Method for preparing and detecting crystallization II type ammonium polyphosphate

An ammonium polyphosphate, detection method technology, applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., to achieve the effect of high accuracy and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

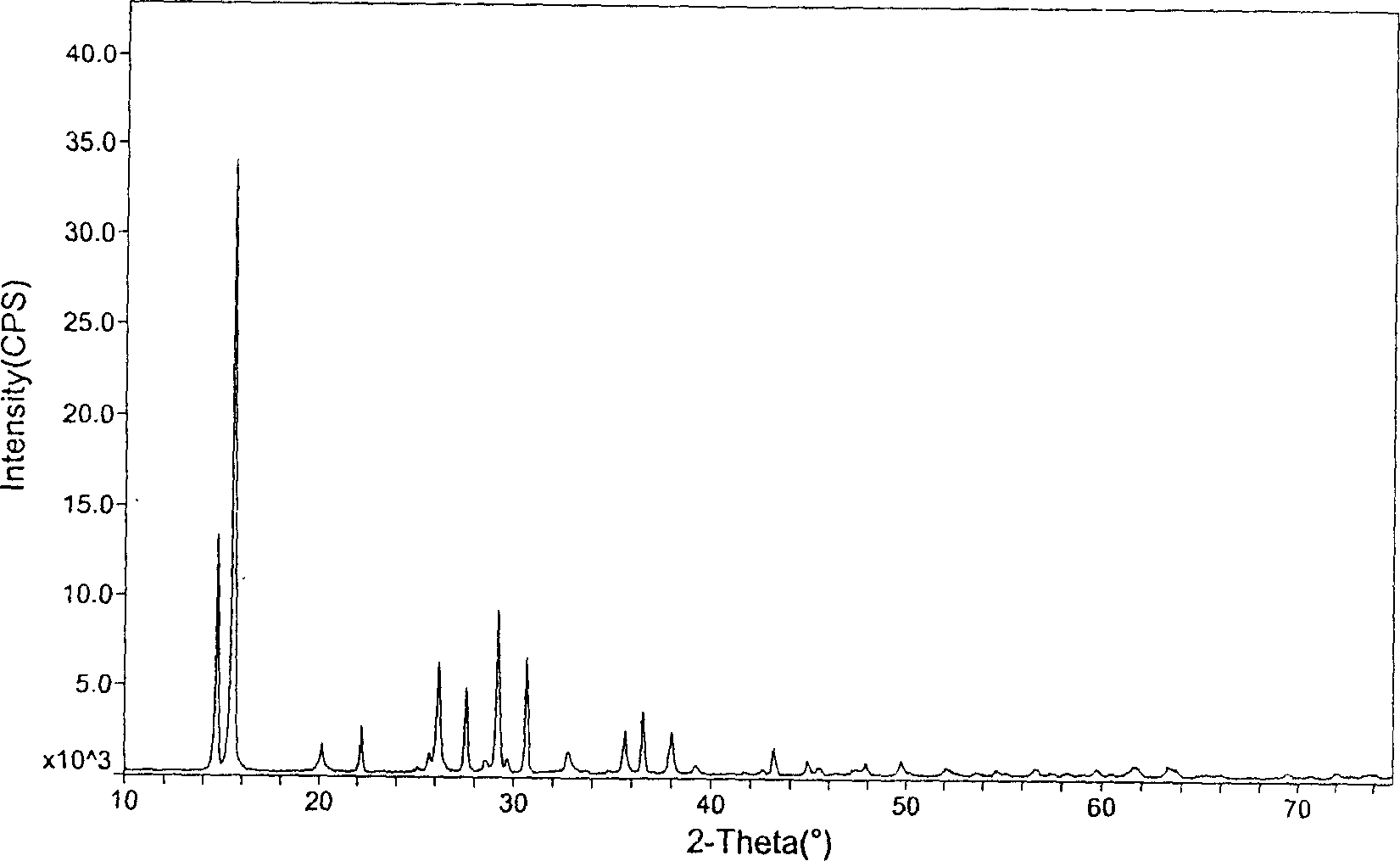

Image

Examples

Embodiment 1

[0025] Add phosphorus pentoxide 108kg, diammonium hydrogen phosphate 100kg, ammonium sulfate 1000g into 0.5m 3 In the reactor, mix for 10 minutes, then raise the temperature to 300°C, and melt at 10m 3 Ammonia gas is fed at a flow rate of / h, and the ammonia gas flow time is 1 hour, and then the ammonia flow rate is reduced to 3m 3 / h, the temperature is lowered to 250°C and then matured for 3 hours, the product obtained is 100% crystalline type II ammonium polyphosphate, the average degree of polymerization is 1313, and the thermal decomposition temperature is greater than 275°C (weight loss rate is less than 0.5%).

[0026] Preparation method embodiment 2

[0027] Add 225kg of phosphorus pentoxide, 210kg of diammonium hydrogen phosphate, and 2175g of melamine into the 1.0m 3 In the reactor, mix for 10 minutes, then raise the temperature to 300°C, melt at 20m 3 The flow rate of / h is passed through the ammonia gas, and the ammonia gas is passed for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com