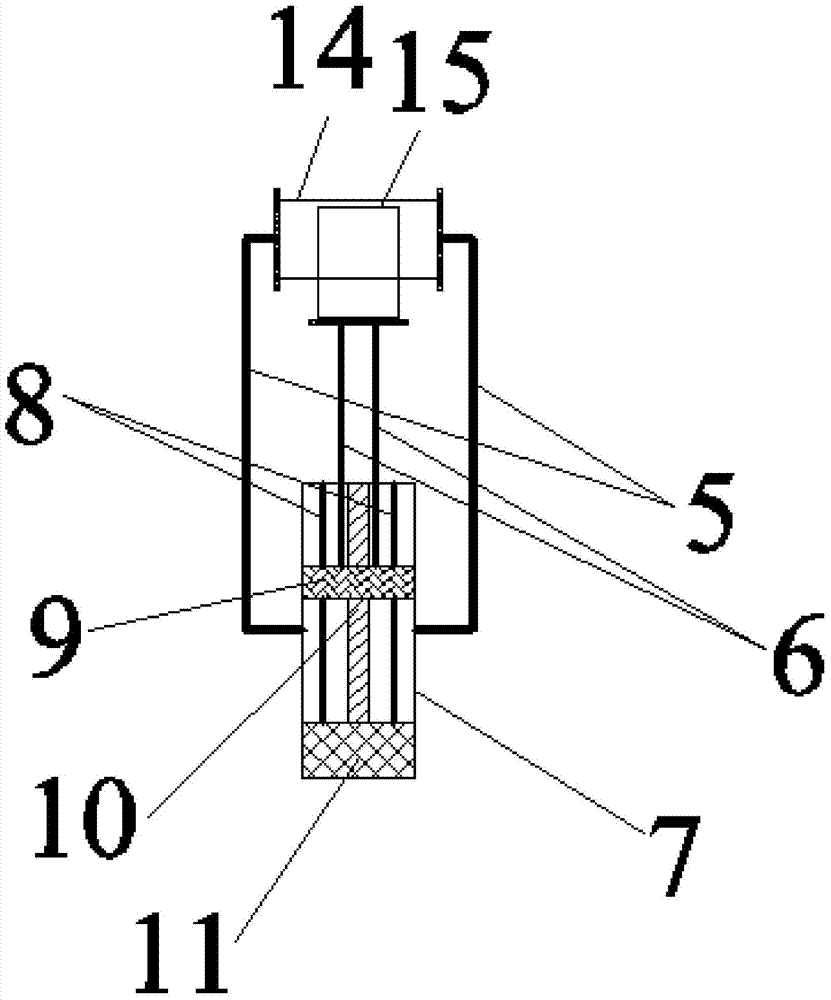

Embodiment 1

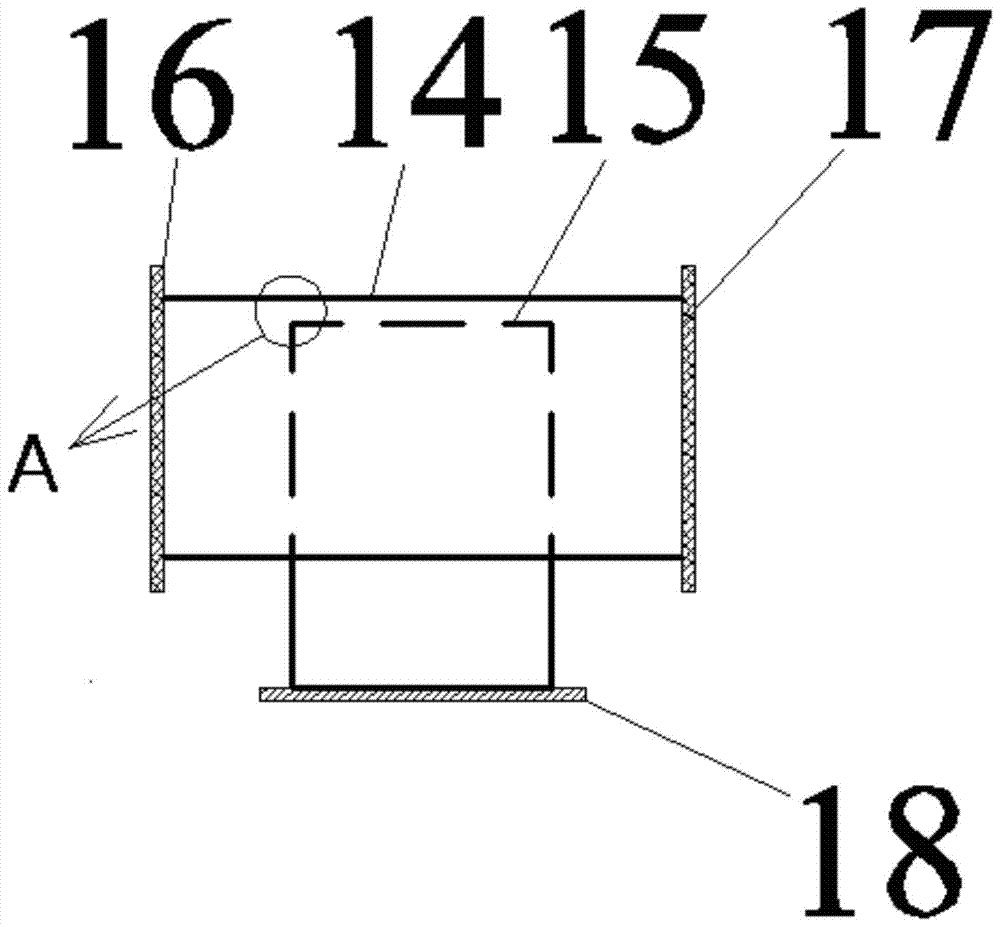

[0041] Both the sheet combination A21 and the sheet combination B22 are sheet combinations prepared from 20 sheets of 20mm (length)×10mm (width)×0.18mm (thickness), wherein the long side of the sheet combination A rectangular sheet 23 is placed horizontally, and the The short side of the rectangular sheet 24 of combination B is placed horizontally, the rectangular sheet 23 of sheet combination A and the rectangular sheet 24 of sheet combination B are in a perpendicular state to each other, after the arrangement of the sheets is completed, the left side plate 16 and the right The side plate 17 fixes the relative positions of the 20 sheet combination A rectangular sheets 23, and bonds the lower side plate 18 at the lower side of the sheet combination B22 to fix the relative positions of the 20 sheet combination B rectangular sheets 24. After the two groups of sheets are fixed, adjust the relative position of the upper surface 14 of the sheet combination A and the upper surface 15...

Embodiment 2

[0044] Both the sheet combination A21 and the sheet combination B22 are sheet combinations prepared from 20 sheets of 20mm (length)×10mm (width). The preparation process is the same as in Example 1, except that the thickness of the sheets is different. Among them, the sheet combination A is a rectangular sheet The thickness of 23 is 0.18mm, and the thickness of sheet combination B rectangular sheet 24 is 0.42mm.

[0045] The control surface 19 of the adjustable wetting mechanism is controlled and tested, and the upper surface 15 of the sheet combination B coincides with the upper surface 14 of the sheet combination A, that is, the height difference 20 between the upper surface 15 of the sheet combination B and the upper surface 14 of the sheet combination A is zero. , the measured surface contact angle is 116°; when the upper surface 15 of the sheet combination B is at different positions 0-1mm lower than the upper surface 14 of the sheet combination A, it is measured that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com