Bonding sheet and preparation method thereof

A bonding sheet, high thermal conductivity technology, applied in the direction of adhesive, adhesive type, film/sheet release liner, etc., can solve the problem of low modulus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

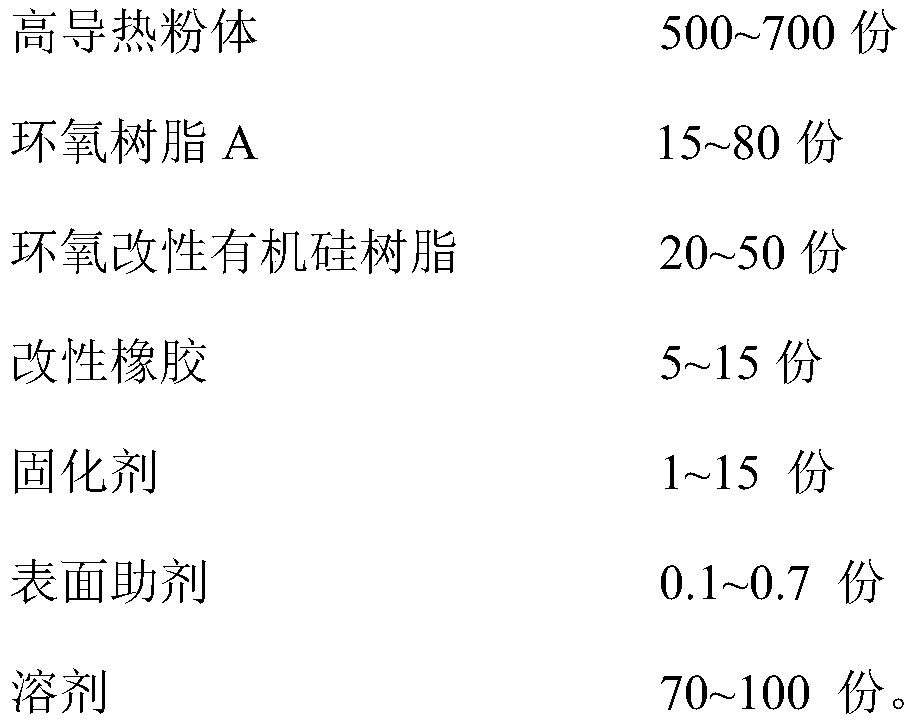

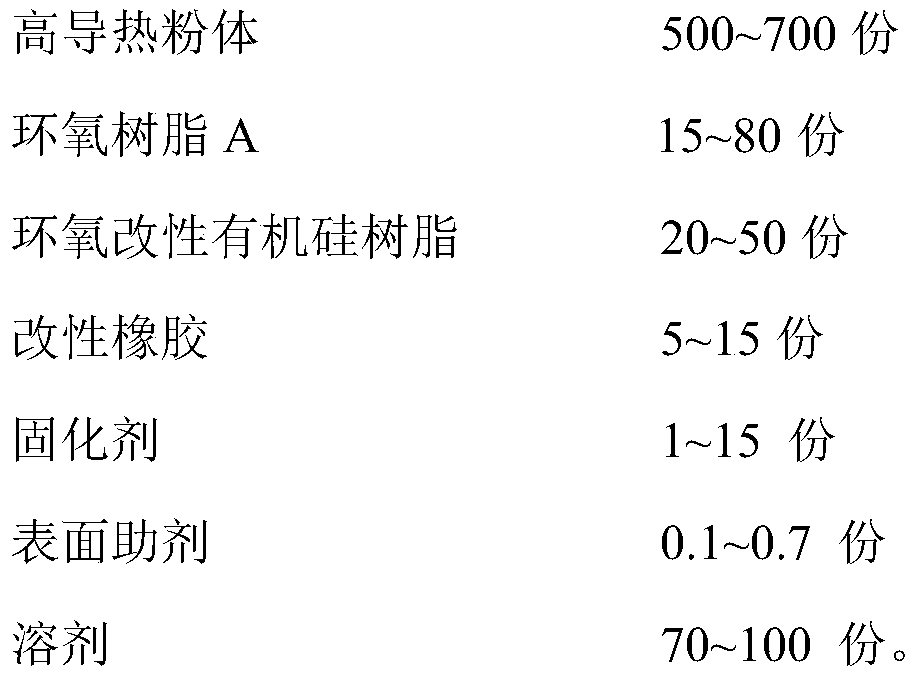

Method used

Image

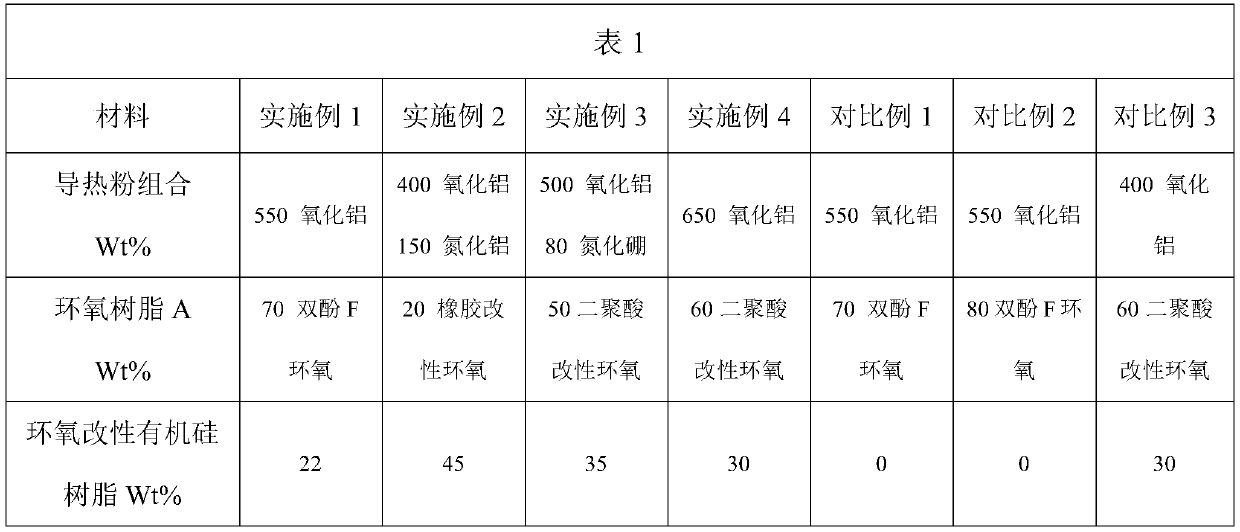

Examples

Embodiment 1

[0033] Step (1) 30Wt%N, N-dimethylformamide+50Wt% ethyl ketone solvent solvent combination, 1.8Wt% dicyandiamide curing agent, 70Wt% bisphenol F, 22Wt% organosilicon epoxy resin , 13Wt% carboxy-terminated nitrile rubber, 0.4Wt% surface additives are mixed and stirred to obtain pure rubber combination;

[0034] Step (2): Add 550Wt% of the high thermal conductivity powder combination into the pure rubber combination of the step (1); respectively go through 1500 rpm high-speed shear stirring, 500 rpm + forward rotation and reverse rotation for 30 minutes respectively Zirconia ball milling, 400 rpm low-speed defoaming and other steps to obtain uniformly dispersed high thermal conductivity glue;

[0035] Step (3): Coat the high thermal conductivity glue in the step (2) on a 50 μm release film through a wire rod of a specific specification, let it stand at room temperature for 3 minutes, put it in an oven at 160°C for 5 minutes and bake it Drying and pre-curing to obtain a 100μm ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com