Method for predicting residual life of in-service gas polyethylene pipelines

A life prediction, polyethylene technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure to test the strength of materials, etc. There are safety hazards and other problems in melting, which achieves the effect of low skill level requirements, less test sample volume, and convenient and quick sampling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

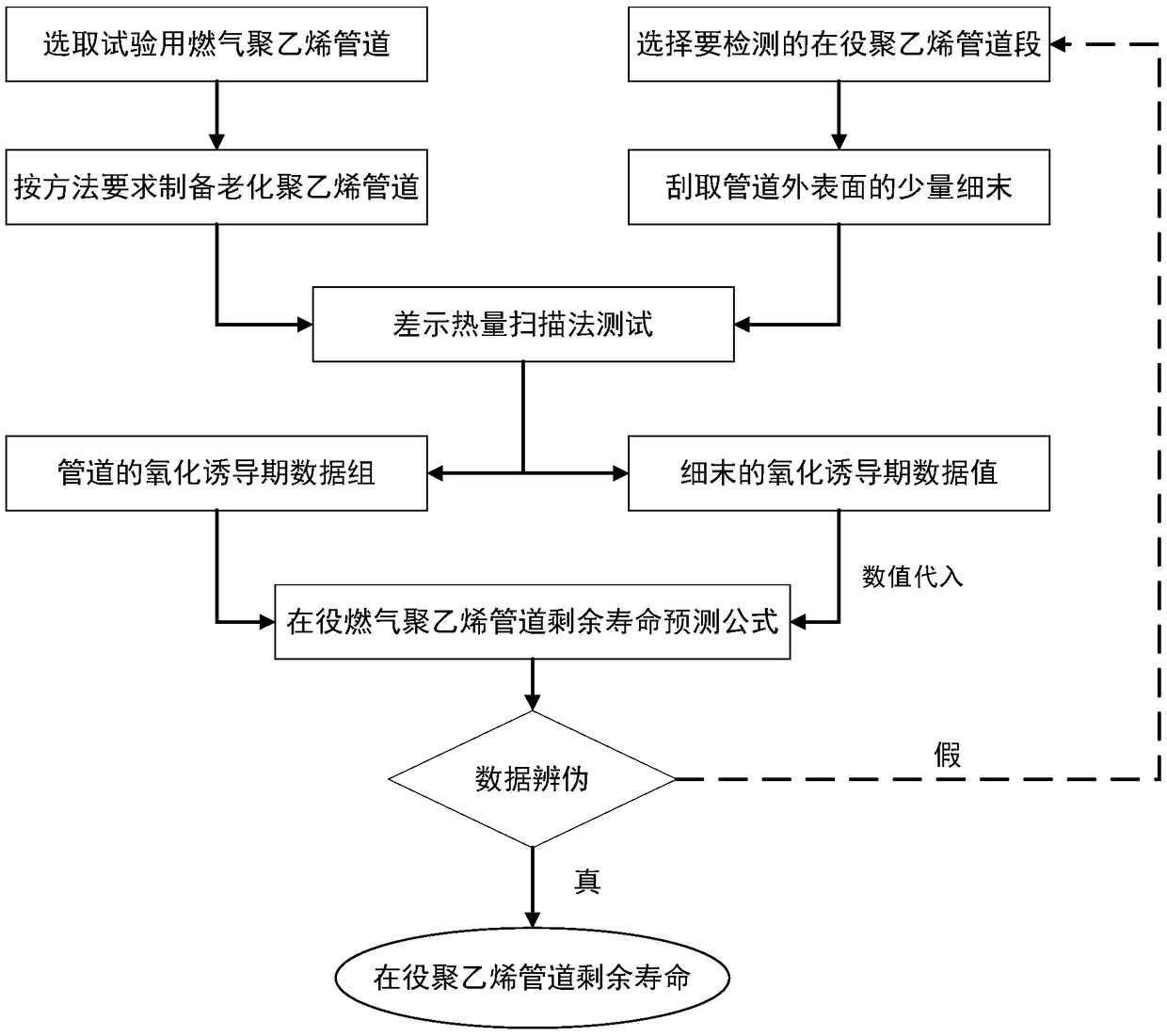

[0039] The present invention provides a method for predicting the remaining life of polyethylene gas pipelines in service. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

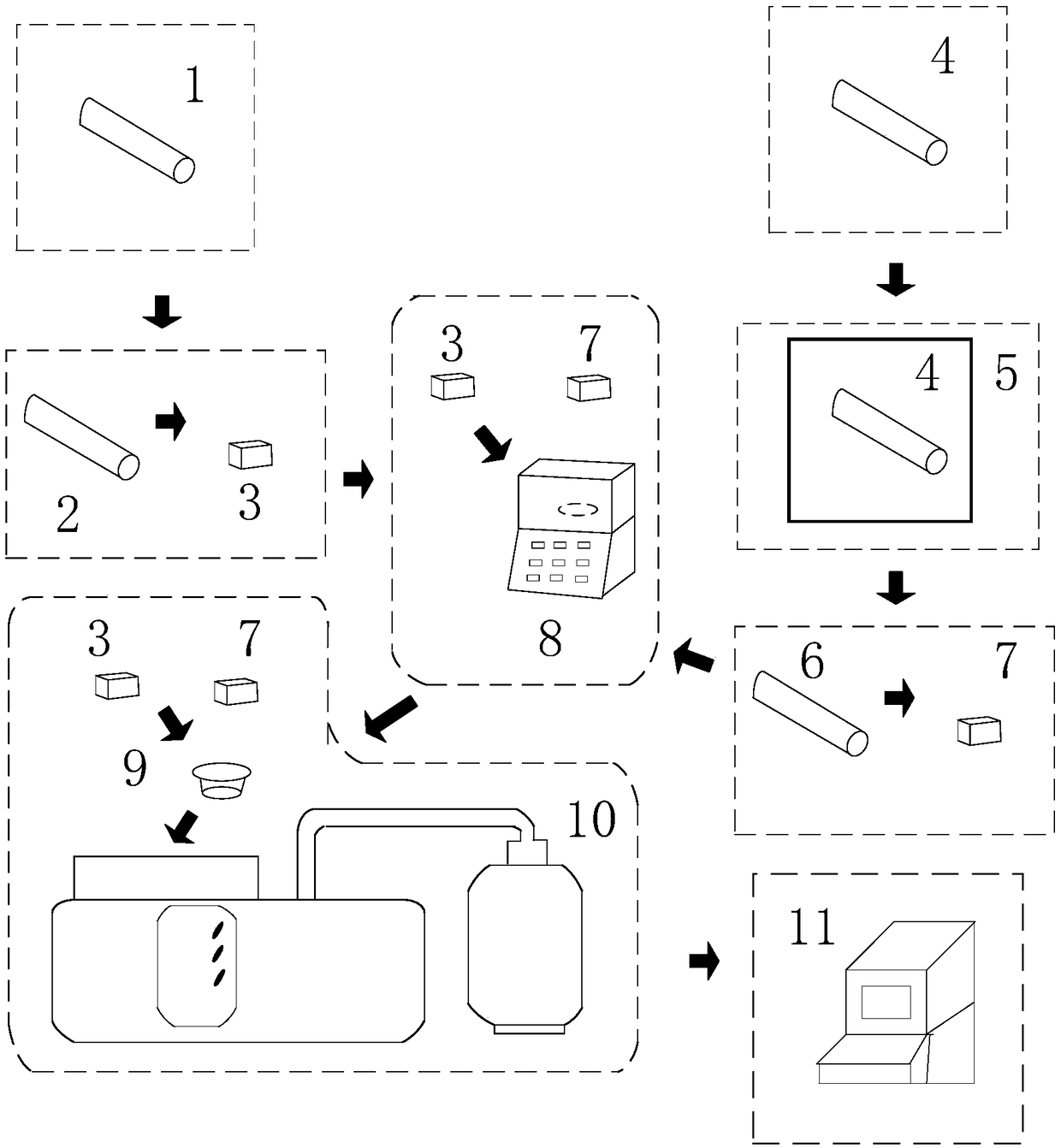

[0040] A method for predicting the remaining life of an in-service gas polyethylene pipeline provided by the present invention is as follows: figure 1As shown, the device involved in the method is composed of in-service gas polyethylene pipeline (1), in-service gas polyethylene pipeline (2), polyethylene fine particles (3), gas polyethylene pipeline (4), pressure-bearing Accelerated aging test chamber (5), aging gas polyethylene pipe (6), polyethylene fine particles (7), electronic balance (8), crucible (9), differential calorimetry scanner (10), computer (11) Composition, the in-service gas polyethylene pipeline (2) is the key area to be tested in the in-service gas polyethylene pipeline (1), and the polyethylene fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com