Preparation method for silicon dioxide aerogel microsphere coated ammonium persulfate delaying gel-breaking agent

A technology of ammonium persulfate and silicon dioxide, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of fracturing construction failure, complex environment, melting and rupture of polymer capsule shells, etc., to improve stability and safety, the effect of solving poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

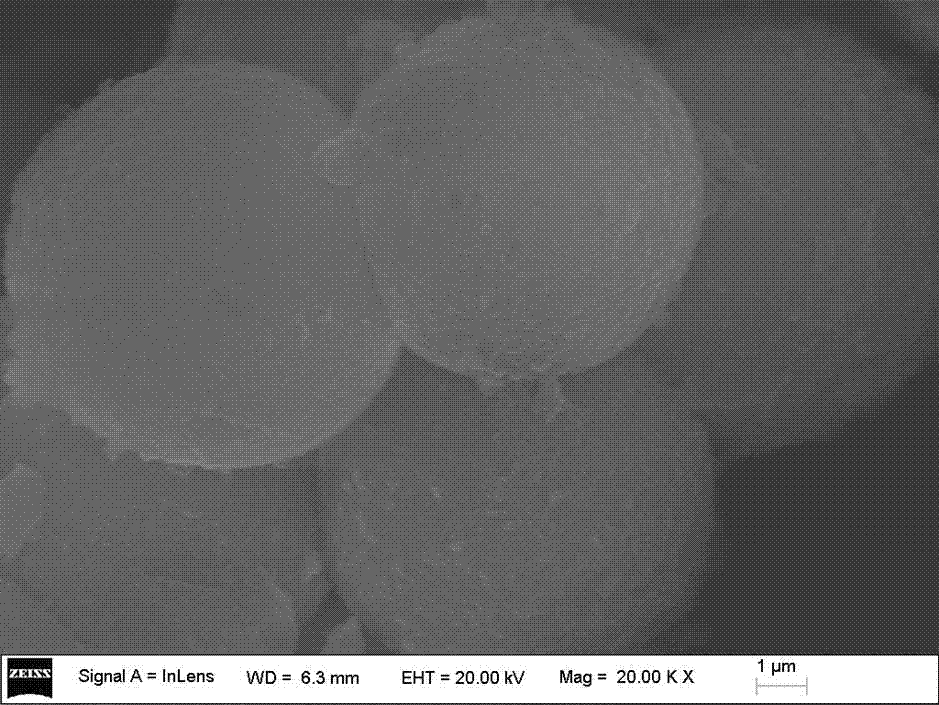

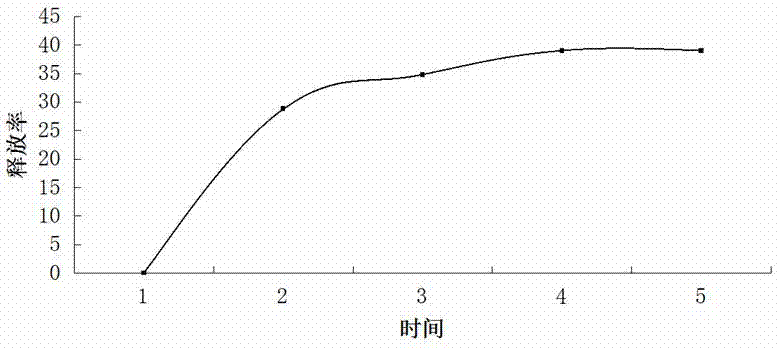

[0024] Add tetraethyl orthosilicate (TEOS) and ethanol into the beaker at a molar ratio of 1:1.04, then add 5.4ml of deionized water and 0.0242ml of concentrated nitric acid, and mix under magnetic stirring conditions. After the mixture is clarified, add 1.5 g ammonium persulfate, and continue to stir and hydrolyze for 24h.

[0025] Measure 70ml of edible oil with a measuring cylinder, and add 80 to 75ml of Span (70ml of oil phase + 5ml of surfactant) into the measuring cylinder, pour it into a beaker equipped with a magnetic rotor, and stir with a mixer until uniform. After stirring evenly, slowly add the hydrolyzate, set the stirring speed to 650r / min, and stir until uniform. Reduce the rotational speed, slowly add 2ml of ammonia water to adjust the pH, and maintain stirring for a period of time under the condition of a stirring speed of 700r / min. After stirring evenly, cover the mouth of the beaker with plastic wrap and let stand for 8h.

[0026] Use n-hexane as a cleanin...

Embodiment 2

[0031] Add tetraethyl orthosilicate (TEOS) and ethanol into the beaker at a molar ratio of 1:1.04, then add 5.4ml of deionized water and 0.0242ml of concentrated nitric acid, mix under magnetic stirring conditions, and add 1.0ml after the mixture is clarified g ammonium persulfate, and continue to stir and hydrolyze for 24h.

[0032] Measure 70ml of edible oil with a measuring cylinder, and add 80 to 75ml of Span (70ml of oil phase + 5ml of surfactant) into the measuring cylinder, pour it into a beaker equipped with a magnetic rotor, and stir with a mixer until uniform. After stirring evenly, slowly add the hydrolyzate, set the stirring speed to 650r / min, and stir until uniform. Reduce the rotational speed, slowly add 2ml of ammonia water to adjust the pH, and maintain stirring for a period of time under the condition of a stirring speed of 700r / min. After stirring evenly, cover the mouth of the beaker with plastic wrap and let stand for 8h.

[0033] Use n-hexane as a cleani...

Embodiment 3

[0035] Add tetraethyl orthosilicate (TEOS) and ethanol into the beaker at a molar ratio of 1:1.04, then add 5.4ml of deionized water and 0.0242ml of concentrated nitric acid, and mix under magnetic stirring conditions. After the mixture is clarified, add 0.5 g ammonium persulfate, and continue to stir and hydrolyze for 24h.

[0036] Measure 70ml of edible oil with a measuring cylinder, and add 80 to 75ml of Span (70ml of oil phase + 5ml of surfactant) into the measuring cylinder, pour it into a beaker equipped with a magnetic rotor, and stir with a mixer until uniform. After stirring evenly, slowly add the hydrolyzate, set the stirring speed to 650r / min, and stir until uniform. Reduce the rotation speed, slowly add 2ml drops of ammonia water to adjust the pH, and keep stirring for a period of time under the condition of stirring speed of 700r / min. After stirring evenly, cover the mouth of the beaker with plastic wrap and let stand for 8h.

[0037] Use n-hexane as a cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com