Peltier low temperature differential heat analyzer

An analyzer and micro-thermal technology, applied in the field of thermal analysis and testing, can solve the problems of high equipment cost, long control cycle, difficult control, etc., and achieve the effect of low cost, compact structure and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

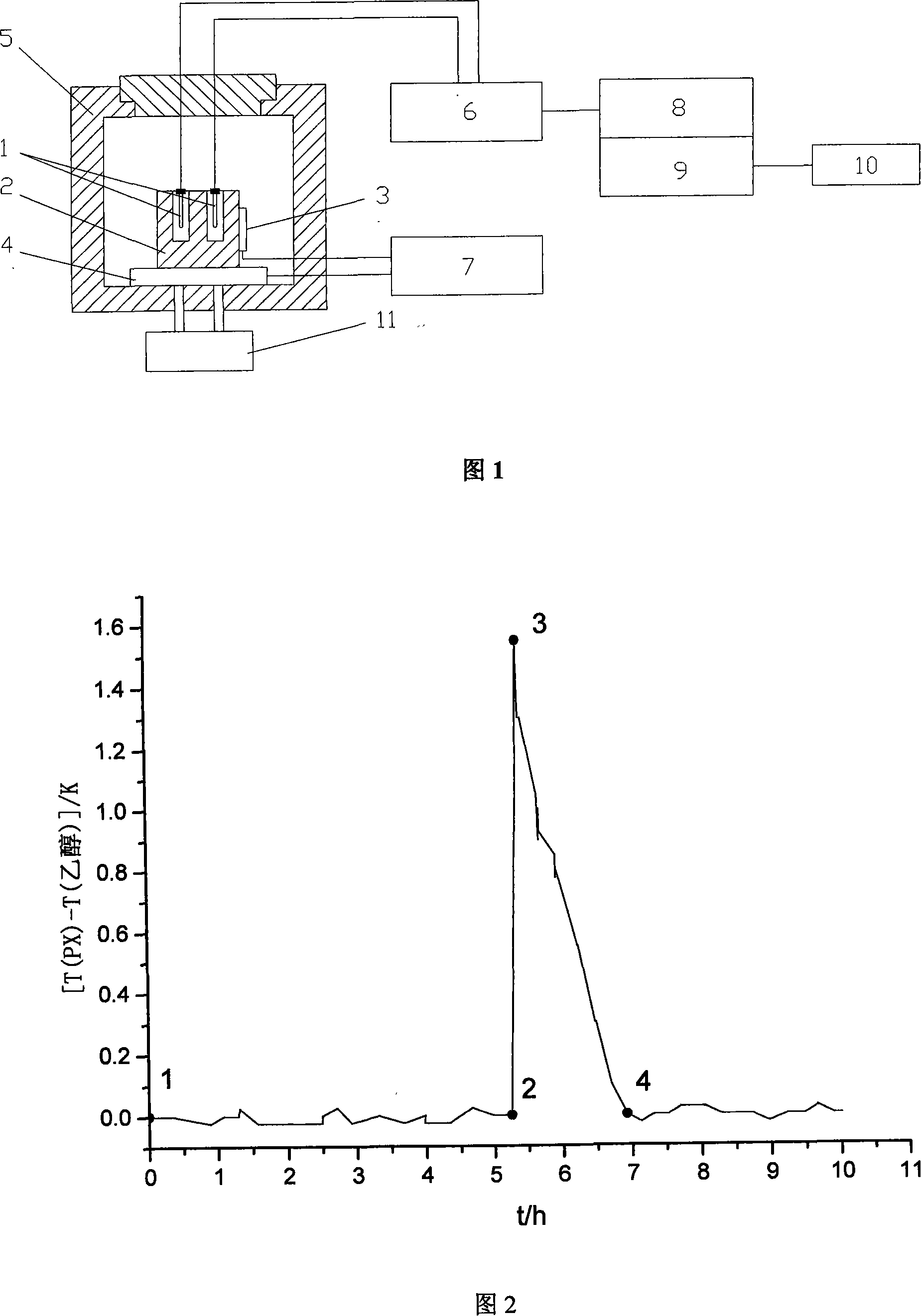

[0018] As shown in Figure 1. Connect the following components as shown in Figure 1, and those skilled in the art can implement it smoothly. This device is composed of sensor 3, crystallizer 2, chip 4, heat pump 11 and temperature / heat flow measurement and power control device 7 connected in sequence. Sensor 1 adopts Pt100 probe type platinum thermal resistance, and crystallizer adopts 35*18*25mm metal crystal Sensor 3 adopts Pt100 thin-plate platinum thermal resistance, chip 4 adopts TEC1-12704T125 semiconductor cooling chip, sealing device 5 adopts 100*100*102mm metal sealing groove, temperature / heat flow measuring device 6 adopts XMTH-7000 intelligent digital display adjustment Instrument, temperature / heat flow measurement and power control device 7 adopts TCA-808 program controller, modulus A / D conversion device 8 adopts ADAM-4015 module, computer 9 adopts P4 processor PC, printer 10 adopts Lenovo 7000 printer, heat pump 11 adopts Jiuzhou Fengshen CPU water-cooled cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com